Electrified composite membrane with extracellular matrix electrical topology characteristics, and preparation method thereof

A technology of topological features and composite membranes, applied in medical science, tissue regeneration, bone implants, etc., can solve the problems of poor matching of natural extracellular matrix characteristics and limited repair effect of materials, and achieve good electrical compatibility, Good inductive bone repair performance and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take 9ml of glacial acetic acid and 1.340g of acetylacetone, mix and stir for 5min, add 1.703g of barium acetate, stir for 1h, add 2.266g of tetrabutyl titanate, stir for 15min, then add 0.45g of polyvinylpyrrolidone (PVP), stir 3h;

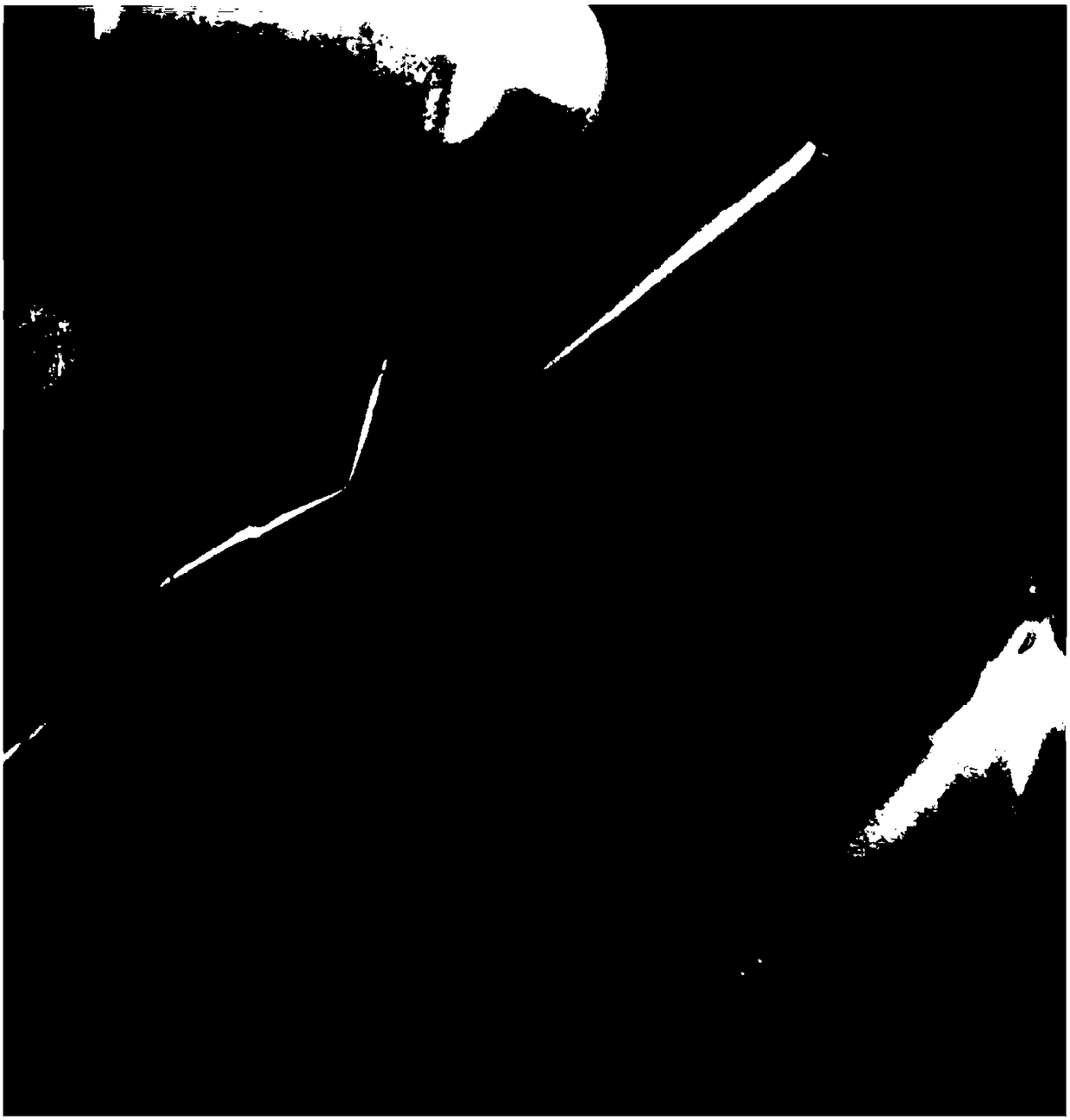

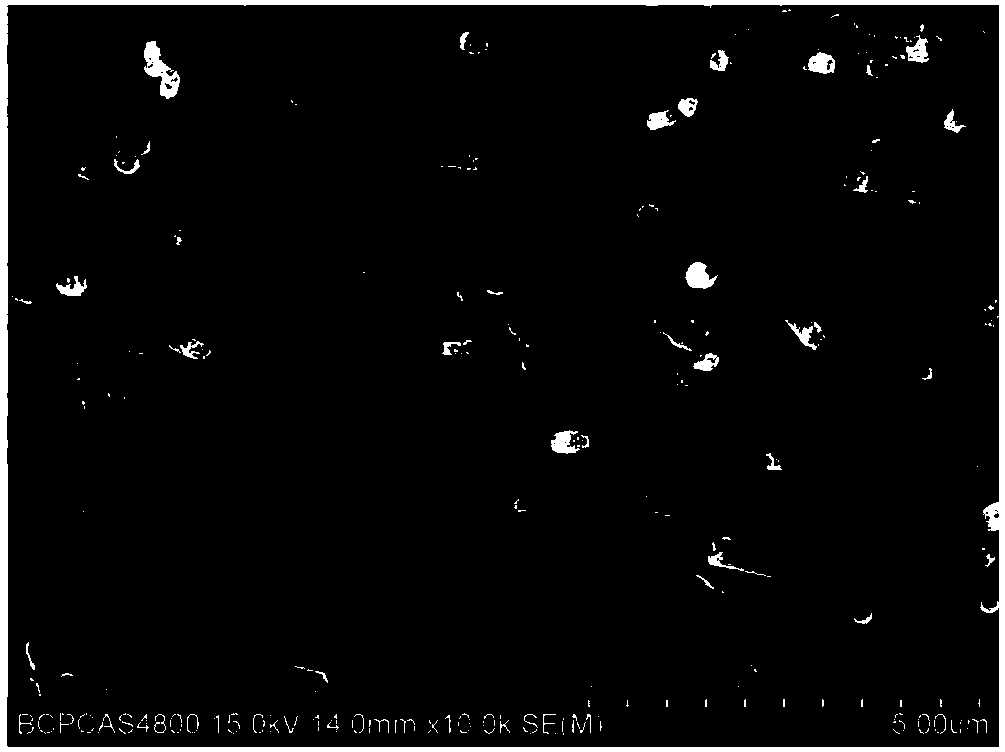

[0040] (2) inject the mixed solution obtained in step (1) into the syringe, and use electrospinning technology under the condition of voltage 14kV to obtain barium titanate nanofibers with a diameter of 200nm;

[0041] (3) Put the barium titanate nanofibers obtained in step (2) into 0.01mol / L dopamine aqueous solution, heat and stir in a 60-degree water bath for 12 hours, then ultrasonically oscillate for 5 minutes, and obtain titanic acid with an aspect ratio of 12 after centrifugal drying Barium nanofiber filler;

[0042] (4) Take an appropriate amount of the barium titanate nanofiber filler obtained in step (3) and disperse it in 3mL of organic solvent DMF by ultrasonic oscillation, and use ultrasonic oscillation combined with stir...

Embodiment 2

[0053] (1) Take 9ml of glacial acetic acid and 1.340g of acetylacetone, mix and stir for 5min, add 1.703g of barium acetate, stir for 1h, add 2.266g of tetrabutyl titanate, stir for 15min, then add 0.45g of polyvinylpyrrolidone (PVP), stir 3h;

