Method for preparing metal structural part with complex shape through 3D cold printing

A technology for metal structural parts and complex shapes, used in metal processing equipment, transportation and packaging, additive processing, etc. Low fluidity requirements, complete shape without breakage, and the effect of reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

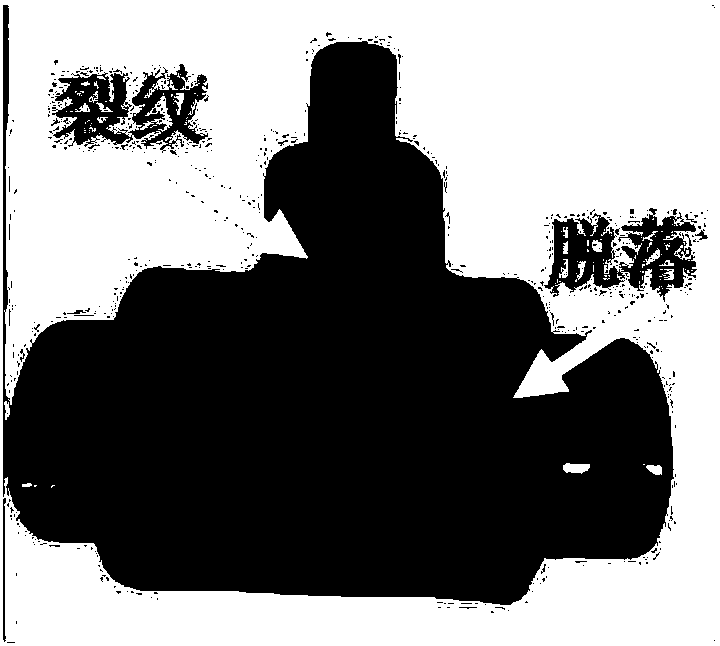

[0029] A 3D cold printing preparation of complex-shaped titanium tee components, the composition of the new cold isostatic wrapping raw materials is as follows:

[0030] Glucose 4%, barley flour 58%, glycerin 2%, butter oil 4%, ovalbumin 0.4%, triethanolamine 1.2%, starch syrup 2.8%, sodium chloride 1%, sodium bicarbonate 1.5%, hydrogen tartrate Potassium 0.9%, citric acid 0.6%, edetate disodium 0.3%, sodium alginate 1.5%, methylcellulose 2%, chitosan 1.5%, and the balance is water. Specific steps are as follows:

[0031] (1) Glucose, barley flour, sodium chloride, sodium bicarbonate, potassium hydrogen tartrate, citric acid, disodium edetate, ovalbumin, triethanolamine, syrup, glycerin, butter Oil, sodium alginate, methylcellulose, chitosan and water are mixed, stirred into a paste, and a slurry is prepared.

[0032] (2) Put the slurry into the 3D cold printing machine, print out the cold isostatic pressing body of the tee layer by layer, put it into the steam box for heati...

Embodiment example 2

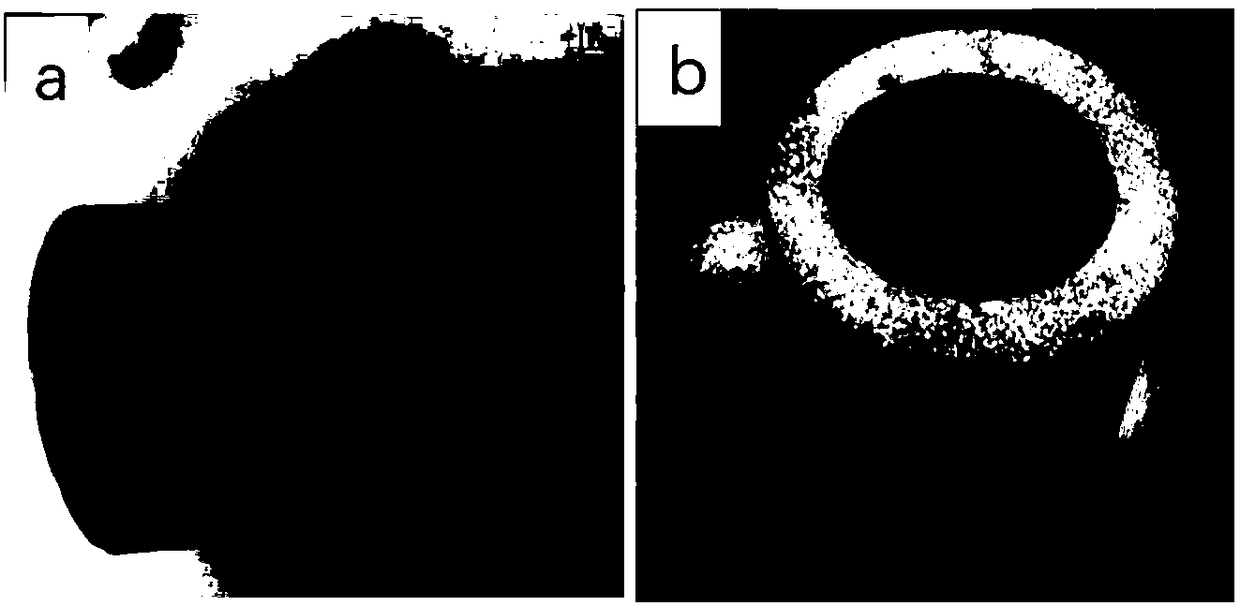

[0038] A YG6 cemented carbide multi-stage gear member with a complex shape prepared by 3D cold printing. The raw material ratio of the new cold isostatic pressing sleeve is as follows:

[0039] Glucose 3%, wheat flour 60%, glycerin 3%, butter oil 2%, ovalbumin 0.45%, triethanolamine 1.3%, starch syrup 1.0%, sodium chloride 1.2%, sodium bicarbonate 1.5%, hydrogen tartrate Potassium 1.0%, oleic acid 0.7%, edetate disodium 0.32%, sodium alginate 1.6%, methylcellulose 2.2%, chitosan 1.3%, and the balance is water.

[0040] Specific steps are as follows:

[0041] (1) Glucose, wheat flour, sodium chloride, sodium bicarbonate, potassium hydrogen tartrate, oleic acid, disodium edetate, ovalbumin, triethanolamine, syrup, glycerin, butter Oil, sodium alginate, methylcellulose, chitosan and water are mixed, stirred into a paste, and a slurry is prepared. ;

[0042] (2) Put the slurry into a 3D cold printing machine, print out the cold isostatic pressing body of the multi-stage gear la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com