Preparation method of platinum-precious metal-copper ternary alloy nano hollow cube

A nanocube, ternary alloy technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of reduced catalyst activity, inability to fully utilize energy, and difficult to achieve complete oxidation of ethanol, etc. problems, to achieve the effects of high product yield, excellent electrocatalytic activity and stability, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of cuprous oxide nanocubes

[0032] Take 1mL of 0.05mol / L CuCl 2 Aqueous solution, 5mL 0.05mol / L sodium polyacrylate aqueous solution with a number average molecular weight of 150000, 1.5mL 0.05mol / L ascorbic acid aqueous solution, add 10mL distilled water, stir and mix for 3 minutes, adjust the resulting mixture with 0.5mol / L sodium hydroxide aqueous solution The pH value of the solution was adjusted to 11.5, and stirred at room temperature for 20 minutes to obtain a cuprous oxide nanocube solution.

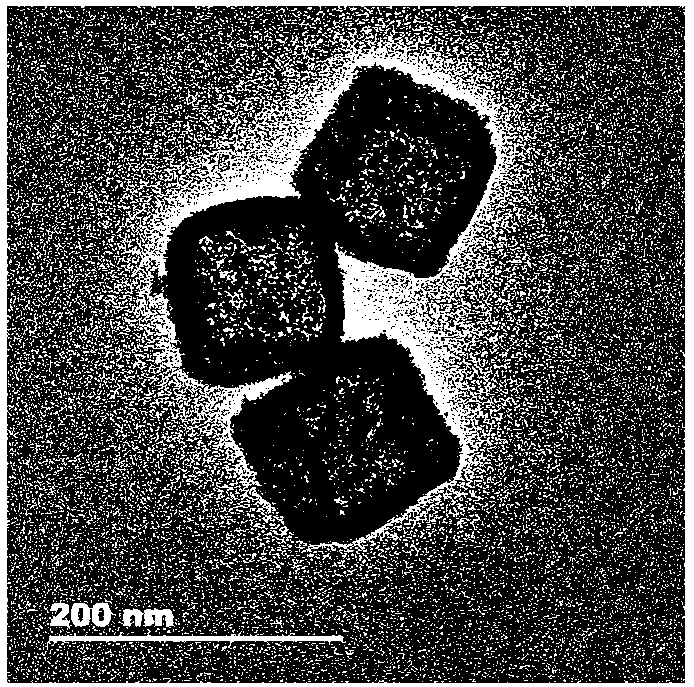

[0033] 2. Preparation of platinum-rhodium-copper ternary alloy nano hollow cubes

[0034] Add 0.285mL 0.025mol / L potassium chloroplatinite aqueous solution and 0.005mL 0.025mol / L rhodium chloride aqueous solution to the cuprous oxide nanocube solution obtained in the above step (1), and use 0.5mol / L sodium hydroxide aqueous solution After adjusting the pH value of the solution to 8, it was reacted at 120° C. for 4 hours. After the reaction, use a high-sp...

Embodiment 2

[0036] In the step 1 of embodiment 1, the cupric chloride used replaces with the cupric sulfate of equimolar, and other steps are identical with embodiment 1, obtain platinum-rhodium-copper ternary alloy nano hollow cube (see image 3 ).

Embodiment 3

[0038] In the step 1 of embodiment 1, 0.05mol / L number-average molecular weight is that the sodium polyacrylate aqueous solution of 150000 is replaced with the sodium polyacrylate aqueous solution of 3000 with equal volume 0.05mol / L number-average molecular weight, and other steps are identical with embodiment 1, Obtain platinum-rhodium-copper ternary alloy nano hollow cube (see Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com