Anti-corrosion construction method of low-order flash chamber of phosphoric acid flash cooling system

A construction method and flash chamber technology, applied in flash evaporation, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve problems such as short maintenance period, unstable anti-corrosion layer, easy to be corroded and perforated, etc. Achieve the effect of reducing equipment and equipment operating costs, increasing mechanical strength and corrosion resistance, extending service life and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

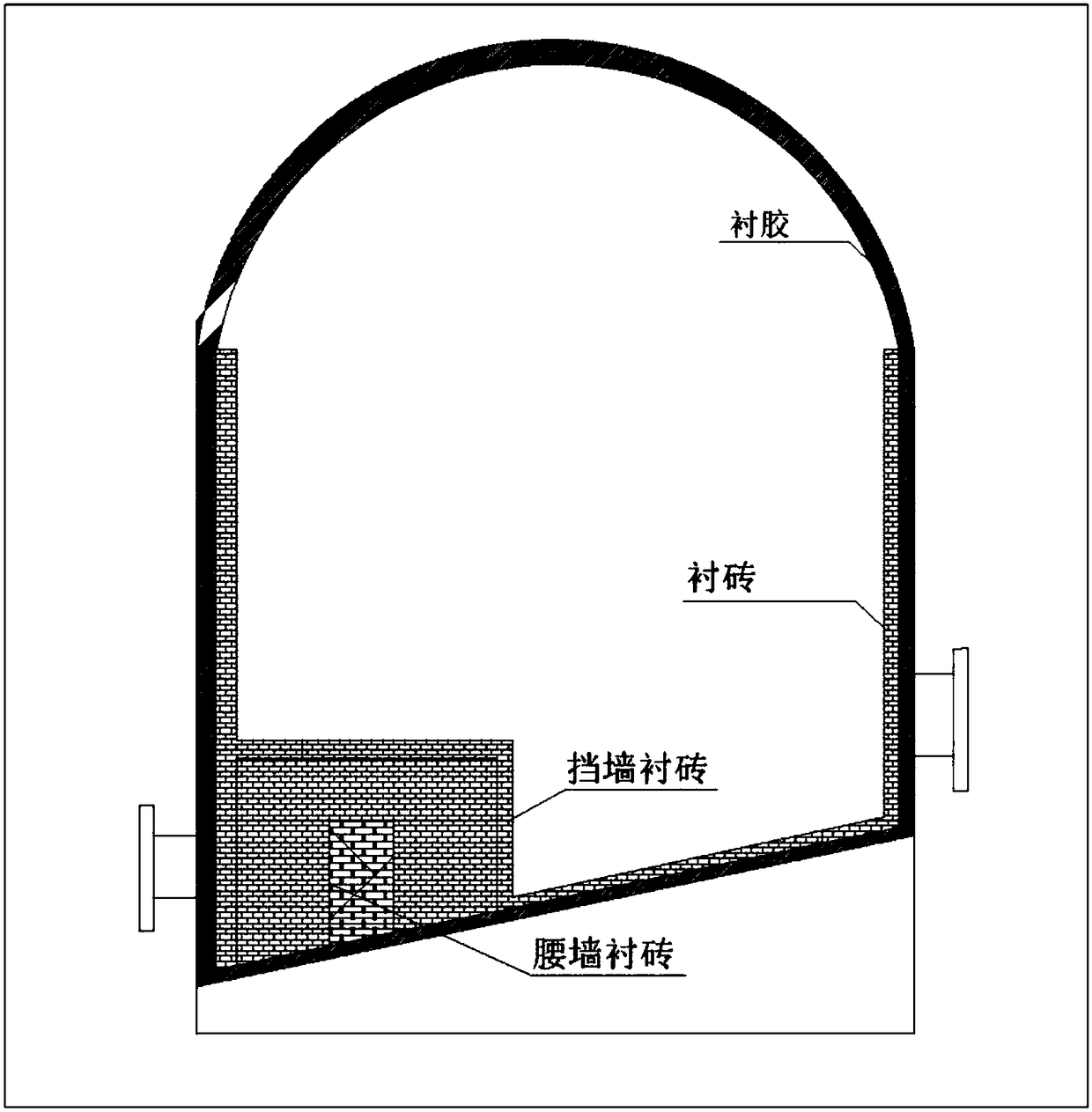

[0044] An anti-corrosion construction method for a low-level flash chamber of a phosphoric acid flash cooling system, including rubber lining and brick lining, specifically comprising the following steps:

[0045] 1. Rubber lining:

[0046] (1) Carry out sandblasting treatment to the inner wall, bottom and baffle plate of the low-level flash evaporation; the roughness of the inner wall, bottom and baffle plate of the low-level flash evaporation after the sandblasting treatment is 60 μm;

[0047] (2) Use cleaning agent to scrub the inner wall, bottom and baffle of the low-level flash chamber, and apply primer and adhesive;

[0048] (3) Lining unvulcanized rubber, pressurized steam vulcanization; the vulcanization process is constant temperature treatment at 0.3Mpa, 125°C for 6h; the thickness of the lining unvulcanized rubber is 4mm, and the unvulcanized rubber is HF-D ;

[0049] The rubber lining is D3 rubber lining;

