Chitosan nano particle with carbon dioxide and acid responsiveness and preparation method of aqueous dispersion of chitosan nano particle

A chitosan nano and carbon dioxide technology, applied in the field of drug carrier and adsorption, can solve the problem of no stimulus response, and achieve the effect of functional enhancement, mild conditions and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

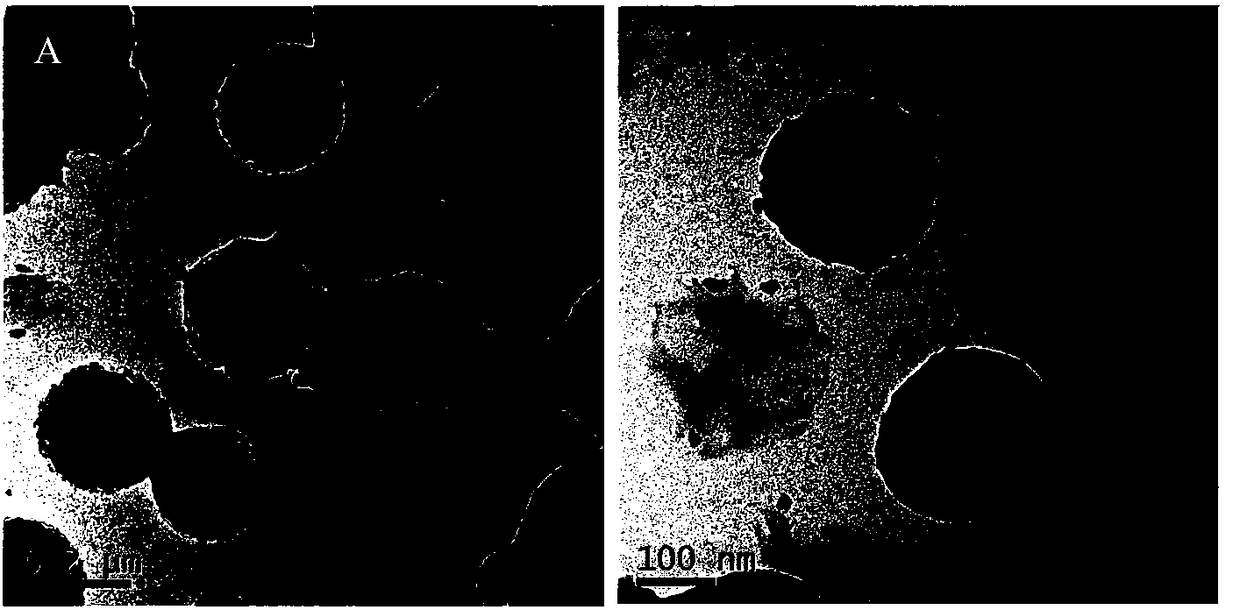

Image

Examples

Embodiment 1

[0032] 1) Weigh 4.00g (2mmol) polyethylene glycol monomethyl ether (M n =2000) into a 100mL flask, add 50mLCH 2 Cl 2 And stir to dissolve, then add 1.50g 4-formylbenzoic acid, 1.92g EDC·HCl, 0.48g 4-dimethylaminopyridine (DMAP) and 2.8mL N-methylmorpholine; After stirring at room temperature for 24 hours, the reaction The solution was concentrated by rotary evaporation; the solid was precipitated in isopropanol, and after standing overnight, it was suction filtered, and the filter cake was washed three times with isopropanol; Glycol monomethyl ether (i.e. mPEG-CHO, M n =2000).

[0033] 2) Weigh 2.3g carboxymethyl chitosan and add it to a 100mL flask, then add 0.05g NaOH and 40mL distilled water, stir and dissolve to obtain carboxymethyl chitosan aqueous solution; add 1.5g mPEG-CHO (M n =2000) room temperature reaction for 24 hours, then get 8mL reaction solution, dropwise add the CaCl of 1.5mg / mL 2 2 mL of the solution was added dropwise and stirred rapidly, and after sta...

