Ternary system resin and preparation method thereof, and composite material and preparation method thereof

A ternary system and resin technology, applied in the field of polymer physics, polymer material modification, and polymer chemistry, can solve the problems of low mechanical properties and achieve improved mechanical properties, improved mechanical properties, excellent heat resistance and mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In Example 1, Example 2 and Example 3, the cyanate ester raw material was purchased from Yangzhou Tianqi New Material Co., Ltd., bisphenol A type cyanate ester monomer was selected, the product model was CE01MO, and bisphenol E type cyanate was selected Ester monomer, the product model is CE09MO.

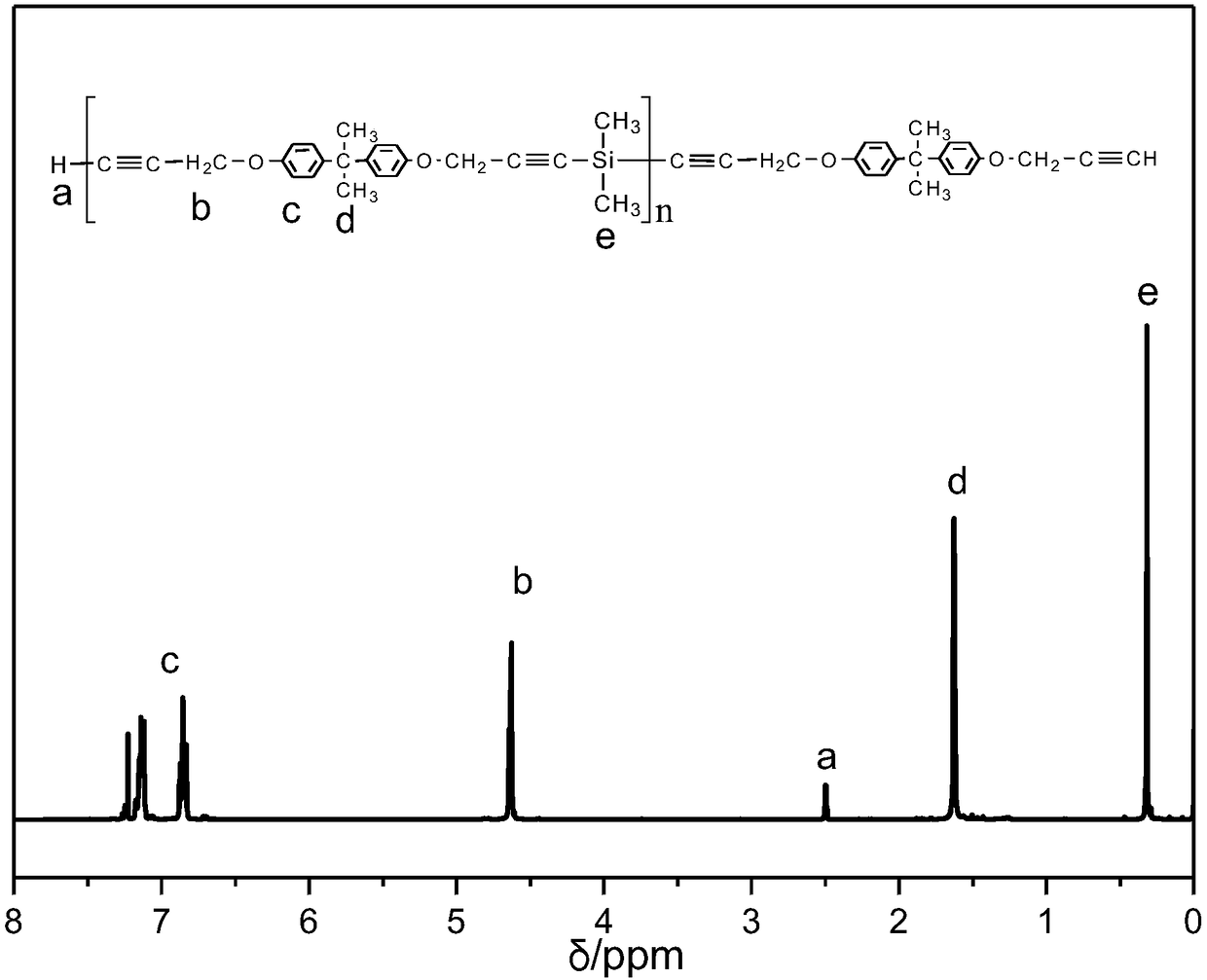

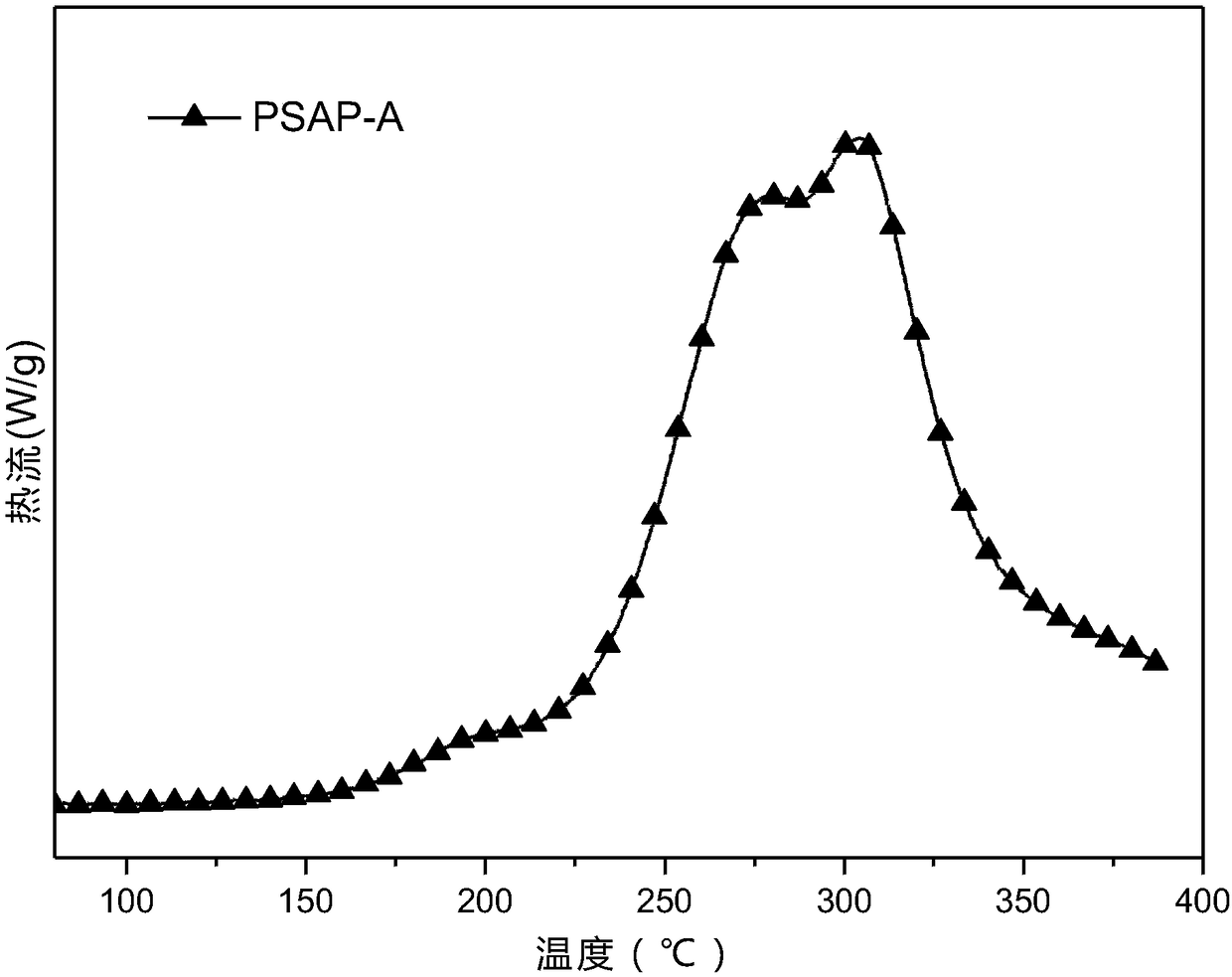

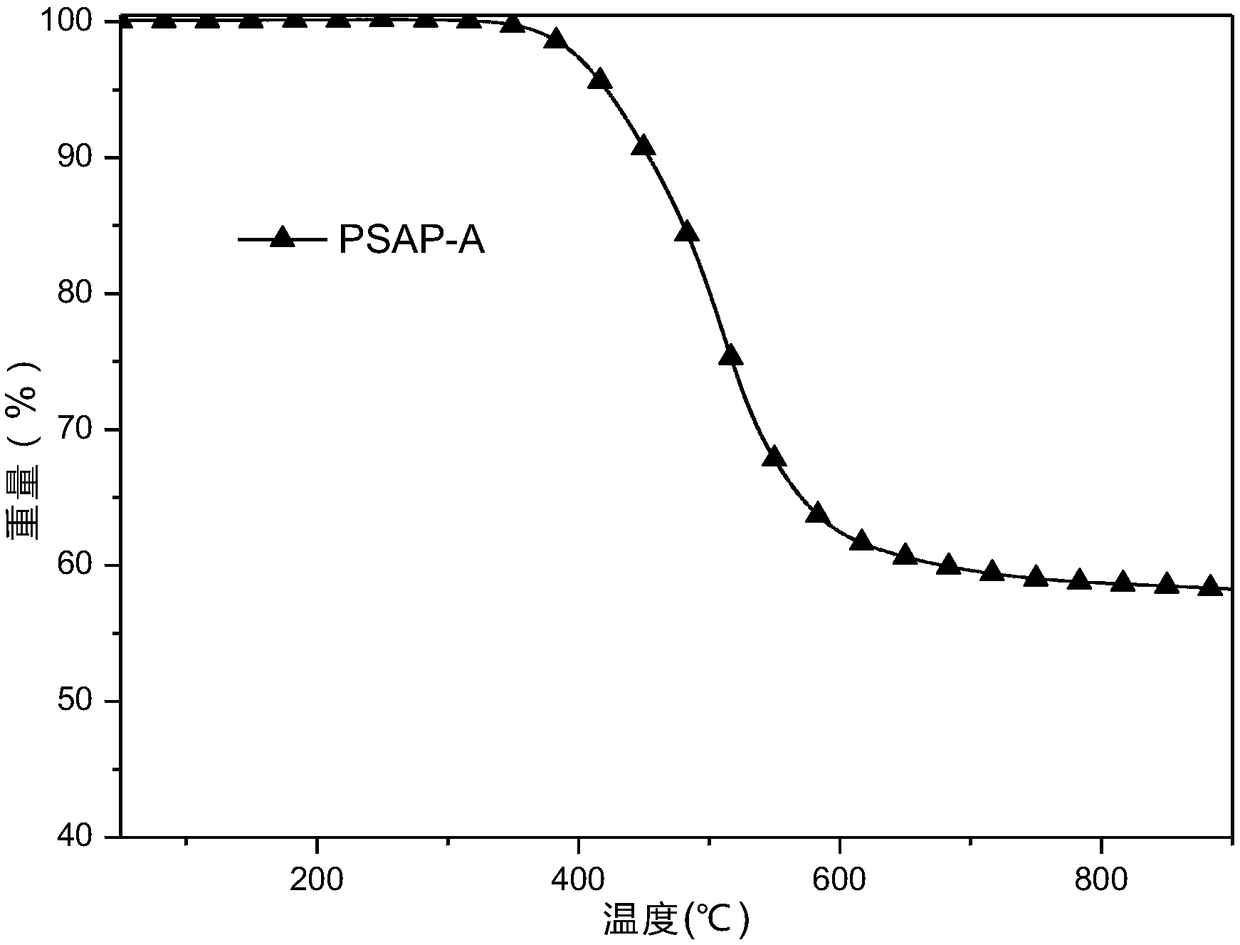

[0046] In the data testing part, the structure of the resin is tested by a hydrogen nuclear magnetic resonance instrument. The curing reaction temperature of resin can be tested by differential scanning calorimeter (DSC), and the initial temperature of curing reaction (T i ), and curing reaction peak temperature (T p ), curing reaction