Clean smelting device and technology of low-grade scrap copper

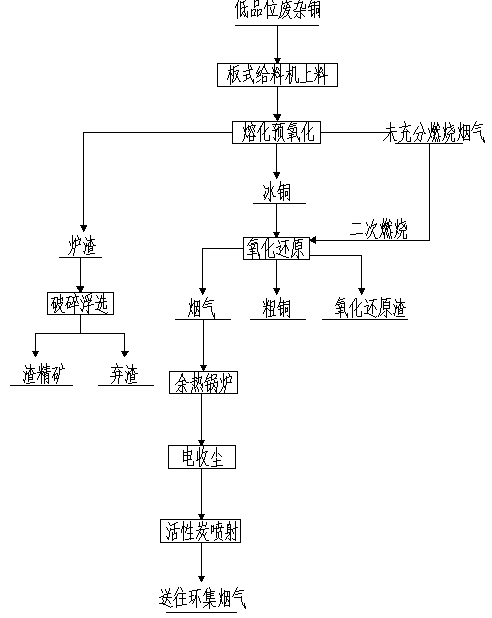

A smelting device and waste miscellaneous copper technology, which is applied in the field of low-grade waste miscellaneous copper clean smelting equipment, can solve the problems of energy saving, environmental protection, and unreasonable economy, so as to avoid the generation of dioxin, Improve environmental protection conditions and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

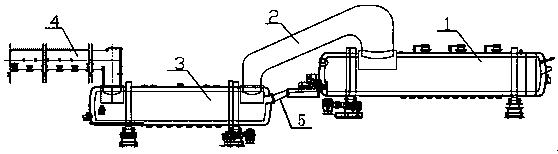

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

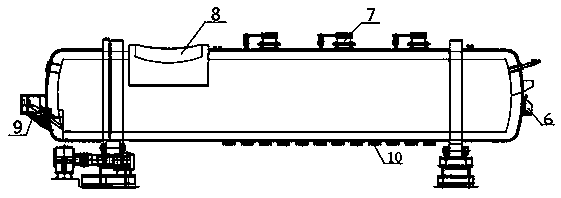

[0023] A low-grade scrap copper clean smelting device and its process, the device includes a melting furnace 1, a redox furnace 3, a flue 2, and a secondary combustion chamber 4, the melting furnace 1 and redox furnace 3 are rotatable Horizontal cylindrical furnace body, the flue port 8 of the melting furnace 1 is connected to the flue gas inlet 16 of the redox furnace 3 through the flue 2, the flue gas outlet 13 of the redox furnace 3 is connected to the secondary combustion chamber 4, and the melting furnace The copper discharge port A9 of 1 is connected to the feed port 17 of the redox furnace 3 through the matte guide tube 5; a number of natural gas burners 18 are provided on the side of the flue gas inlet 16 of the redox furnace 3; the top of the redox furnace 3 is provided with Two flue openings, one is the flue gas inlet 16 of the melting furnace 1 at one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com