Spring-tooth retractable intertillage soil loosening and weeding unit

A telescopic, spring-tooth technology, applied in shovels, plows, agricultural machinery and implements, etc., can solve the problems of unsatisfactory effect, low weeding rate and high rate of damage to seedlings, and achieve novel structural design, low rate of damage to seedlings, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

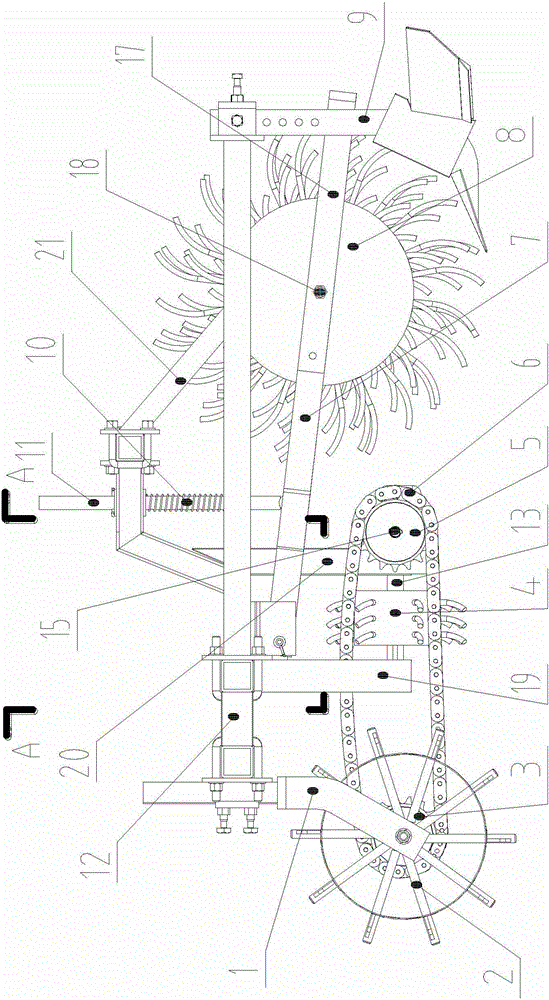

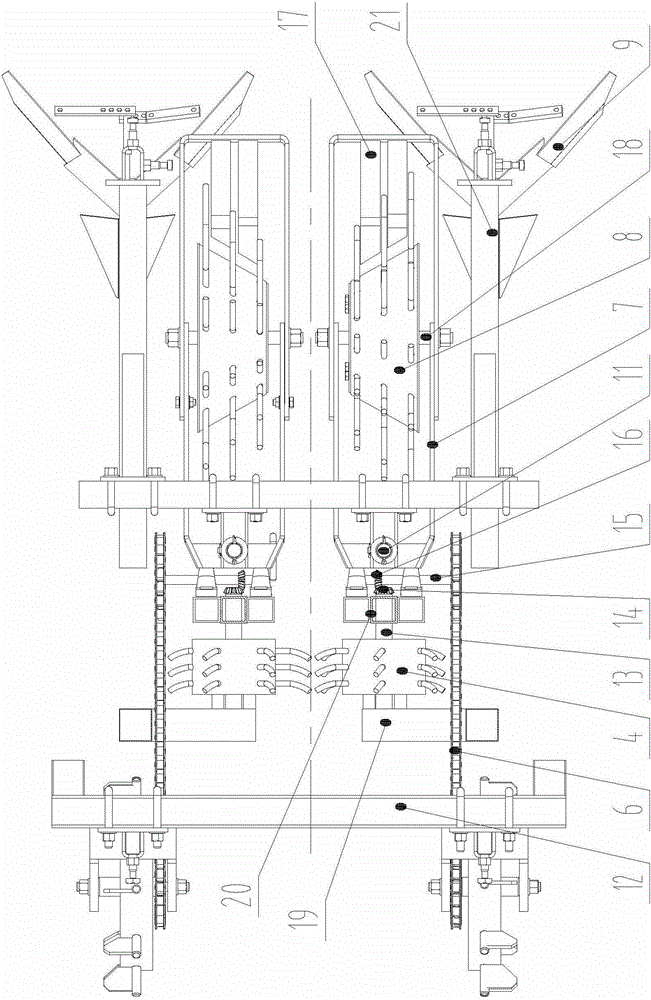

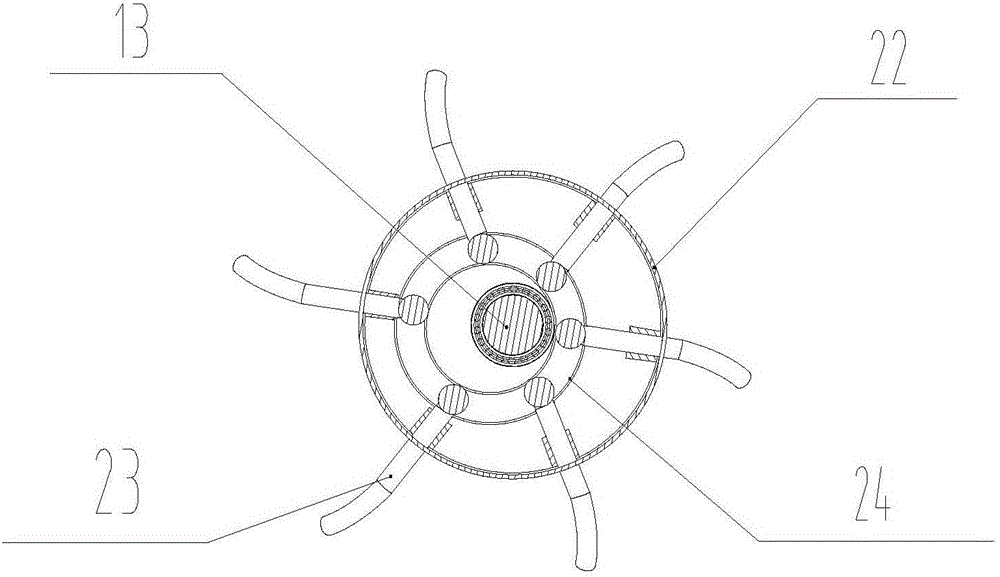

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A spring-tooth telescopic cultivator loosening and weeding single body, on the left and right sides of the front end of the single frame 12, the driving ground wheel 2 is respectively installed through the ground wheel frame 1, and on the left and right sides of the single frame 12 1. A front hanger 19 and a rear hanger 20 are respectively installed in sequence from front to back at the rear parts of the driving ground wheels 2 on the left and right sides, and the front hanger 19 and the rear hanger 20 on the left and right sides pass through the column Shaped drum drive shaft 13 rotatable hangs and installs eccentric slideways respectively to drive elastic tooth telescopic loosening and weeding cylindrical drum 4, and the cylindrical drum driving shaft 13 axis line of both sides is parallel to the longitudinal center line of seedling row, and both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com