Embodiment 2

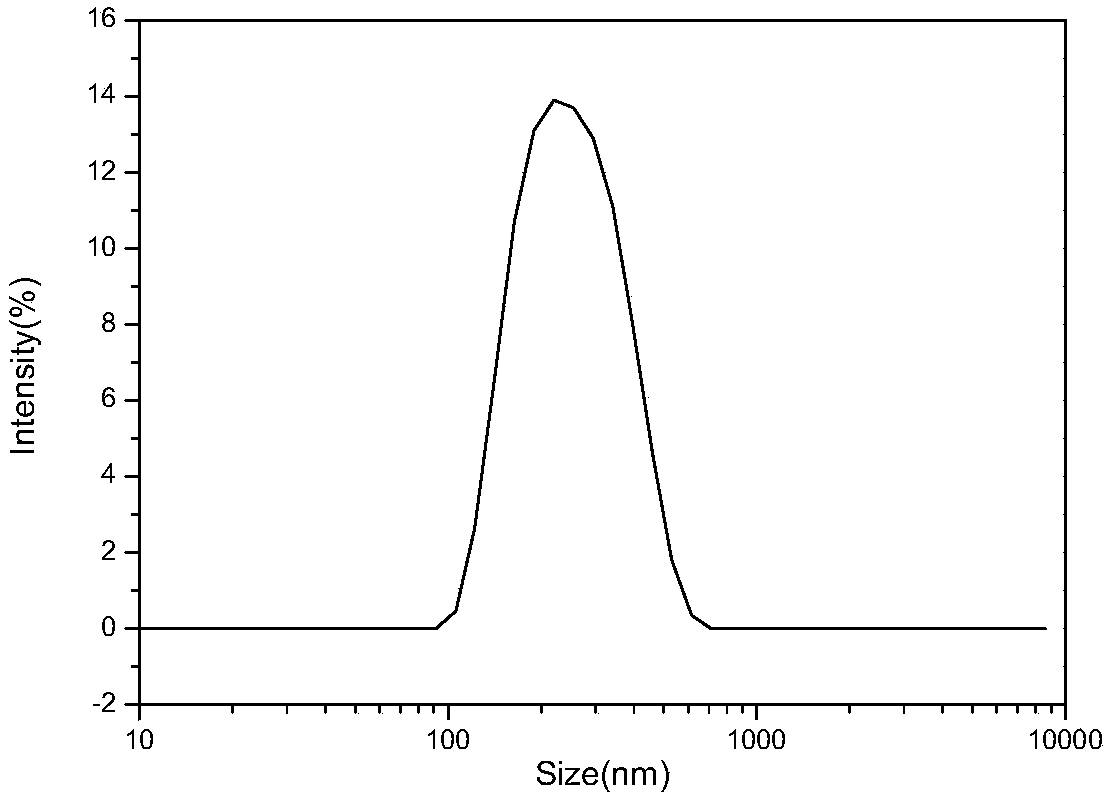

[0036] Different from Example 1, the NaOH added is changed to the sodium bicarbonate of the same mass, and the CaCl added dropwise is changed. 2 The concentration of the solution, the CaCl 2 The solution was increased to 1.8mg / mL, and the constant pressure dropping funnel was used for dropping at the same time, and it took 8.5 minutes to finish dropping, and finally prepared chitosan nanoparticles, which were characterized by a laser particle size analyzer. The Z average particle size was 237nm, polydisperse Coefficient PDI = 1.24.

Embodiment 3

[0038] 1) 16.0g (4mmol) polyethylene glycol monomethyl ether (mPEG, M n =4000) was dissolved in 50mL of dichloromethane, then added 3.0g p-formylbenzoic acid, 4.46g dicyclohexylcarbodiimide (DCC), 0.96g 4-dimethylaminopyridine (DMAP), and reacted at room temperature for 24 hours Afterwards, the reaction solution was concentrated, precipitated in isopropanol at 0° C., and the precipitate was collected by filtration. The filter cake was washed with isopropanol, and vacuum-dried at room temperature for 12 hours to obtain a white powder form of benzaldehyde-based polyethylene glycol monomethyl ether (mPEG -CHO, M n =4000).

[0039] 2) Take a 100mL flask, add 3.0g carboxymethyl chitosan and 40mL PBS buffer solution (pH=7.4), stir and dissolve to obtain carboxymethyl chitosan aqueous solution; then add 4.0g mPEG-CHO prepared in step 1) (M n =4000), feed nitrogen as a protective atmosphere, react at room temperature for 24 hours, then take 8mL of the reaction solution, and dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com