Sulfur-resistant water-resistant, dust removal, denitration and demercuration multifunctional filter material and preparation method thereof

A multi-functional, water-based dedusting technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems that hinder the development and application of denitrification and demercury catalysts, the particles are easy to block the catalyst pores, catalyst poisoning, etc., to achieve isolation deposition and Poisoning effect, excellent water resistance and sulfur poisoning performance, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

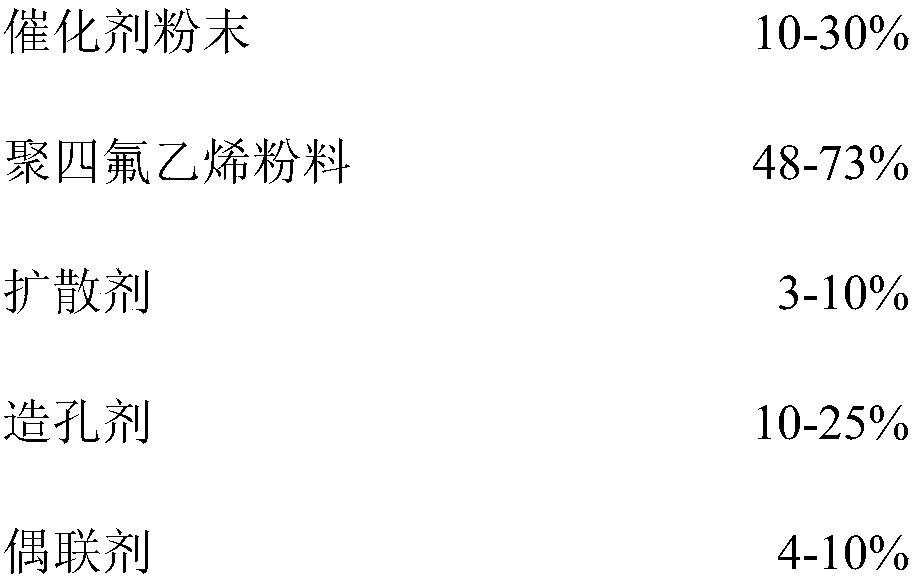

Method used

Image

Examples

preparation example Construction

[0033] 1. Preparation of catalyst powder

[0034] ① According to the catalyst active components (Ti-Sn-Nb-Ce-O x ) composite oxide and catalytic promoter (Fe-La-Co-O x) The mass ratio of composite oxide is 1:0.2, the molar ratio of Ti / Sn / Nb / Ce element is 1:0.1:0.1:0.1, and the molar ratio of Fe / La / Co element is 1:0.1:0.1, respectively weigh titanium Butyl nitrate, cerium nitrate, tin tetrachloride, cobalt acetate, copper nitrate, iron nitrate, niobium oxalate, lanthanum nitrate. The first step is to mix butyl titanate with absolute ethanol to obtain liquid A, and mix glacial acetic acid, absolute ethanol, distilled water and other salts to obtain liquid B; the second step is to add B solution to uniformly stirred liquid A , magnetically stirred for 10 min, and then aged for 48 h.

[0035] ②Dry the aged solution at 60°C for 10 hours, then put it into a muffle furnace for calcination, the calcination temperature is 800 ℃, the calcination time is 2 hours, and the denitrificati...

Embodiment 2

[0060] 1. Preparation of catalyst powder

[0061] ① According to the catalyst active components (Ti-Sn-Nb-Ce-O x ) composite oxide and catalytic promoter (Fe-La-Co-O x ) The mass ratio of composite oxide is 1:0.2, the molar ratio of Ti / Sn / Nb / Ce element is 1:0.2:0.2:0.25, and the molar ratio of Fe / La / Co element is 1:0.25:0.25, respectively weigh titanium Butyl nitrate, cerium sulfate, tin tetrachloride, cobalt nitrate, copper nitrate, iron nitrate, niobium oxalate, lanthanum acetate. The first step is to mix butyl titanate with absolute ethanol to obtain liquid A, and mix glacial acetic acid, absolute ethanol, distilled water and other salts to obtain liquid B; the second step is to add B solution to uniformly stirred liquid A , magnetically stirred for 20 min, and then aged for 30 h.

[0062] ②Dry the aged solution at 75°C for 8 hours, then put it into a muffle furnace for calcination, the calcination temperature is 550 ℃, the calcination time is 4.5h, and the denitrificati...

Embodiment 3

[0078] 1. Preparation of catalyst powder

[0079] ① According to the catalyst active components (Ti-Sn-Nb-Ce-O x ) composite oxide and catalytic promoter (Fe-La-Co-O x) The mass ratio of composite oxide is 1:0.2, the molar ratio of Ti / Sn / Nb / Ce element is 1:1:1:1, and the molar ratio of Fe / La / Co element is 1:1:1, respectively weigh titanium Butyl nitrate, cerium sulfate, tin tetrachloride, cobalt nitrate, copper nitrate, iron nitrate, niobium oxalate, lanthanum acetate. The first step is to mix butyl titanate with absolute ethanol to obtain liquid A, and mix glacial acetic acid, absolute ethanol, distilled water and other salts to obtain liquid B; the second step is to add B solution to uniformly stirred liquid A , magnetically stirred for 30 min, and then aged for 24 h.

[0080] ②Dry the aged solution at 80°C for 2h, then put it into a muffle furnace for calcination, the calcination temperature is 350°C, the calcination time is 10h, and the denitrification and mercury remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com