Carbonized bacterial cellulose/carbon nanotube film material and preparation method thereof

A technology of bacterial cellulose and carbon nanotube film, which is applied in the field of carbonized bacterial cellulose/carbon nanotube film material and its preparation, can solve the problems of bacterial cellulose destruction, environmental pollution, and easy surface peeling of carbon nanotubes. Achieve the effect of increasing the conductivity and increasing the injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

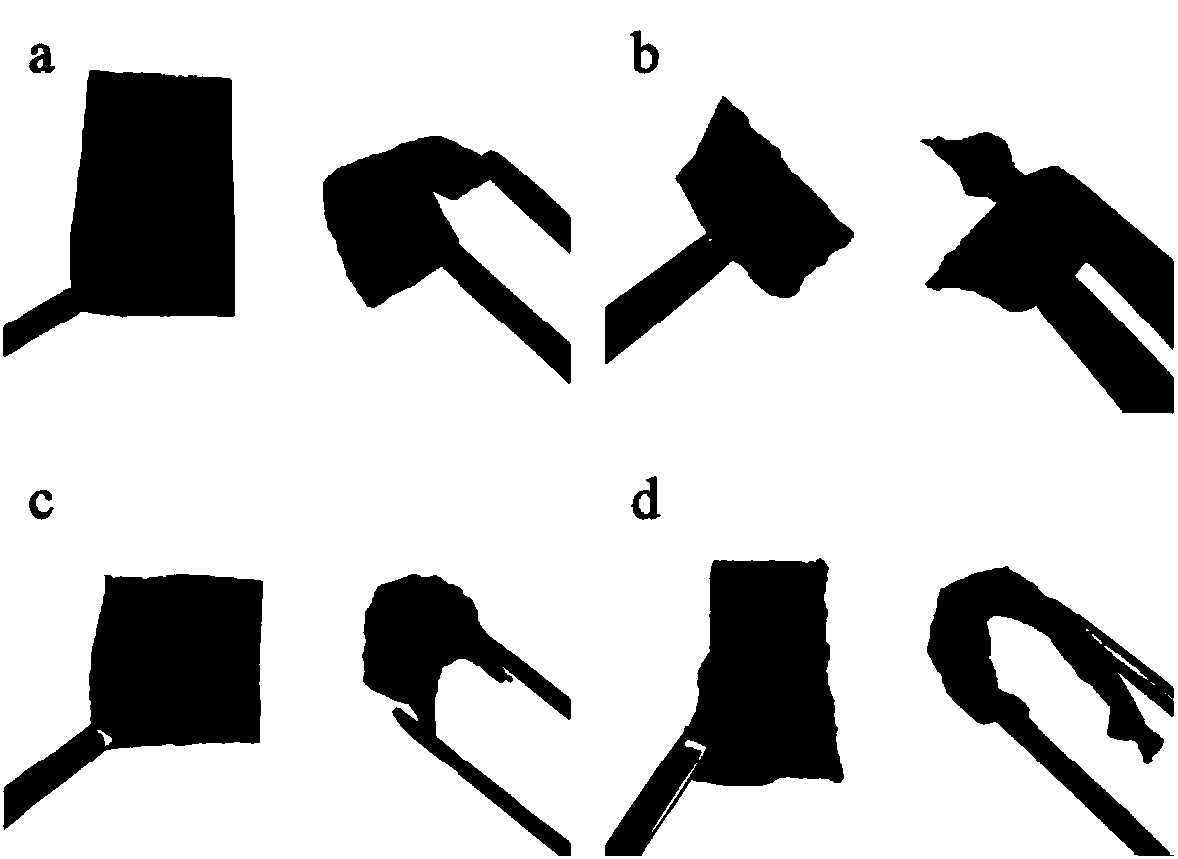

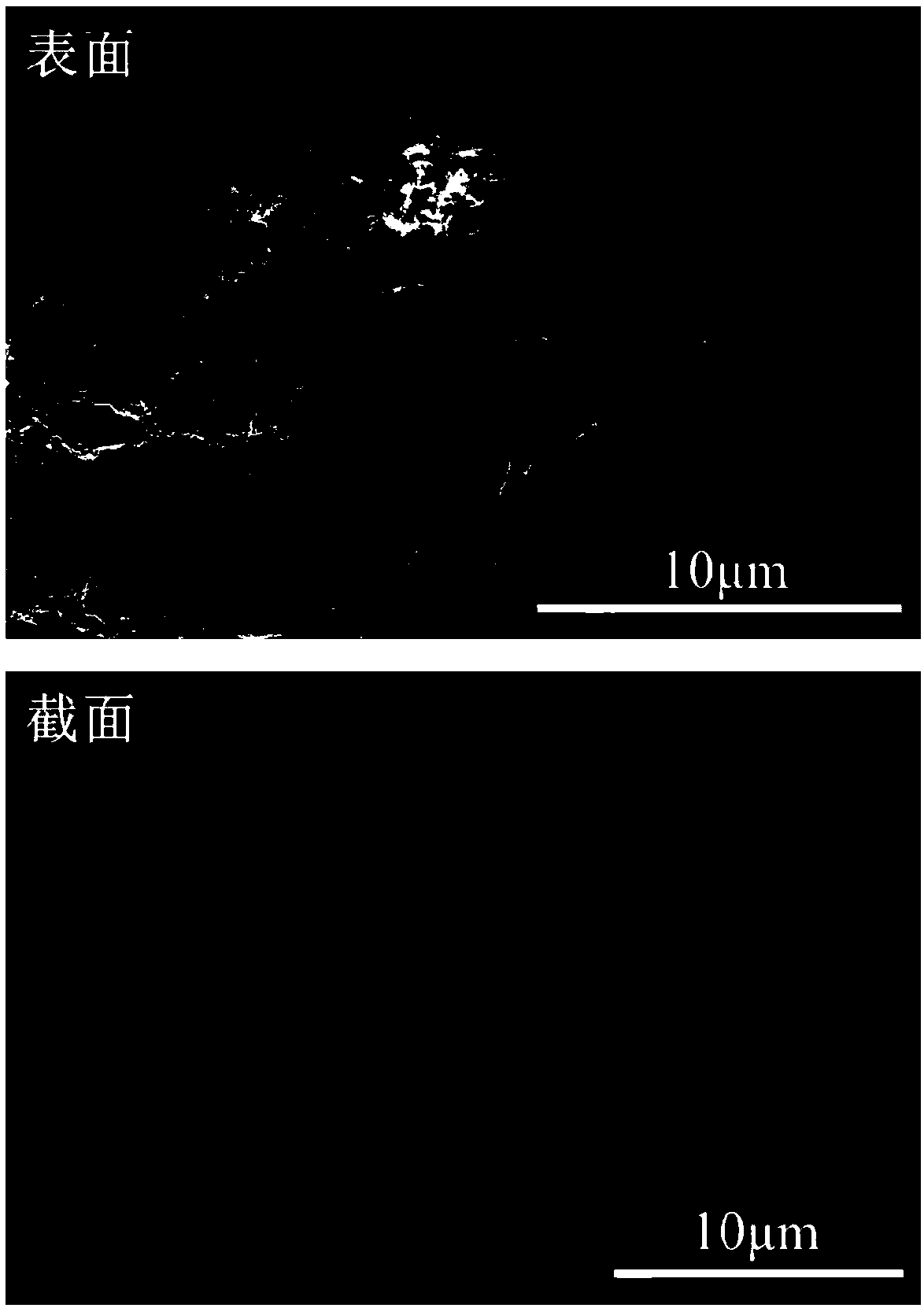

[0029] A preparation method of carbonized bacterial cellulose / carbon nanotube film: disperse carboxylated multi-walled carbon nanotubes with a diameter of 7 to 15 nm and a length of 5 to 20 μm in the surfactant cetyltrimethylammonium bromide 0.3wt % aqueous solution, obtain a concentration of 0.05wt% carboxylated multi-walled carbon nanotube aqueous solution, and then use the ultrasonic cell breaker to break and disperse, the power is 600W, the ultrasonic time is 10min, and finally the highly stable carboxylated multi-walled carbon nanotubes are prepared Nanodispersion. Use conventional cellulose filter paper to suck out the moisture of bacterial cellulose hydrogel, then soak it in highly stable carboxylated multi-walled carbon nanotube nano-dispersion at room temperature, and fully absorb the multi-walled carbon nanotube dispersion to achieve multi-walled carbon nanotube dispersion. Uniform distribution of walled carbon nanotubes in bacterial cellulose hydrogels. Utilize con...

Embodiment 2

