Catalytic oxygen evolution electrode and preparation method and application thereof

A technology for oxygen evolution electrodes and catalysts, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of high catalyst preparation costs, affecting catalytic activity, expensive noble metal catalysts, etc., achieve catalytic activity without breaking the ring, and improve compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Prepare 1mol L of analytical pure KOH and high-purity water -1 The electrolytic solution is fed with high-purity oxygen until the electrolyte is saturated with oxygen, and the experimental temperature is room temperature 25°C;

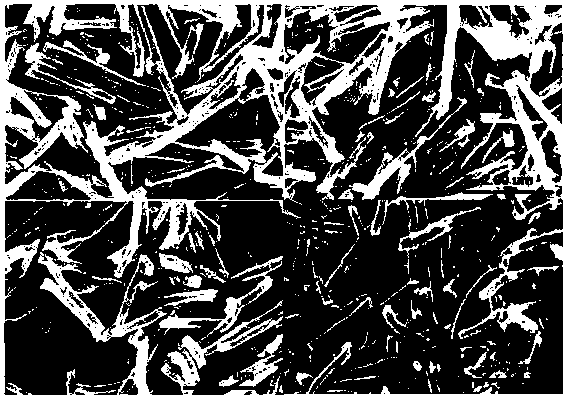

[0044] (2) PrBa with an oxygen evolution catalyst active material diameter of 200nm 0.5 Sr 0.5 co 1.5 Fe 0.5 o 5+α Nanowires, dispersed in a mixed solution of isopropanol, ultrapure water and 5wt.% NafionPFSAPolymer Dispersions D520 (produced by DuPont), to obtain a concentration of 5mg mL -1 Obtain catalyst solution, isopropanol, ultrapure water and 5wt.%NafionPFSAPolymer Dispersions D520 volume ratio in mixed solution are 45%: 45%: 10%, and all embodiments of the present invention use perfluorinated sulfonic acid resin to be 5wt.%Nafion PFSA The mixed solution of Polymer Dispersions D520 (produced by DuPont);

[0045] (3) Under room temperature conditions, the catalyst solution prepared in step (2) was ultrasonically treated for 3 ho...

Embodiment 2

[0054] (1) Prepare 1mol L of analytical pure KOH and high-purity water -1 The electrolytic solution is fed with high-purity oxygen until the electrolyte is saturated with oxygen, and the experimental temperature is room temperature 25°C;

[0055] (2) The abrasive tool cuts out a circular carbon paper with a diameter of 16.2 mm;

[0056] (3) put the carbon paper described in step (2) into the electrolytic solution prepared in step (1), carry out relative to saturated Ag / AgCl reference electrode negative pressure 0.6V constant voltage treatment 1200s, obtain the carbon paper of negative pressure treatment Paper electrodes.

