Tea seed oil squeezing production system and production method

A technology of production system and production method, which is applied in the direction of fat oil/fat production, fat generation, fat oil/fat refining, etc. It can solve the problems of product turbidity, unfavorable refrigerated storage, low oil yield, etc., and achieve the effect of obvious removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

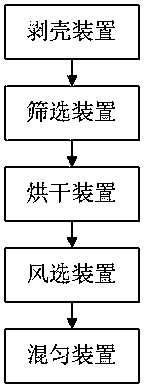

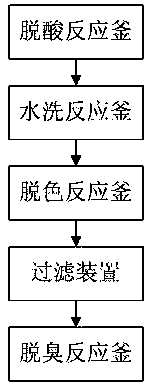

[0067] Embodiment 1 provides a kind of production system of pressing tea seed oil, see figure 1 and 2 , the system includes a pretreatment section, an oil extraction section and a refining section; the pretreatment section is used for shelling, screening, drying and winnowing of Camellia oleifera seeds; the oil extraction section is used for low-temperature extraction to obtain crude oil; the refining section It is used to refine crude oil to obtain tea seed oil exceeding the national standard (GB11765-2003) of camellia seed oil pressed primary oil. The pretreatment section includes a shelling device, a screening device, a drying device, and a wind separation device 6 that are sequentially connected through a conveyor belt or a bucket elevator (for example, a third bucket elevator 5 is installed between the drying device and the air separation device 6). and mixing device, etc., can be located in the same workshop (drying workshop); the oil extraction section includes crushin...

Embodiment 2

[0082] Embodiment 2 provides a production method of pressed tea seed oil. The method includes a pretreatment section, an oil extraction section and a refining section, and the pretreatment section includes steps such as shelling, screening, drying and winnowing in sequence. Wherein, the drying process includes drying the moisture content of the camellia seed to 8-10% by using a drying device.

[0083] Among them, see Figure 12 , the oil pressing section includes the following processes:

[0084] 201 Pulverization: using a pulverization device to pulverize the Camellia oleifera seeds from the pretreatment section or refrigerated after being treated in the pretreatment section to a size of 0.15-0.25 mm, to obtain Camellia oleifera seed powder and send to step 202.

[0085] 202 Rolling: use a rolling device to roll the camellia seed powder processed in step 201 to 0.05-0.15 mm, and send to step 203. The rolling process can increase the oil yield of crude oil by 1-2%, and facil...

Embodiment 3

[0103] Embodiment 3 provides a kind of production method of pressing tea seed oil, and the method comprises the following steps:

[0104] Among them, see Figure 11 , the pretreatment section includes:

[0105] 101 Shelling: the shelling device is used to break the shell to separate the nuts.

[0106] 102 Screening: Use a screening device (such as a vibrating screen) to separate the shells, so that the shell rate in the camellia seed kernel is below a certain value.

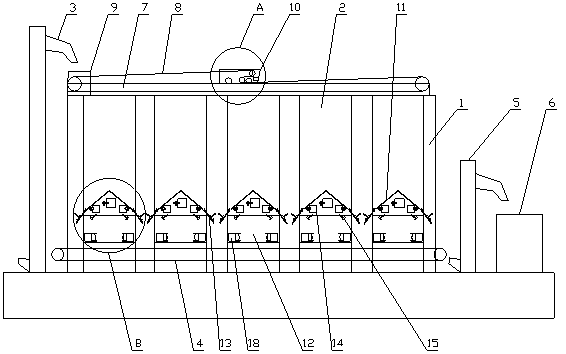

[0107] 103 Drying: Lay tea oil seeds in the drying chamber with a thickness of 2m and an inverted V-shaped mesh plate 11 with a height of 0.5m; in the first 6 hours, the feed and upper exhaust port 19 are opened, and the lower exhaust port 14 is closed. The upper hot air inlet 16 is closed, the lower hot air inlet 17 is fed with 30°C hot air; after 2 hours, the feed and upper exhaust port 19 are closed, the lower exhaust port 14 is opened, the upper hot air inlet 16 is fed with 30°C hot air, and the lower hot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com