A kind of preparation method of modified superabsorbent resin internal curing agent

A technology of superabsorbent resin and curing agent, which is applied in the field of modified superabsorbent resin internal curing agent, which can solve the problems of reducing the liquid absorption rate of superabsorbent resin, slow water absorption, and reducing water diffusion channels, etc., to achieve free control of water absorption and increase Effects of water retention and strength, strong dispersion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

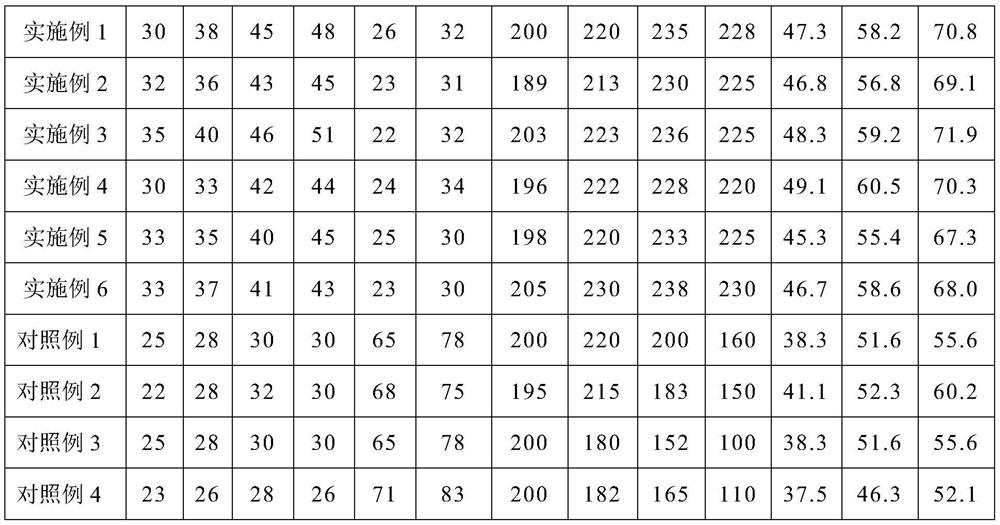

Examples

Embodiment 1

[0028] (1) Dissolve 1.5 mol of dodecyl primary amine in 2.8 mol of diethylene glycol dipropylene glycol monobutyl ether, then add 1 mol of octadecatrienoic acid and stir at 45°C for 1 hour to obtain unsaturated fatty primary amines monomer; then 100 parts of methallyl alcohol polyoxyethylene ether (molecular weight 800), 80 parts of unsaturated fatty primary amine monomer, 80 parts of hydroxyethyl acrylate were dissolved in 740 parts of water, in 1 part of hydrogen peroxide 1. Under the action of 5 parts of ascorbic acid, carry out free radical polymerization and stir at 30°C for 5 hours to obtain a modified superabsorbent resin;

[0029] (2) Dissolve 100 parts of sodium silicate in 100 parts of aluminum-modified silica sol (10nm) dispersion, add 1 part of 2-methacrylic acid chromium tetrachloride and stir for 5 hours under high shear conditions to obtain modified silicon Sodium acid.

[0030] (3) Add 3 parts of modified sodium silicate to 100 parts of modified superabsorbent...

Embodiment 2

[0032] (1) Dissolve 2 mol of tetradecyl primary amine in 1.5 mol of diethylene glycol monobutyl ether, then add 1 mol of docosahexaenoic acid and stir at 63°C for 1.5 hours to obtain unsaturated fatty primary amine monomer ; Then 100 parts of isobutyl alcohol polyoxyethylene ether (molecular weight 8000), 100 parts of unsaturated fatty primary amine monomers, 50 parts, hydroxypropyl acrylate are dissolved in 1000 parts of water, in 1.5 parts of ammonium persulfate, 8 parts of suspension Carry out free radical polymerization reaction under the action of white block and stir at 50°C for 1 hour to obtain modified superabsorbent resin;

[0033] (2) Dissolve 100 parts of sodium silicate in 150 parts of aluminum-modified silica sol (5nm) dispersion, add 5 parts of chromium tetrachloride 2-methacrylate under high shear conditions and stir for 8 hours to obtain modified silicon Sodium acid;

[0034](3) Add 7 parts of modified sodium silicate to 100 parts of modified superabsorbent re...

Embodiment 3

[0036] (1) Dissolve 1.6 mol of hexadecyl primary amine in 2 mol of dipropylene glycol diethylene glycol monobutyl ether, then add 1 mol of eicosapentaenoic acid and stir at 50°C for 1 hour to obtain monounsaturated fatty primary amine body; then 100 parts of isopentenol polyoxyethylene ether (molecular weight 5000), 120 parts of unsaturated fatty primary amine monomers, 60 parts of hydroxyethyl methacrylate were dissolved in 840 parts of water, in 2 parts of sodium persulfate 1. Carry out radical polymerization under the action of 6 parts of sodium sulfite and stir at 40°C for 3 hours to obtain a modified superabsorbent resin;

[0037] (2) Dissolve 100 parts of sodium silicate in 120 parts of aluminum-modified silica sol (10nm) dispersion, add 6 parts of chromium tetrachloride 2-methacrylic acid under high shear conditions and stir for 10 hours to obtain modified silicon Sodium acid;

[0038] (3) Add 5 parts of modified sodium silicate to 100 parts of modified superabsorbent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com