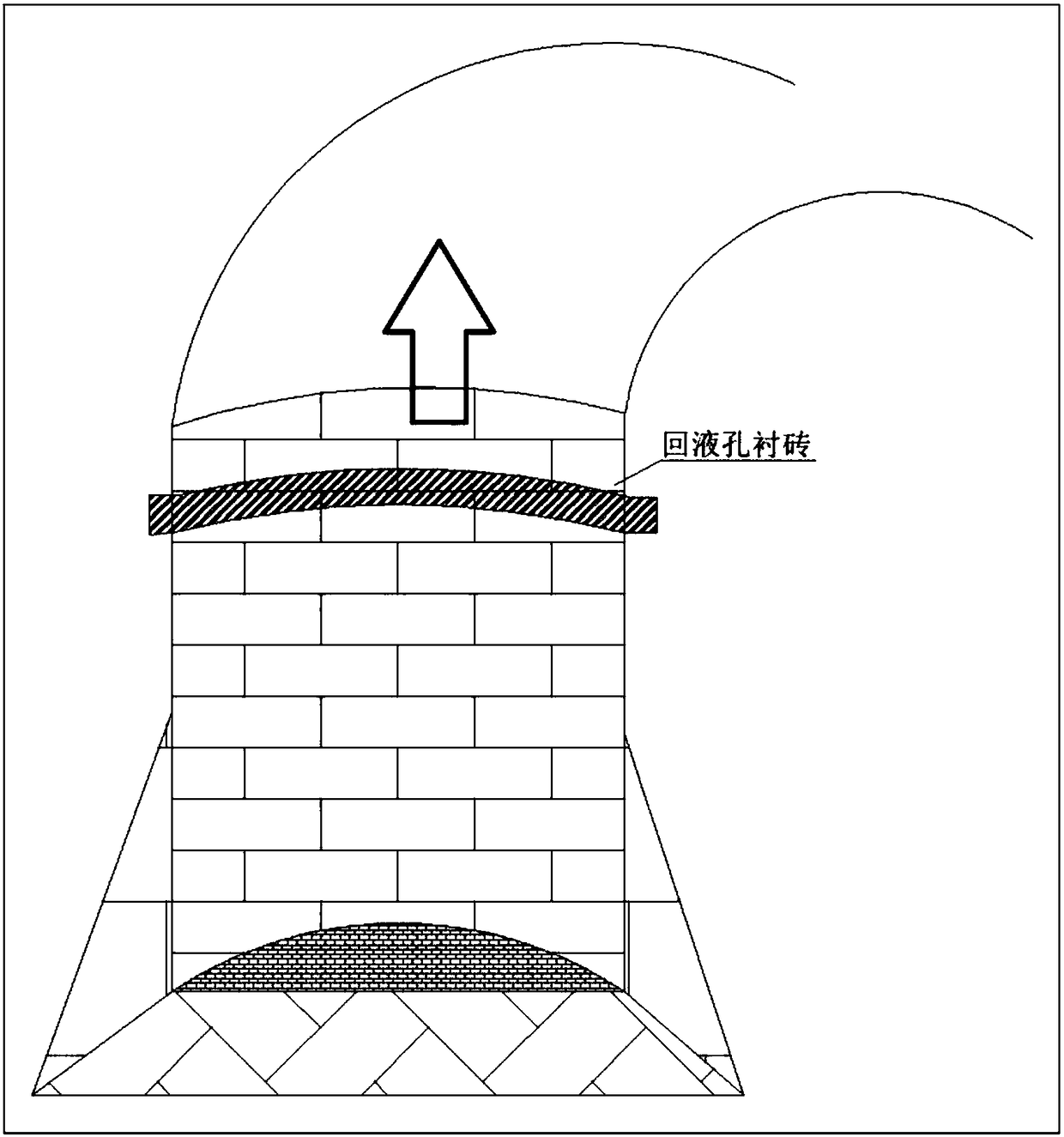

[0050] 2. Lining bricks: including lining bricks for th...

Embodiment 2

[0061] An anti-corrosion construction method for a low-level flash chamber of a phosphoric acid flash cooling system, including rubber lining and brick lining, specifically comprising the following steps:

[0062] 1. Rubber lining:

[0063] (1) Carry out sandblasting treatment to the inner wall, bottom and baffle plate of the low-level flash evaporation; the roughness of the inner wall, bottom and baffle plate of the low-level flash evaporation after the sandblasting treatment is 62 μm;

[0064] (2) Use cleaning agent to scrub the inner wall, bottom and baffle of the low-level flash chamber, and apply primer and adhesive;

[0065] (3) Lining unvulcanized rubber, pressurized steam vulcanization; the vulcanization process is constant temperature treatment at 0.6Mpa, 150°C for 10h; the thickness of the lining unvulcanized rubber is 4mm, and the unvulcanized rubber is HF-D ;

[0066] The rubber lining is D3 rubber lining;

[0067] 2. Lining bricks: including lining bricks for t...

Embodiment 3

[0078] An anti-corrosion construction method for a low-level flash chamber of a phosphoric acid flash cooling system, including rubber lining and brick lining, specifically comprising the following steps:

[0079] 1. Rubber lining:

[0080] (1) Carry out sandblasting treatment to the inner wall, bottom and baffle plate of the low-level flash evaporation; the roughness of the inner wall, bottom and baffle plate of the low-level flash evaporation after the sandblasting treatment is 80 μm;

[0081] (2) Use cleaning agent to scrub the inner wall, bottom and baffle of the low-level flash chamber, and apply primer and adhesive;

[0082] (3) Lining unvulcanized rubber, pressurized steam vulcanization; the vulcanization process is constant temperature treatment at 0.4Mpa, 130°C for 7h; the thickness of the lining unvulcanized rubber is 4mm, and the unvulcanized rubber is HF-D ;

[0083] The rubber lining is D3 rubber lining;

[0084] 2. Lining bricks: including lining bricks for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com