Method for coupling preparing ethylene glycol by photocatalyzing formaldehyde and methanol

A technology of ethylene glycol and photocatalyst, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of low activity and selectivity of methanol and formaldehyde, and achieve high atomic economy and reaction conditions. Gentle, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

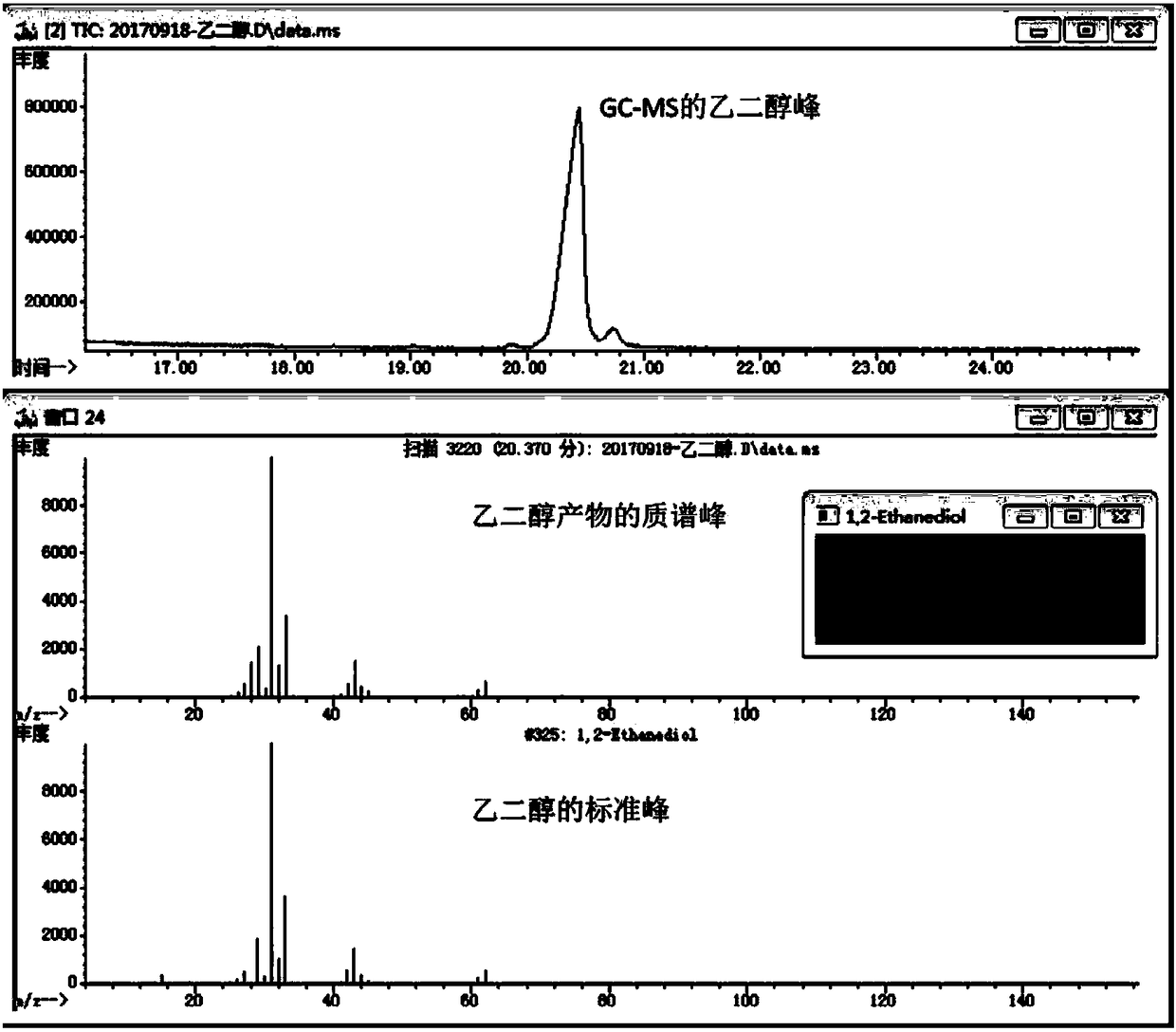

Image

Examples

Embodiment 1

[0035] Titanium dioxide (Degussa P25) was uniformly dispersed in 25 ml of deionized water. Then 6mL H 2 PtCl 6 (0.01g / mL) solution was added dropwise to the above slurry at a constant speed. The above solution was sonicated in an ultrasonic machine for 5 minutes, and then stirred at room temperature (25° C.) for one hour. The above samples were dried in a vacuum oven at 60°C. After drying, the samples were taken out for grinding. Take 1.5 g of the above catalyst precursor and reduce it at 300° C. for 3 hours under a hydrogen (99.99%) atmosphere, wherein the hydrogen flow rate is 100 mL / min. After the reduction, argon gas (99.99%) was introduced to cool down to room temperature, and then the catalyst was taken out, the noble metal Pt-supported titanium dioxide, the Pt loading was 0.44wt%, and the average particle diameter of Pt particles was 4nm. Disperse 5mg of solid catalyst in 2mL of methanol, then add 1mL of standard formaldehyde solution (formaldehyde concentration is...

Embodiment 2

[0037] Titanium dioxide (Degussa P25) was uniformly dispersed in 25 ml of deionized water. Then 10mlPdCl 2 solution (0.007g / mL) was added dropwise to the above slurry at a constant speed. The above solution was sonicated in an ultrasonic machine for 5 minutes, and then stirred at room temperature (25° C.) for one hour. The above samples were dried in a vacuum oven at 60°C. After drying, the samples were taken out for grinding. 1.5 g of the above catalyst precursor was taken and reduced at 300° C. for 3 hours under a hydrogen (99.99%) atmosphere, wherein the hydrogen flow rate was 100 mL / min. After the reduction, argon gas (99.99%) was introduced to cool down to room temperature, and then the catalyst was taken out, the noble metal Pd-supported titanium dioxide, the Pd loading was 0.48wt%, and the average particle size of Pd particles was 4nm. Disperse 5mg of solid catalyst in 2mL of methanol, then add 1mL of standard formaldehyde solution (formaldehyde concentration is 10m...

Embodiment 3

[0039] Titanium dioxide (Degussa P25) was uniformly dispersed in 25 ml of deionized water. Then 12mlRuCl 3 solution (0.008g / mL) was added dropwise to the above slurry at a constant speed. The above solution was sonicated in an ultrasonic machine for 5 minutes, and then stirred at room temperature (25° C.) for one hour. The above samples were dried in a vacuum oven at 60°C. After drying, the samples were taken out for grinding. Take 1.5 g of the above catalyst precursor and reduce it at 300° C. for 3 hours under a hydrogen (99.99%) atmosphere, wherein the hydrogen flow rate is 100 mL / min. After the reduction, argon gas (99.99%) was introduced to cool down to room temperature, and then the catalyst was taken out, the noble metal Ru supported titanium dioxide, the Ru loading was 0.48wt%, and the average particle diameter of Ru particles was 2nm. Disperse 5mg of solid catalyst in 2mL of methanol, then add 1mL of standard formaldehyde solution (formaldehyde concentration is 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com