Phase-changing heat absorption expansive flame-retardant fireproof water-based paint and preparation method thereof

A water-based coating, intumescent flame-retardant technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of no flame-retardant fire-proof effect, low fire-proof efficiency, etc., to reduce fire losses, reduce temperature and fire-proof effect significantly, and hinder the release of combustible gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

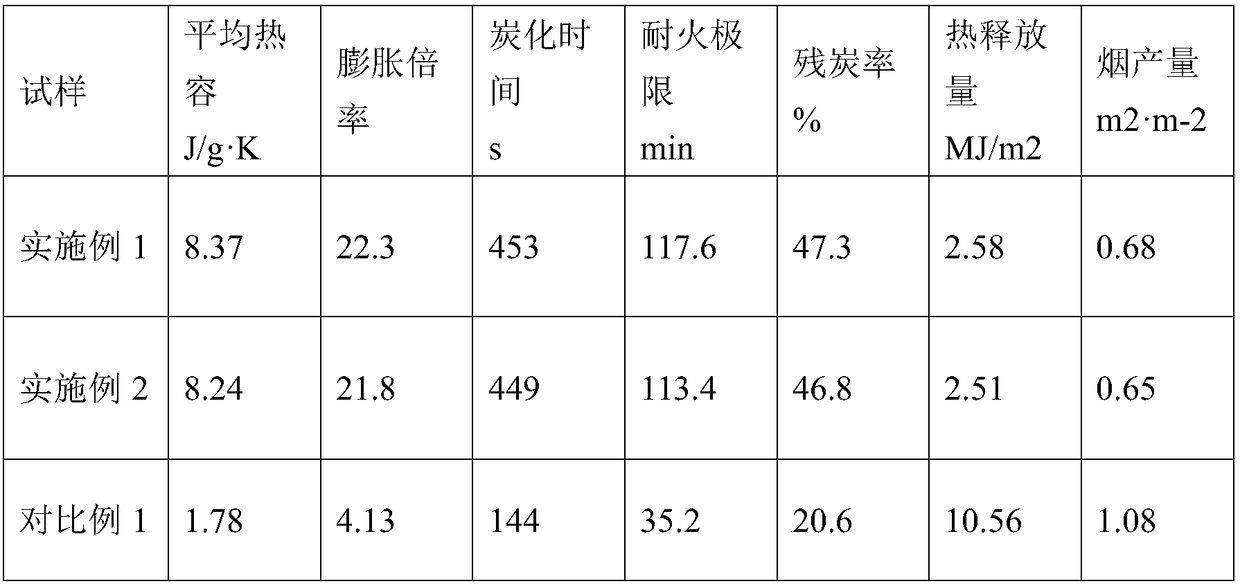

Examples

Embodiment 1

[0044] A kind of intumescent flame-retardant fireproof water-based coating of phase change endothermic of the present invention, its preparation method comprises the steps:

[0045] (1) Preparation of polyethylene glycol phase change self-crosslinking acrylate film-forming emulsion: 300kg of water and 50kg of acetone are added to the reactor, and 500kg of polyethylene glycol-4000 is added (4000 is the degree of polymerization of polyethylene glycol) , stir, heat up to 60°C, stir to dissolve; then add 0.25kg of catalyst dodecylbenzenesulfonic acid (p-toluenesulfonic acid) and 5kg of acrylic acid, continue heating to 110°C, stir for 6 hours; add 3kg of acrylic acid, Heating to 140° C., continuing to stir and react for 2 hours, and the reaction is completed to obtain a polyethylene glycol phase-change self-crosslinking acrylate film-forming emulsion;

[0046] (2) Preparation of galactose intumescent flame retardant system: with 100kg ammonium polyphosphate APP (n>1000) (acid sour...

Embodiment 2

[0051] A kind of intumescent flame-retardant fireproof water-based coating of phase change endothermic of the present invention, its preparation method comprises the steps:

[0052] (1) Preparation of polyethylene glycol phase change self-crosslinking acrylate film-forming emulsion: 300kg of water and 50kg of acetone are added to the reactor, and 450kg of polyethylene glycol-4000 is added (4000 is the degree of polymerization of polyethylene glycol) , stir, heat up to 60°C, stir to dissolve; then add 0.25kg of catalyst dodecylbenzenesulfonic acid (p-toluenesulfonic acid) and 5kg of acrylic acid, continue heating to 110°C, stir for 6 hours; add 3kg of acrylic acid, Heating to 140° C., continuing to stir and react for 2 hours, and the reaction is completed to obtain a polyethylene glycol phase-change self-crosslinking acrylate film-forming emulsion;

[0053] (2) Preparation of galactose intumescent flame retardant system: with 100kg ammonium polyphosphate APP (n>1000) (acid sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com