[0031]A preparation method of carbonized bacterial cellulose / carbon nanotube film: disperse carboxylated multi-walled carbon nanotubes with a diameter of 7 to 15 nm and a length of 5 to 20 μm in the surfactant cetyltrimethylammonium bromide 0.3wt % aqueous solution, obtain a concentration of 0.05wt% carboxylated multi-walled carbon nanotube aqueous solution, and then use the ultrasonic cell breaker to break and disperse, the power is 600W, the ultrasonic time is 10min, and finally the highly stable carboxylated multi-walled carbon nanotubes are prepared Nanodispersion. Use conventional cellulose filter paper to suck out the moisture of bacterial cellulose hydrogel, then soak it in highly stable carboxylated multi-walled carbon nanotube nano-dispersion at room temperature, and fully absorb the multi-walled carbon nanotube dispersion to achieve multi-walled carbon nanotube dispersion. Uniform distribution of walled carbon nanotubes in bacterial cellulose hydrogels. Utilize conv...

Embodiment 3

[0033] A preparation method of carbonized bacterial cellulose / carbon nanotube film: disperse carboxylated multi-walled carbon nanotubes with a diameter of 30 to 50 nm and a length of 10 to 20 μm in 0.3 wt% of the surfactant sodium dodecylbenzenesulfonate In the aqueous solution, obtain a carboxylated multi-walled carbon nanotube aqueous solution with a concentration of 0.05wt%, and then use an ultrasonic cell breaker to break and disperse it. The power is 400W, and the ultrasonic time is 40min. liquid. Use conventional cellulose filter paper to suck out the moisture of bacterial cellulose hydrogel, then soak it in highly stable carboxylated multi-walled carbon nanotube nano-dispersion at room temperature, and fully absorb the multi-walled carbon nanotube dispersion to achieve multi-walled carbon nanotube dispersion. Uniform distribution of walled carbon nanotubes in bacterial cellulose hydrogels. Utilize conventional cellulose filter paper to absorb water to the hydrogel of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com