Forming method and device of sintered Nd-Fe-B radiation magnetic ring

A molding method and NdFeB technology, which is applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of increasing the production cost of sintered NdFeB magnetic rings, uneven density, and low magnetic field strength. To achieve the effect of convenient processing, uniform magnetic ring density and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

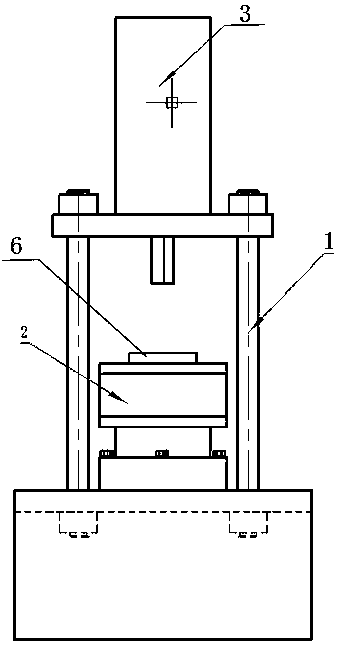

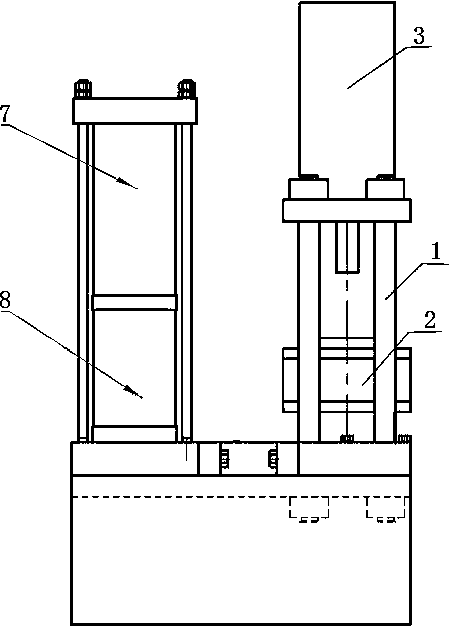

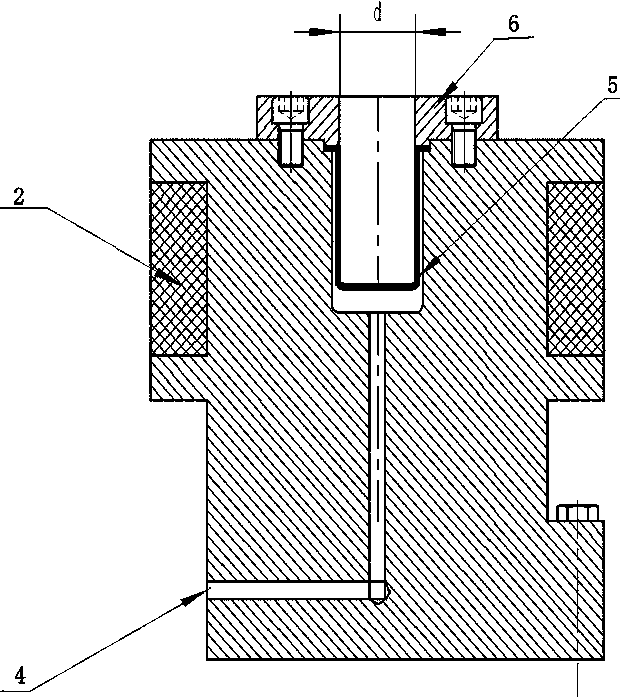

[0018] The forming method of the sintered NdFeB radiation magnetic ring includes the following steps: 1) Firstly, the magnetic powder is preformed with a magnetic field orientation to obtain a preformed magnetic ring blank; the selection of the preforming pressure should not only meet the requirements of forming, but also fix the orientation of the magnetic powder Come down, leave the compressed density space for the magnetic ring blank in the subsequent secondary compression step; the height of the magnetic ring blank meets the required orientation magnetic field strength as the criterion, and make the integer multiple of its height as possible as The actual required height of the formed magnetic ring; 2) According to the actual required height of the magnetic ring, several pre-formed magnetic ring blanks obtained in step 1) are threaded on a metal mandrel with clearance fit to obtain a secondary compression Formed magnetic ring combination; 3) Apply isostatic pressure to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com