Magnesium iron hydride-graphite composite electrode material and preparation method and application thereof

A composite electrode and composite material technology, which is applied in the field of magnesium-iron hydride-graphite composite electrode materials and its preparation, can solve the problems of hydride activity loss and poor reversibility, and achieve the goals of preventing agglomeration, improving electrical conductivity, and improving reversibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

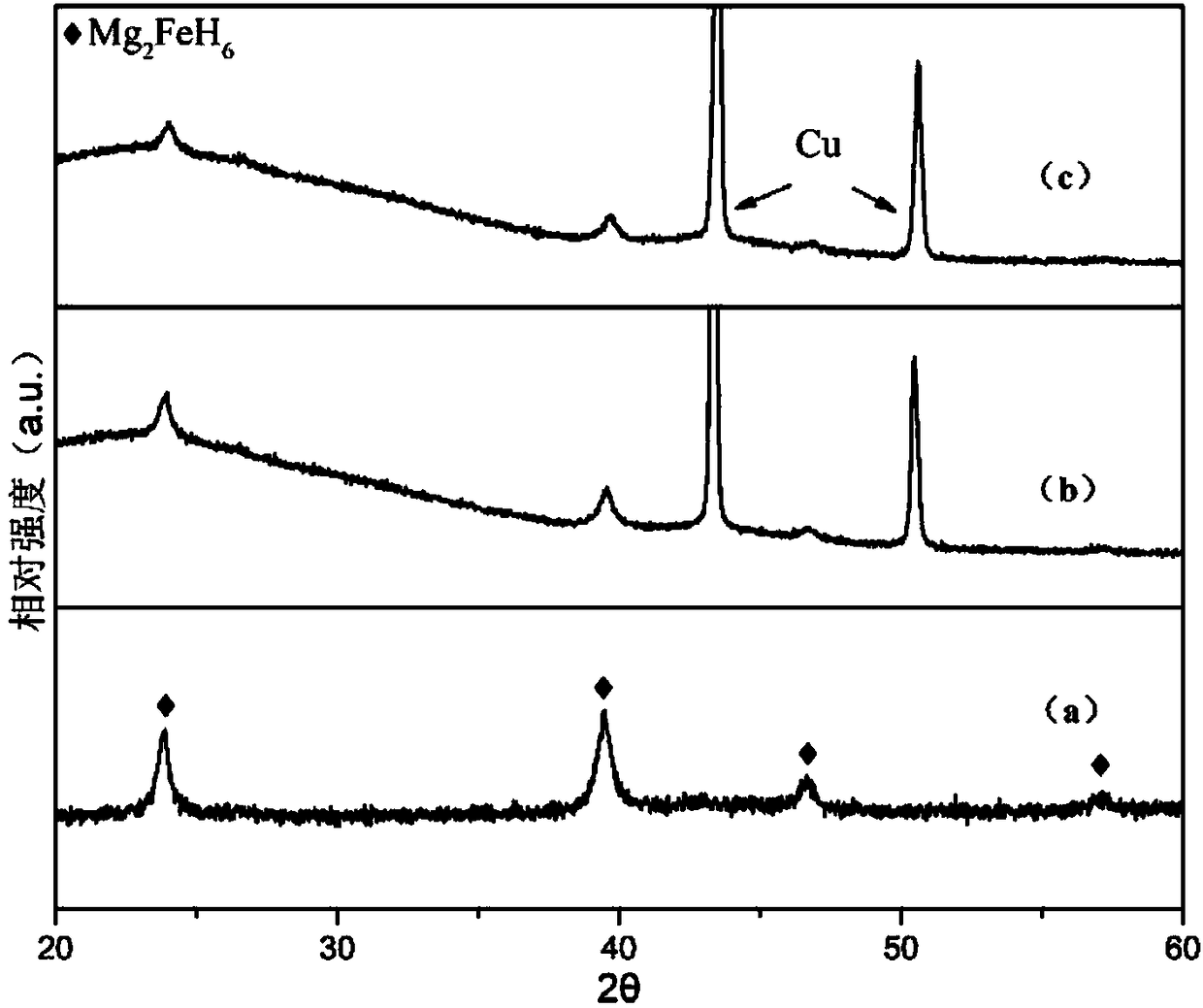

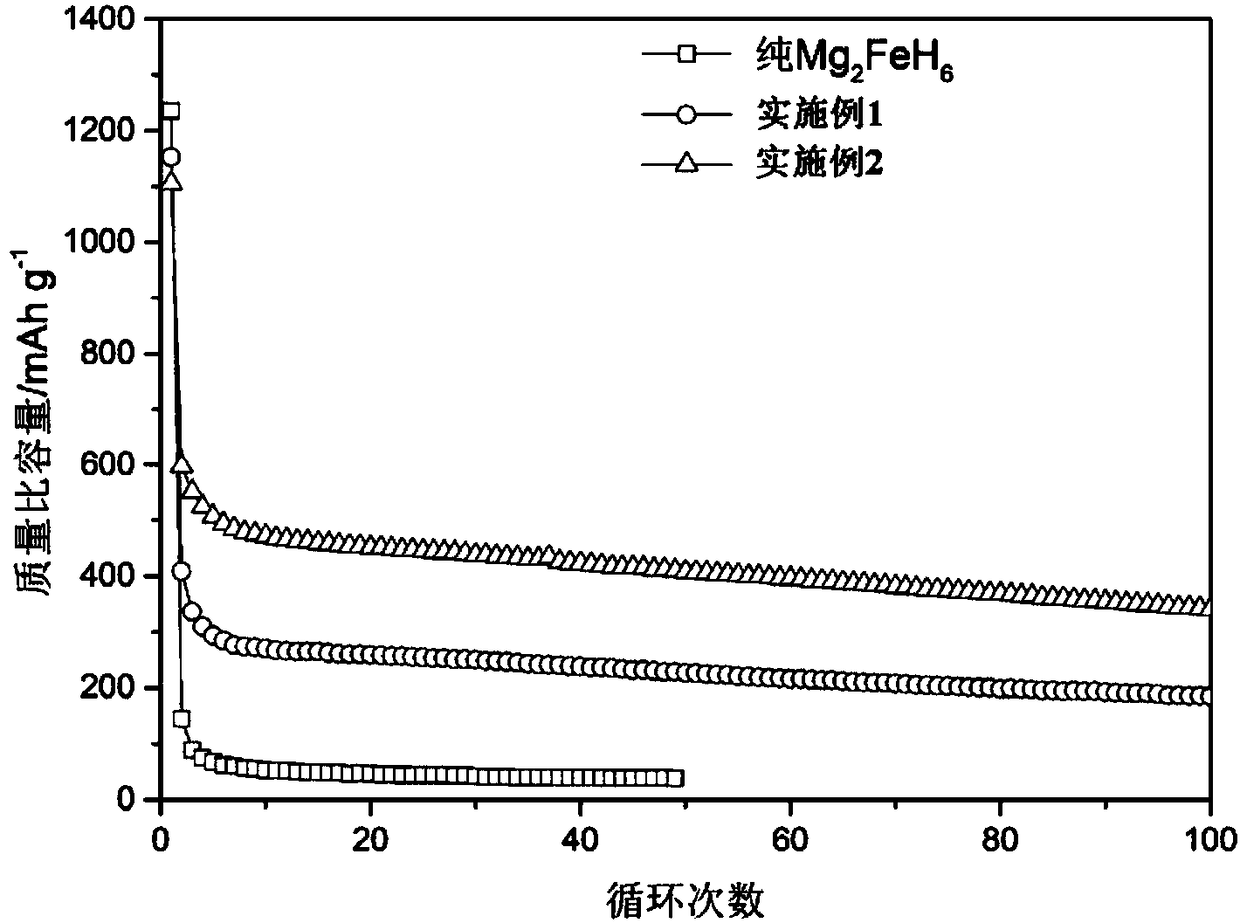

[0039] (1) In the glove box of 0.1MPa argon atmosphere, put magnesium powder and iron powder (purity is not less than 99wt.%) according to the ratio of mass ratio of 2.2:1 into the ball mill jar and put the ball mill jar on high energy In the planetary ball mill (QM-3SP4), 6 MPa hydrogen gas is introduced, the ball-to-material ratio is 40:1, the ball milling speed is 500 rpm, and the ball milling is carried out alternately for 15 minutes and 15 minutes, and the ball milling is carried out in a hydrogen atmosphere for 20 hours.

[0040] (2) After the ball milling is completed, take the powder in an argon atmosphere glove box, transfer the powder to a high-pressure reactor, feed 9MPa hydrogen, heat to 450°C at a heating rate of 5K / min, and keep it for 20h to obtain Mg 2 FeH 6 powder.

[0041] (3) Mg obtained by step (2) 2 FeH 6The powder and graphite are put into a ball milling jar with a mass ratio of 9:1, and the ball milling jar is placed in a high-energy planetary ball mi...

Embodiment 2