[0054] (2) inject the mixed solution obtained in step (1) into the syringe, and use electrospinning technology under the condition of voltage 16kV to obtain barium titanate nanofibers with a diameter of 300nm;

[0055] (3) Put the barium titanate nanofibers obtained in step (2) into 0.05mol / L dopamine aqueous solution, heat and stir in a 60-degree water bath for 12 hours, then ultrasonically vibrate for 10 minutes, and obtain barium titanate with an aspect ratio of 8 after centrifugal drying nanofiber filler;

[0056] (4) Take an appropriate amount of the barium titanate nanofiber filler obtained in step (3) and disperse it in 3mL of organic solvent DMF by ultrasonic oscillation, and use ultrasonic oscillation combined with stirring f...

Embodiment 3

[0067] (1) Take 9ml of glacial acetic acid and 1.340g of acetylacetone, mix and stir for 5min, add 1.703g of barium acetate, stir for 1h, add 2.266g of tetrabutyl titanate, stir for 15min, then add 0.45g of polyvinylpyrrolidone (PVP), stir 3h;

[0068] (2) inject the mixed solution obtained in step (1) into the syringe, and use electrospinning technology under the condition of voltage 12kV to obtain barium titanate nanofibers with a diameter of 400nm;

[0069] (3) Put the barium titanate nanofibers obtained in step (2) into 0.08mol / L dopamine aqueous solution, heat and stir in a 60-degree water bath for 12 hours, then ultrasonically vibrate for 1 minute, and obtain barium titanate with an aspect ratio of 20 after centrifugal drying nanofiber filler;

[0070] (4) Take an appropriate amount of the barium titanate nanofiber filler obtained in step (3) and disperse it in 3mL of organic solvent DMF by ultrasonic oscillation, and use ultrasonic oscillation combined with stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com