A kind of solid solution type Fexco1-xs2 cathode material for thermal battery and preparation method thereof

A fexco1-xs2, cathode material technology, applied in the field of material chemistry, can solve the problems of uncontrolled component ratio, low content, affecting the safety and reliability of thermal batteries, etc., to reduce design difficulty, single component, change material chemistry Effects of Activity and Thermodynamic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The target product is solid solution Fe for thermal batteries x co 1-x S 2 The weight ratio of the active components of the positive electrode material is: Fe accounts for 26%; Co accounts for 64%. First, according to the ratio of 60wt% Al powder, 18wt% Fe powder, and 42wt% Co powder, three kinds of powders were weighed, mixed and put into a ball mill for 12h, and the powders were taken out and placed in the Ar 2 Tumble dry under cover. The dried powder was packed into a quartz tube, and the Ar 2 Heating to 1000°C under protection for melting; melting the alloy with Ar 2 Spray it onto a copper roller that rotates at a high speed (500rpm) and is passed through with cooling water, so that the alloy is rapidly cooled to obtain a strip-shaped alloy product; the fragile alloy strip is crushed, and 100-200 mesh FeCoAl alloy is sieved. Heat 20wt% NaOH aqueous solution to 85°C, slowly add FeCoAl alloy into the NaOH solution according to the ratio of 100g / L and stir for 2 h...

Embodiment 2

[0025] The target product is solid solution Fe for thermal batteries x co 1-x S 2 The weight ratio of the active components of the positive electrode material is: Fe accounts for 34%; Co accounts for 55%. First, according to the ratio of 60wt% Al powder, 24wt% Fe powder, and 36wt% Co powder, three kinds of powders were weighed, mixed and put into a ball mill for 12 hours, and the powders were taken out and placed in the Ar 2 Tumble dry under cover. The dried powder was packed into a quartz tube, and the Ar 2 Heating to 1000°C under protection for melting; melting the alloy with Ar 2 Spray it onto a copper roller that rotates at a high speed (900rpm) and passes through cooling water, so that the alloy is rapidly cooled to obtain a strip-shaped alloy product; the fragile alloy strip is crushed, and 100-200 mesh FeCoAl alloy is sieved. Heat 20wt% NaOH aqueous solution to 90°C, slowly add FeCoAl alloy to the NaOH solution at a ratio of 100g / L and stir for 2 hours, so that the...

Embodiment 3

[0027] The target product is solid solution Fe for thermal batteries x co 1-x S 2 The weight ratio of the active components of the positive electrode material is: Fe accounts for 43%; Co accounts for 46%. Firstly, three kinds of powders were weighed according to the ratio of 60wt% Al powder, 30wt% Fe powder, and 30wt% Co powder, mixed them, put them into a V-shaped powder mixer, mixed them and dried them. The dried powder was packed into a quartz tube, and the Ar 2 Heating to 1000°C under protection for melting; melting the alloy with Ar 2 Spray it onto a copper roller that rotates at a high speed (1500rpm) and is passed through with cooling water, so that the alloy is rapidly cooled to obtain a strip-shaped alloy product; the fragile alloy strip is crushed, and 100-200-mesh FeCoAl alloy is sieved. Heat 20wt% NaOH aqueous solution to 85°C, slowly add FeCoAl alloy to the NaOH solution according to the ratio of 95g / L and stir for 2 hours, so that the Al in the alloy is fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

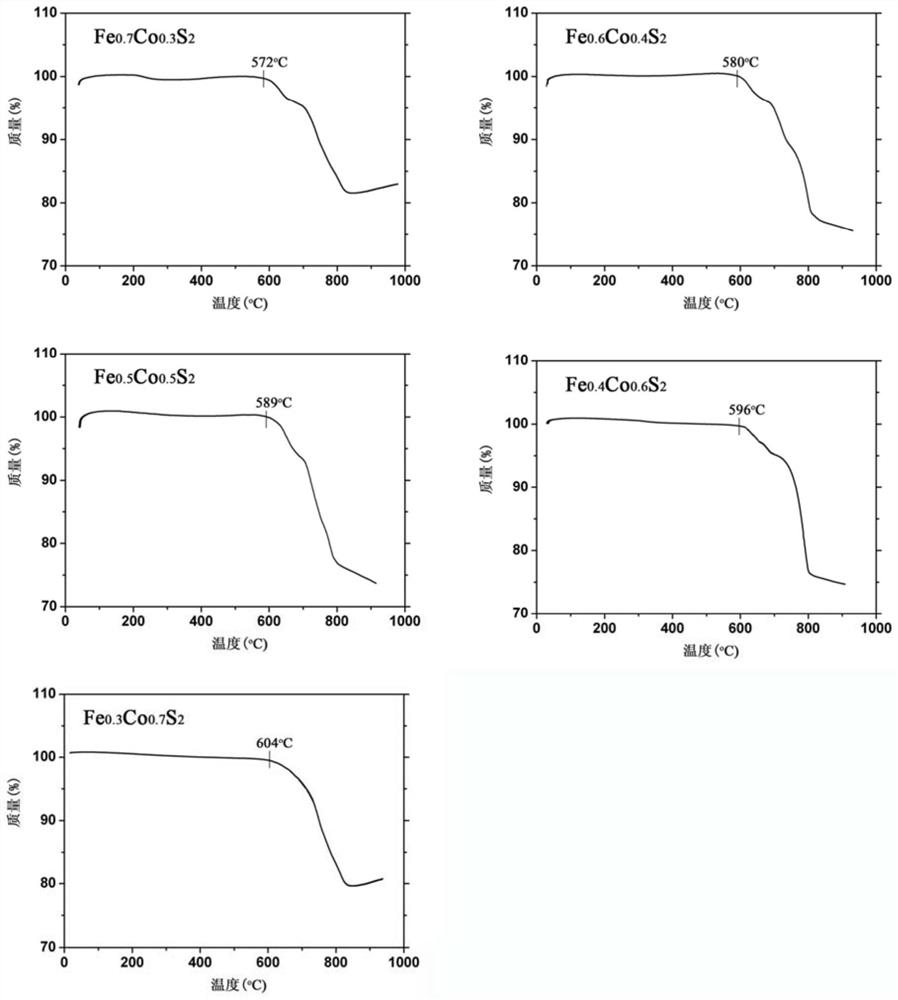

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com