Automobile steel plate trimming device

An automotive steel plate, trimming technology, used in grinding/polishing safety devices, grinding slides, machine tools suitable for grinding workpiece edges, etc. , steel plate quality decline and other problems, to ensure the effect of process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

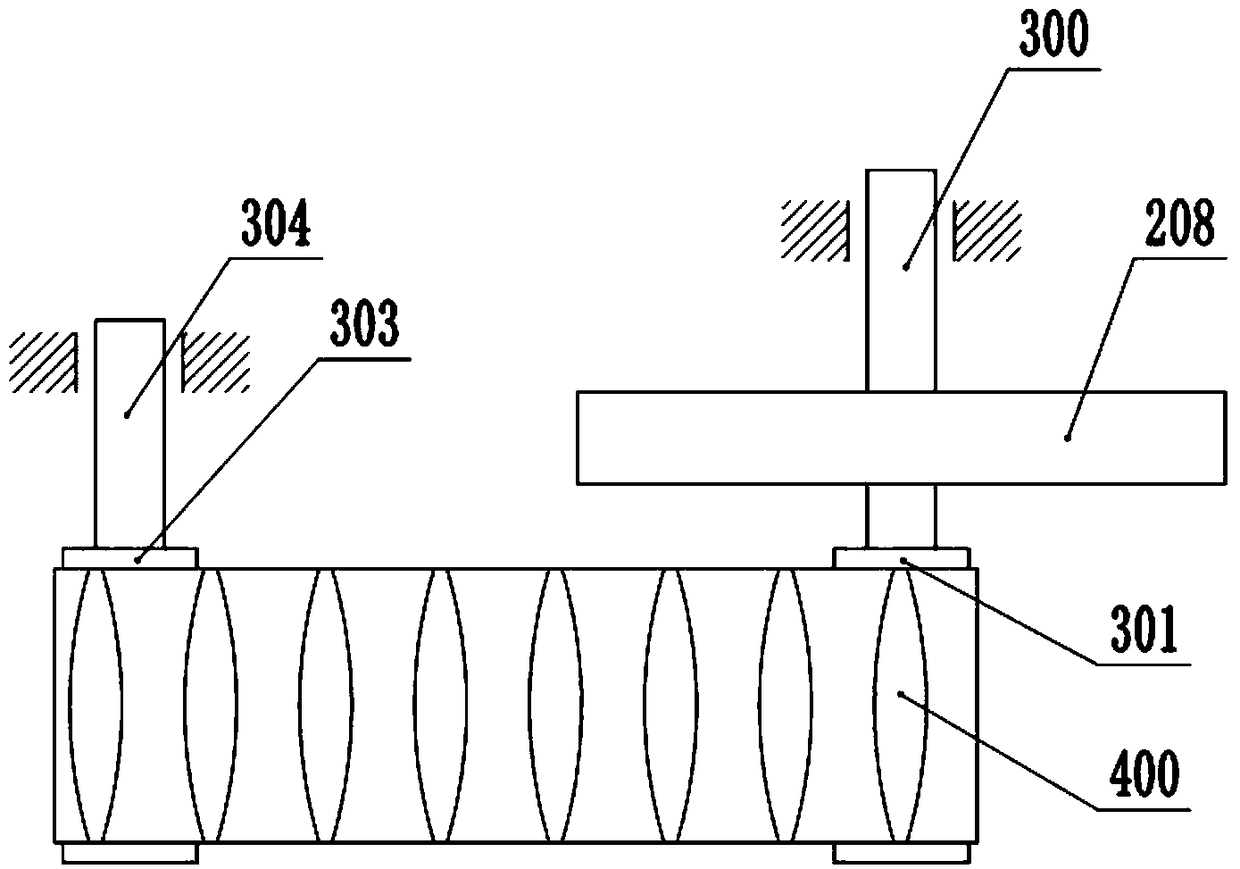

[0034] The reference signs in the accompanying drawings include: steel plate 1, telescopic shaft 100, support shaft 101, transmission shaft 102, telescopic cavity 103, positioning hole 104, through hole 105, positioning pin 106, support platform 107, suction cup 108, first Rotating shaft 200, ball bearing 201, bearing seat 202, grinding wheel 203, driving pulley 204, driven pulley 205, belt 206, driving gear 207, driven gear 208, second rotating shaft 300, driving roller 301, conveyor belt 302, Tension roller 303, tension shaft 304, air bag 400, head 401, tail 402, liquid inlet 403, liquid outlet pipe 404, movable block 405, adsorption net 406, collection tray 500, collection tank 501, liquid outlet valve 502 , The liquid guide bucket 503.

[0035] Such as figure 1 Shown is an embodiment of the present invention, and an automobile steel plate trimming device is announced. This devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com