[0049] (1) In the glove box of 0.1MPa argon atmosphere, put magnesium powder and iron powder (purity is not less than 99wt.%) according to the ratio of mass ratio of 2.2:1 into the ball mill jar and put the ball mill jar on high energy In the planetary ball mill (QM-3SP4), 6 MPa hydrogen gas is introduced, the ball-to-material ratio is 40:1, the ball milling speed is 500 rpm, and the ball milling is carried out alternately for 15 minutes and 15 minutes, and the ball milling is carried out in a hydrogen atmosphere for 20 hours.

[0050] (2) After the ball milling is completed, take the powder in an argon atmosphere glove box, transfer the powder to a high-pressure reactor, feed 9MPa hydrogen, heat to 450°C at a heating rate of 5K / min, and keep it for 20h to obtain Mg 2 FeH 6 powder.

[0051] (3) Mg obtained by step (2) 2 FeH 6 The powder and graphite are put into a ball milling jar with a mass ratio of 8.5:1.5, and the ball milling jar is placed in a high-energy planetary ba...

Embodiment 3

[0058] (1) In the glove box of 0.1MPa argon atmosphere, put magnesium powder and iron powder (purity is not less than 99wt.%) according to the ratio of mass ratio of 2.2:1 into the ball mill jar and put the ball mill jar on high energy In the planetary ball mill (QM-3SP4), 6 MPa hydrogen gas is introduced, the ball-to-material ratio is 40:1, the ball milling speed is 500 rpm, and the ball milling is carried out alternately for 15 minutes and 15 minutes, and the ball milling is carried out in a hydrogen atmosphere for 20 hours.

[0059] (2) After the ball milling is completed, take the powder in an argon atmosphere glove box, transfer the powder to a high-pressure reactor, feed 9MPa hydrogen, heat to 450°C at a heating rate of 5K / min, and keep it for 20h to obtain Mg 2 FeH 6 powder.

[0060] (3) Mg obtained by step (2) 2 FeH 6 The powder and graphite are put into a ball milling jar with a mass ratio of 8:2, and the ball milling jar is placed in a high-energy planetary ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com