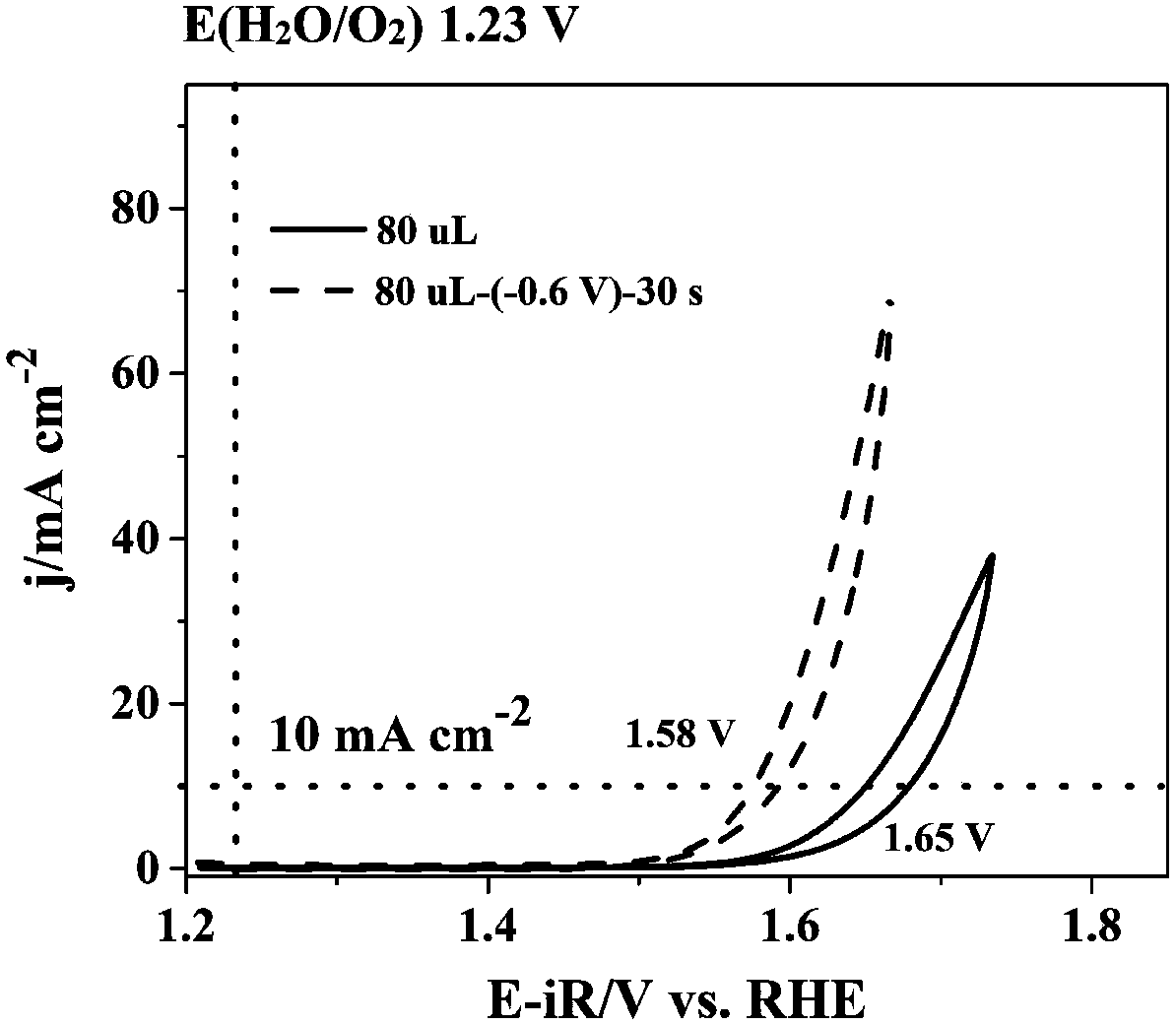

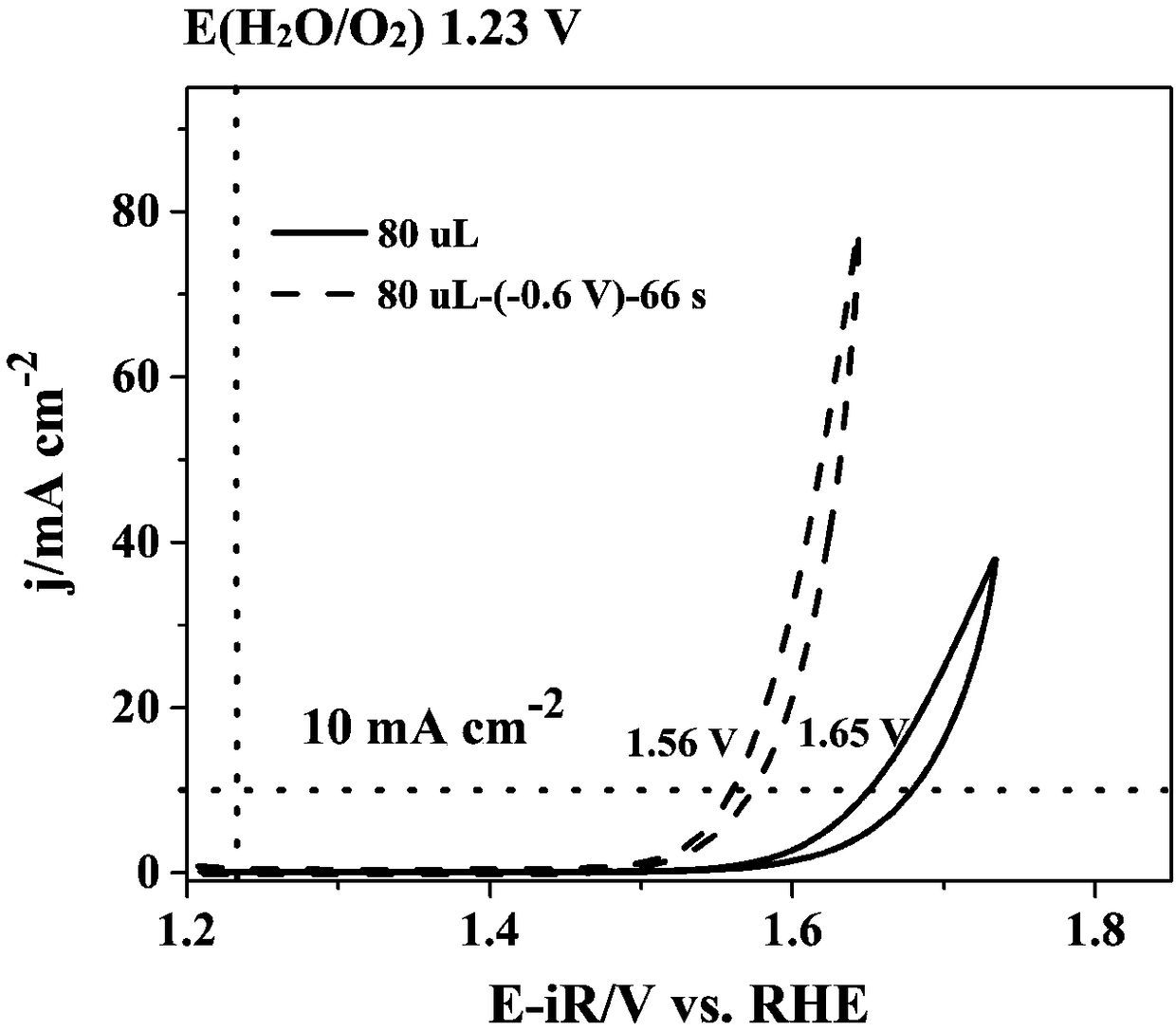

[0057] The prepared carbon paper electrode was tested for oxygen evolution activity, and the test results were as follows: Figure 8 shown.

Embodiment 3

[0061] (1) Prepare 1mol L of analytical pure KOH and high-purity water -1 The electrolytic solution is fed with high-purity oxygen until the electrolyte is saturated with oxygen, and the experimental temperature is room temperature 25°C;

[0062] (2) The oxygen evolution catalyst active material IrO 2 Dispersed in a mixed solution of isopropanol, ultrapure water and 5wt.% NafionPFSA Polymer Dispersions D520 (manufactured by DuPont) to obtain a concentration of 5mg mL -1 Obtain the catalyst solution, the volume ratio of isopropanol, ultrapure water and 5wt.% Nafion PFSA Polymer Dispersions D520 in the mixed solution is 45%: 45%: 10%;

[0063] (3) ultrasonically treating the catalyst solution prepared in step (2) for 3 hours to obtain a homogeneously dispersed catalyst suspension;

[0064] (4) A circular carbon paper with a diameter of 16.2 mm was cut out with an abrasive tool as a substrate for supporting the electrode active material.

[0065] (5) Use a micropipette to pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com