end temperature (T f ) and the exothermic enthalpy of the curing reaction (ΔH). The curing process of the resin can be determined by referring to the results of the resin DSC test. The thermal stability of the thermally cured resin can be tested in a nitrogen atmosphere with a thermogravimetric analyzer (TGA), and the 5% thermal weight loss...

Embodiment 2

[0069] Preparation of cyanate ester, P-appe and silicon-containing bisphenol A propargyl ether blend resin and preparation of composite materials

[0070] Bisphenol E type dicyanate (BEDCy), benzoxazine (P-appe) and silicon-containing bisphenol A dipropargyl ether resin (the PSAP-A resin raw material that embodiment 1 obtains) according to mass ratio 15 :15:70 dissolved in tetrahydrofuran solution, stirred for 30 minutes, after mixing evenly, after vacuum rotary evaporation and cooling, the modified ternary system resin can be obtained. Dissolve this resin in acetone and prepare a solution with a mass fraction of 38%. The carbon fiber cloth (T300) is impregnated with the above solution to obtain a prepreg. After the volatile content is less than 1%, the prepreg is laminated and Compressed on a flat press. The pressing process is 210°C / 2h, 250°C / 2h, 300°C / 2h and 330°C / 4h, the molding pressure is 3MPa, and the rubber content of the prepared composite material is about 30%. The...

Embodiment 3

[0072] Preparation of cyanate ester, benzoxazine P-apa and silicon-containing bisphenol A propargyl ether blend resin and preparation of composite materials

[0073] Bisphenol A type dicyanate (BADCy), benzoxazine (P-apa) and silicon-containing bisphenol A dipropargyl ether resin (the PSAP-A raw material that embodiment 1 obtains) according to mass ratio 15: 15:70 was dissolved in tetrahydrofuran solution, stirred for 30 minutes, mixed evenly, and then cooled by rotary evaporation under reduced pressure to obtain the modified ternary system resin. Dissolve this resin in acetone and prepare a solution with a mass fraction of 38%. The carbon fiber cloth (T300) is impregnated with the above solution to obtain a prepreg. After the volatile content is less than 1%, the prepreg is laminated and Compressed on a flat press. The pressing process is 210°C / 2h, 250°C / 2h, 300°C / 2h and 330°C / 4h, the molding pressure is 3MPa, and the rubber content of the prepared composite material is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com