Near-infrared fluorescent powder, preparation method of fluorescent powder and light-emitting device containing fluorescent powder

A light-emitting device and phosphor technology, applied in the field of fluorescent materials, can solve problems such as low luminous efficiency, achieve the effects of high luminous efficiency, high emission performance, and widen application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The near-infrared fluorescent powder described in this embodiment, the compound composition formula that it comprises is LaGd 2 Ga 4.82 GeO 13.97 : 0.12Cr, 0.06Zn.

[0039] According to the chemical formula LaGd 2 Ga 4.82 GeO 13.97 : 0.12Cr, 0.06Zn stoichiometric ratio, accurately weighed La2 o 3 , Ga 2 o 3 、Gd 2 o 3 、GeO 2 and Cr 2 o 3 , ZnO mixed to obtain a mixture; the mixture was ground and mixed and then calcined at 1300°C for 5 hours, and the roasted product was obtained after cooling down; the obtained roasted product was subjected to post-processing such as crushing, grinding, grading, and sieve washing. Obtain near-infrared phosphor samples.

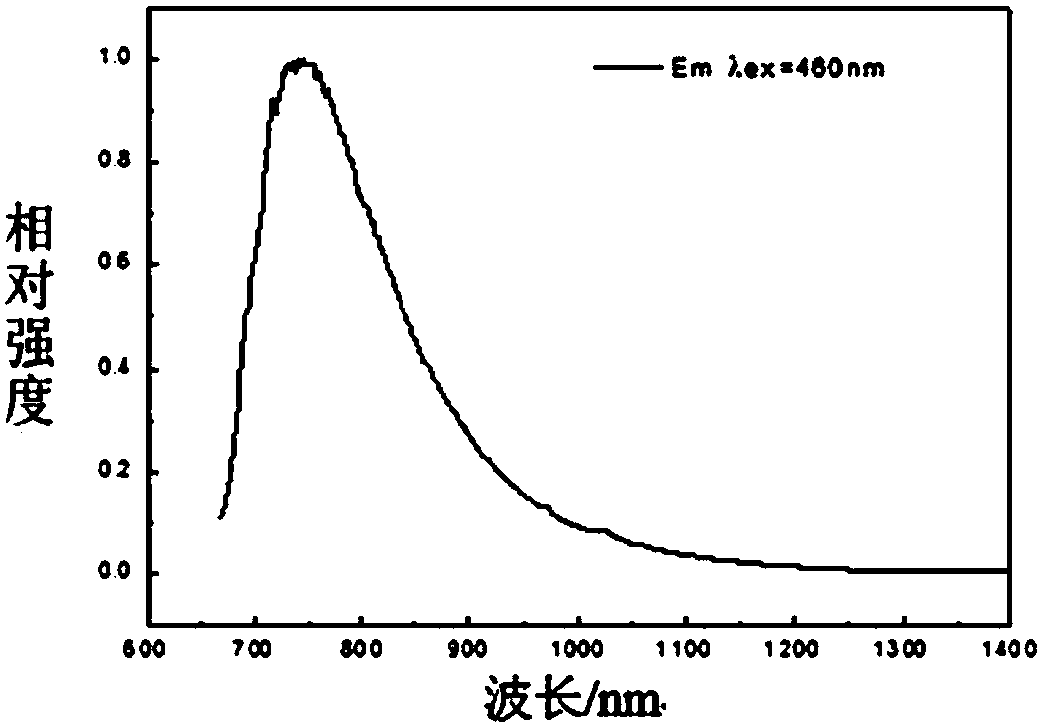

[0040] The obtained near-infrared phosphor sample was subjected to an excitation test, and the excitation and emission spectra of the sample were obtained as attached figure 1 with figure 2 shown. It can be seen from the results in the figure that the near-infrared phosphor sample can be effectively exci...

Embodiment 2

[0042] The near-infrared fluorescent powder described in this embodiment comprises a compound whose composition formula is La 1.5 Gd 1.5 Ga 4 GeO 11 : 0.5Cr.

[0043] According to chemical formula La 1.5 Gd 1.5 Ga 4 GeO 11 : 0.5Cr stoichiometric ratio, accurately weighed La 2 o 3 、Gd 2 o 3 , Ga 2 o 3 、GeO 2 and Cr 2 o 3 Mix to obtain a mixture; after the mixture is ground and mixed, it is calcined at 1200°C for 5 hours, and the roasted product is obtained after cooling down; the obtained roasted product is subjected to post-processing such as crushing, grinding, grading, and sieve washing to obtain a near-infrared Phosphor samples.

[0044] The obtained near-infrared phosphor sample was subjected to an excitation test, and the result showed that the emission peak position of the near-infrared phosphor sample was located at 780 nm when excited at 460 nm.

Embodiment 3

[0046] The near-infrared fluorescent powder described in this embodiment, the compound composition formula that it comprises is Gd 3 Ga 4 al 0.5 GeO 14 : 0.5Cr.

[0047] The preparation method of the near-infrared phosphor described in this example is the same as that in Example 2, the only difference being that, according to the chemical formula of the target compound, an appropriate amount of compound is selected for mixing, grinding, and roasting to obtain the required near-infrared phosphor material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com