Flame-retardant polyurethane elastomer and its preparation method and application

A polyurethane elastomer and flame-retardant technology, which is applied in the field of flame-retardant polyurethane elastomer and its preparation, can solve the problems that the research on the flame-retardant and smoke-suppressing properties of mixing-type polyurethane elastomer materials has not been reported, and achieve excellent The effect of low smoke characteristics, wide source, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

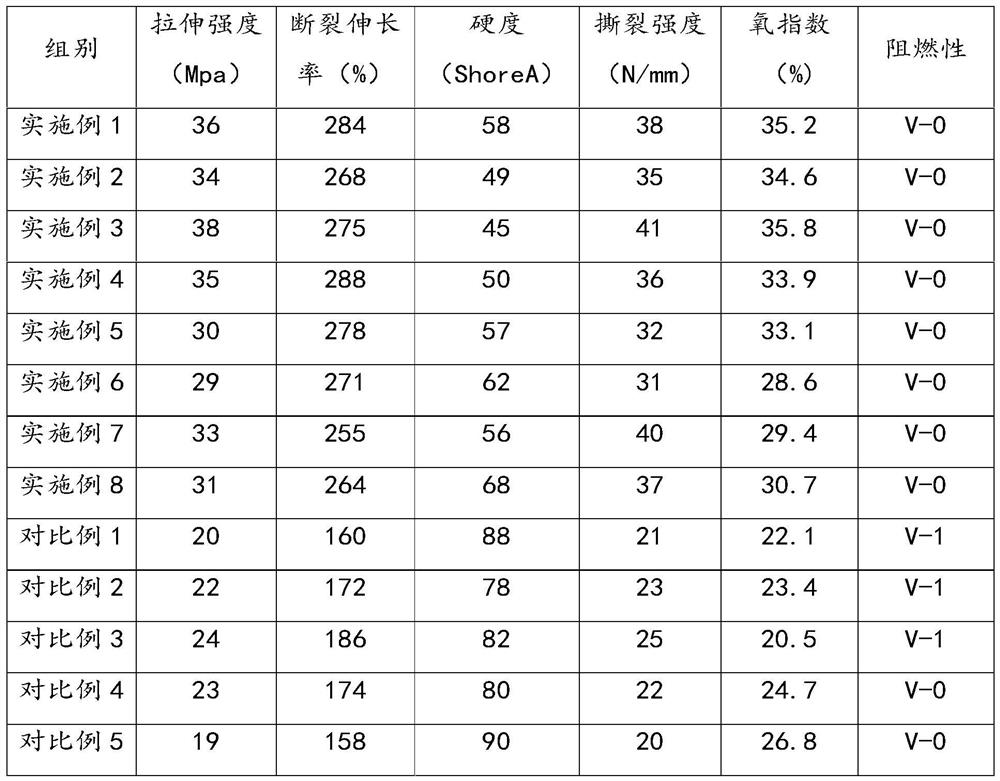

Examples

preparation example Construction

[0087] In a second aspect, a method for preparing the above-mentioned flame-retardant polyurethane elastomer is provided, comprising the following steps:

[0088] Mix the raw materials in the formula quantity evenly, and then carry out banburying and kneading to obtain the mixture;

[0089] The mixture is vulcanized and foamed to obtain the flame-retardant polyurethane elastomer.

[0090] Preferably, each raw material in the formulation amount is mixed uniformly in a high-speed mixer.

[0091] The above preparation method has simple operation, easy control of the preparation process, high production efficiency, and good quality stability of the prepared product, which is suitable for large-scale industrial production.

[0092] In a preferred embodiment, the banburying temperature is 70-100°C, and the time is 4-16 minutes;

[0093] Preferably, the temperature for kneading is 50-70°C, and the time is 3-10 minutes;

[0094] Preferably, the vulcanization temperature is 170-210°...

Embodiment 1

[0103] A flame-retardant polyurethane elastomer is mainly prepared from the following raw materials in parts by weight:

[0104] 60 parts of polyether type mixing type unsaturated polyurethane raw rubber, 25 parts of vulcanization system, 30 parts of halogen-free flame retardant ammonium phosphate, 12 parts of smoke suppressant ferric oxide, antioxidant tetrakis [methylene-3, 3', 5-(di-tert-butyl-4-hydroxy-phenyl) propionate] pentaerythritol ester 0.5 parts, anti-aging agent N-phenyl-α-aniline 0.5 parts, stabilizer zinc stearate 0.6 parts, anti-aging agent 0.8 parts of hydrolyzing agent carbodiimide, 0.5 parts of anti-rodent masterbatch, 0.5 part of anti-termite masterbatch and 1 part of foaming agent azodicarbonamide;

[0105] Wherein, the vulcanization system includes the following components in parts by weight:

[0106] 100 parts of unsaturated polyurethane raw rubber, 1 part of stearic acid, 1 part of zinc stearate, 10 parts of carbon black, 20 parts of precipitated silic...

Embodiment 2

[0108] A flame-retardant polyurethane elastomer is mainly prepared from the following raw materials in parts by weight:

[0109]100 parts of polyether mixing type unsaturated polyurethane raw rubber, 40 parts of vulcanization system, 70 parts of ammonium phosphate, halogen-free flame retardant, 25 parts of iron sesquioxide, anti-oxidant tetrakis [methylene-3, 3', 5-(di-tert-butyl-4-hydroxy-phenyl) propionate] pentaerythritol ester 1.5 parts, anti-aging agent N-phenyl-α-aniline 1.5 parts, stabilizer zinc stearate 1.8 parts, anti-aging agent 1.8 parts of hydrolyzing agent carbodiimide, 3 parts of anti-rodent masterbatch, 3 parts of anti-termite masterbatch and 6.5 parts of foaming agent azodicarbonamide;

[0110] Wherein, the vulcanization system is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com