Thickened type glyphosate and glufosinate compound aqueous auxiliary agent and preparation technology thereof

A technology of glyphosate and glufosinate, applied in herbicides, algaecides, insecticides, biocides, etc., can solve the problems such as the inability of output to meet market demand, the long way to go for research, and the reduction of drug costs. , to achieve a significant synergistic effect, reduce the number of applications, and control the waste of the original drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

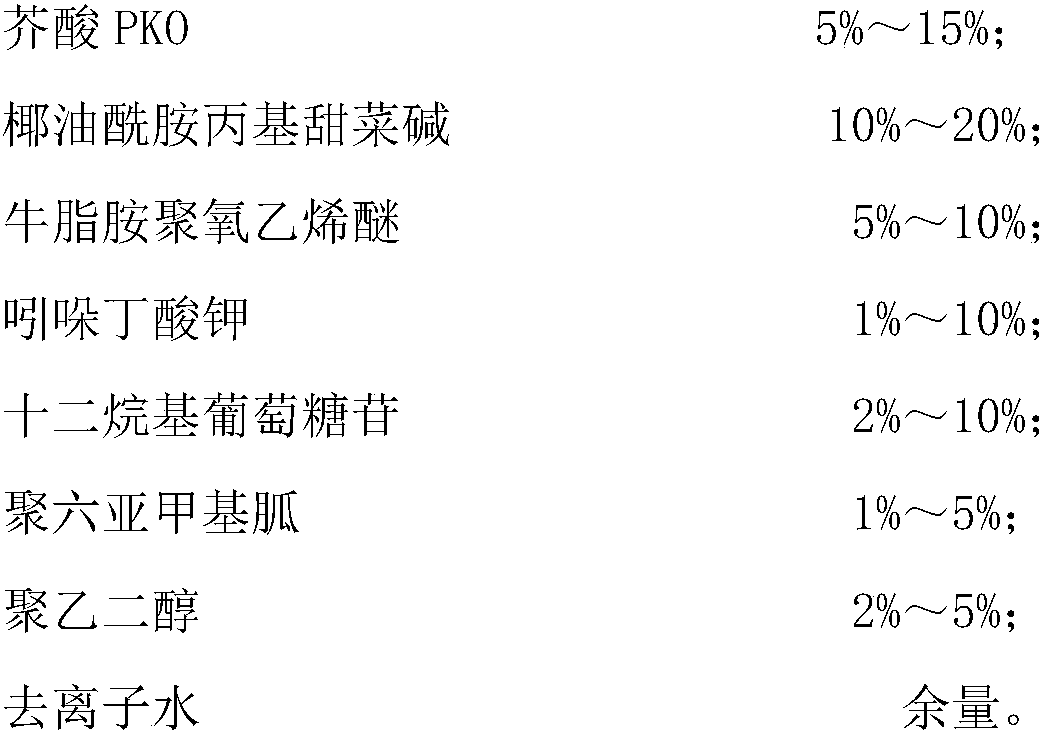

Method used

Image

Examples

Embodiment 1

[0030] Take the following weight materials: mix the measured 10% erucic acid PKO, erucamide propyl dimethyl tertiary amine, and 15% cocamidopropyl betaine into the reactor, stir well and add 8% Lauryl glucoside, stirred at 50°C for 5 minutes, then added 2% polyhexamethylene guanidine and water, stirred and dissolved, added quantitative 5% tallow amine polyoxyethylene ether, 5% indole butyl Potassium acid potassium, stirring and dispersing for 15 minutes, and finally adding 2% polyethylene glycol to the product, stirring and mixing evenly, sending it into a colloid mill, and grinding for 10 minutes to obtain thickened glyphosate and glufosinate-ammonium compound water agent agent.

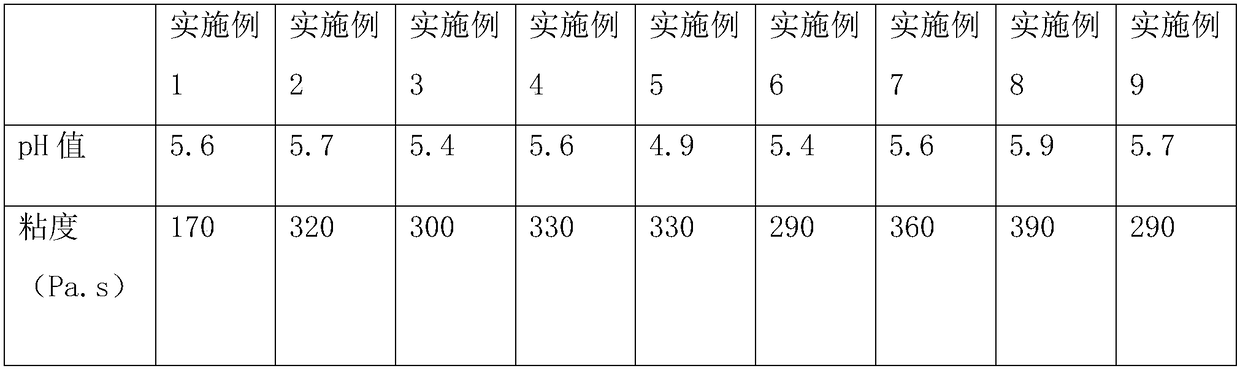

[0031] Viscosity determination of the prepared thickening glyphosate and glufosinate-ammonium compound water agent special additives:

[0032] Instrument: NDJ-79 rotary viscometer (Jiangsu Tongjun Technology Instrument Co., Ltd.);

[0033] Test temperature: room temperature;

[0034] Rotor: No. 1...

Embodiment 2

[0045] Mix the measured 12% erucic acid PKO, erucamide propyl dimethyl tertiary amine, and 18% cocamidopropyl betaine into the reaction kettle, stir well and then add the weighed 7% dodecyl glucoside , stirred at 50°C for 5 minutes, then added 3% polyhexamethyleneguanidine and water, stirred and dissolved, added quantitative 6% tallow amine polyoxyethylene ether, 7% potassium indole butyrate, stirred and dispersed for 15 After 10 minutes, finally add 3% polyethylene glycol to the product, stir and mix evenly, send it to a colloid mill, and grind for 10 minutes to obtain a special additive for thickening glyphosate and glufosinate-ammonium compound water.

[0046] According to the test method of Example 1, the thickened glyphosate and glufosinate-ammonium compound water agent special additive prepared by this formula has a pH value of 5.7, a viscosity of 320mPa.s, a surface tension of 16.9mN / m, and a foam height of 18mL.

Embodiment 3

[0048] Mix the metered 8% erucic acid PKO, erucamide propyl dimethyl tertiary amine, and 20% cocamidopropyl betaine into the reaction kettle, stir well and add the weighed 6% lauryl glucoside , stirred at 50°C for 5 minutes, then added 2% polyhexamethyleneguanidine and water, stirred and dissolved, added quantitative 8% tallow amine polyoxyethylene ether, 6% potassium indole butyrate, stirred and dispersed for 15 Finally, add 3% polyethylene glycol to the product, stir and mix evenly, send it to a colloid mill, and grind for 10 minutes to obtain a special additive for thickening glyphosate and glufosinate-ammonium compound water.

[0049]According to the test method of Example 1, the thickened glyphosate and glufosinate-ammonium compound water agent special additive prepared by this formula has a pH value of 5.4, a viscosity of 300mPa.s, a surface tension of 15.5mN / m, and a foam height of 19mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com