pt modified fe2o3 wrapped cufeo2 photocathode and its preparation method

A photocathode, fe2o3 technology, applied in the field of photoelectrochemistry, can solve the problems of electrical conductivity and light transmittance damage, unfavorable photogenerated carrier transport, large difference in work function, etc., to achieve high photocurrent density and improve photolysis. Hydrogen production efficiency from water and the effect of low production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Pt-modified Fe 2 o 3 Coated CuFeO 2 The preparation method of photocathode comprises the following steps:

[0048] Step 1. Weigh the prepared CuFeO by weight ratio 4:1-5:1 2 After the powder and iodine powder are mixed, they are put into the acetone solution to prepare an electrophoretic deposition suspension with a weight ratio of 1:1-1:1.5, and the mixed suspension is ultrasonically oscillated in an ultrasonic cleaner for 15-20 minutes to obtain a mixed homogeneous suspension;

[0049] Step 2. Make a piece with an area of 2-4cm 2 , surface cleaned ITO conductive glass substrate 1 and an area of 8-10cm 2 Put the graphite electrode sheet in parallel into the suspension prepared in step 1. The distance between the ITO conductive glass substrate 1 and the graphite electrode sheet is 1-1.5cm. The ITO conductive glass substrate 1 is connected to the positive electrode, and the graphite electrode sheet is connected to the negative electrode. The stabilized power su...

Embodiment 1

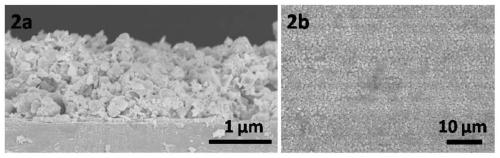

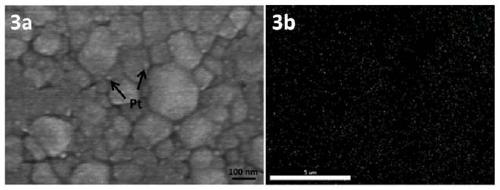

[0056] Such as Figure 1-9 As shown, Pt modified Fe 2 o 3 Coated CuFeO 2 Photocathode, layer by layer from the surface down to Pt catalyst particle layer 3, Fe 2 o 3 Coated CuFeO 2 Particle film layer 2, ITO conductive glass substrate 1, Pt particles in Pt catalyst particle layer 3 are deposited on Fe 2 o 3 Coated CuFeO 2 Particle film layer 2 surface, Fe 2 o3 Coated CuFeO 2 Fe in particle film layer 2 2 o 3 with CuFeO 2 form a wrapping structure between them, and the Fe on the surface 2 o 3 in CuFeO 2 A transition layer is formed between the Pt catalyst particle layer 3 .

[0057] Deposit a layer of CuFeO on the ITO conductive glass substrate 1 by electrophoretic deposition 2 granular layer, followed by a sol-gel method on CuFeO 2 The surface of the granular layer was treated with plastic rejection for 5 times, and Fe was obtained after annealing. 2 o 3 Coated CuFeO 2 Particle film layer 2, and finally, using the photoreduction method on the Fe 2 o 3 Coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com