Preparation method of extruded magnesium oxide tube

A magnesia, extrusion type technology, applied in the field of metallurgy, can solve the problems of long operation and high production cost of magnesia tube, and achieve the effect of reducing production links, good compactness and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

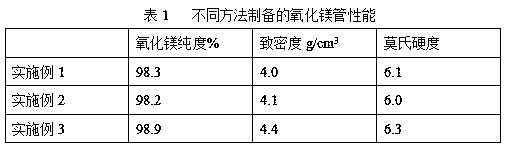

Examples

preparation example Construction

[0015] The invention provides a method for preparing magnesium oxide tubes by dry pressing, comprising the following steps: a. performing magnetic separation on magnesium oxide powder through an electromagnetic magnetic separator; b. ball milling to a certain fineness after magnetic separation; c. , Stir with high-viscosity cellulose and magnesium oxide powder, and stir it into a dough; d, put the mixed magnesium oxide paste into the barrel, and extrude it through a mold; e, the magnesium oxide after extrusion The tube is calcined at high temperature to become a finished product.

[0016] Wherein, the viscosity of the high-viscosity cellulose in step c is 300,000 viscosity.

[0017] Wherein, the high-viscosity cellulose in step c is methyl cellulose.

[0018] Among them, the airflow granulated magnesium oxide particles are 80-100 mesh.

[0019] In the present invention, in order to reduce the impurity in magnesium oxide, first adopt electromagnetic magnetic separator to carr...

Embodiment 1

[0025] Example 1 Using the method of the present invention to prepare magnesium oxide tubes

[0026] The specific operation steps are as follows:

[0027] a, magnesium oxide powder is carried out magnetic separation through electromagnetic magnetic separator, after magnetic separation, ball milling becomes 350 mesh powder; Magnetic field intensity is 0.5T during described magnetic separation;

[0028] B. Put the mixed paste of methyl cellulose and magnesium oxide powder into an extrusion molding machine, and extrude to obtain a semi-finished product;

[0029] c. Put the semi-finished product obtained in step b into a sintering furnace for sintering, and obtain the magnesium oxide tube 1 after sintering; the sintering temperature is 1200-1300° C., and the sintering time is 40 minutes.

Embodiment 2

[0030] Example 2 Using the method of the present invention to prepare magnesium oxide tubes

[0031] The specific operation steps are as follows:

[0032] a, magnesium oxide powder is carried out magnetic separation through electromagnetic magnetic separator, and after magnetic separation, ball mills into 400 mesh powder; Magnetic field strength is 2T during described magnetic separation;

[0033] B. Put the mixed paste of methyl cellulose and magnesium oxide powder into an extrusion molding machine, and extrude to obtain a semi-finished product;

[0034] c. Put the semi-finished product obtained in step b into a sintering furnace for sintering, and obtain a magnesium oxide tube after sintering; the sintering temperature is 1200-1300° C., and the sintering time is 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com