Near-infrared broadband emission luminescent material, preparation method thereof and luminescent device containing near-infrared broadband emission luminescent material

A technology of luminescent materials and light-emitting devices, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., and can solve the problems of further improvement of luminous efficiency and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0052] Examples 1-10: RX 3-x (BO 3 ) 4 :xCr 3+ Preparation of Luminescent Materials

[0053] Examples 1-10 were synthesized by a solid-state reaction method, and the difference lies in the type, amount and synthesis temperature of raw materials. Table 1 lists the types and amounts of raw materials used.

[0054] The concrete steps of synthesis are:

[0055] 1. According to the chemical formula RX 3-x (BO 3 ) 4 :xCr 3+ The stoichiometric ratio of each element in the formula, the oxygen-containing compound of the R element, the oxygen-containing compound of the X element, and the Cr 2 o 3 and H 3 BO 3 , H 3 BO 3 An excess of 5wt% is used as a flux.

[0056] 2. After adding alcohol to mix the raw materials evenly, put the mixture into a crucible and put it into a heating device for calcination. The calcination conditions are: the raw material is now calcined at 500°C for 4 hours, take out the raw material, grind it again, and put it into a box furnace , carry out s...

Embodiment 10-19

[0061] Examples 10-19: RX 3-x (BO 3 ) 4 :xCr 3+ Preparation of Luminescent Materials

[0062] Examples 10-19 are synthesized by a solid-state reaction method, and their chemical formulas correspond to those of Examples 1-10, the difference is that the required raw materials are weighed according to the stoichiometric ratio, and the flux used is CaF 2 、BaF 2 , MgF 2 , AlF 2 、K 2 SO 4 、LiCO 3 etc., the synthesis temperature is 50° C. lower than that of Examples 1-10. Other processes are consistent with Example 1-10.

[0063] Table 2. Preparation parameters of Examples 10-19

[0064]

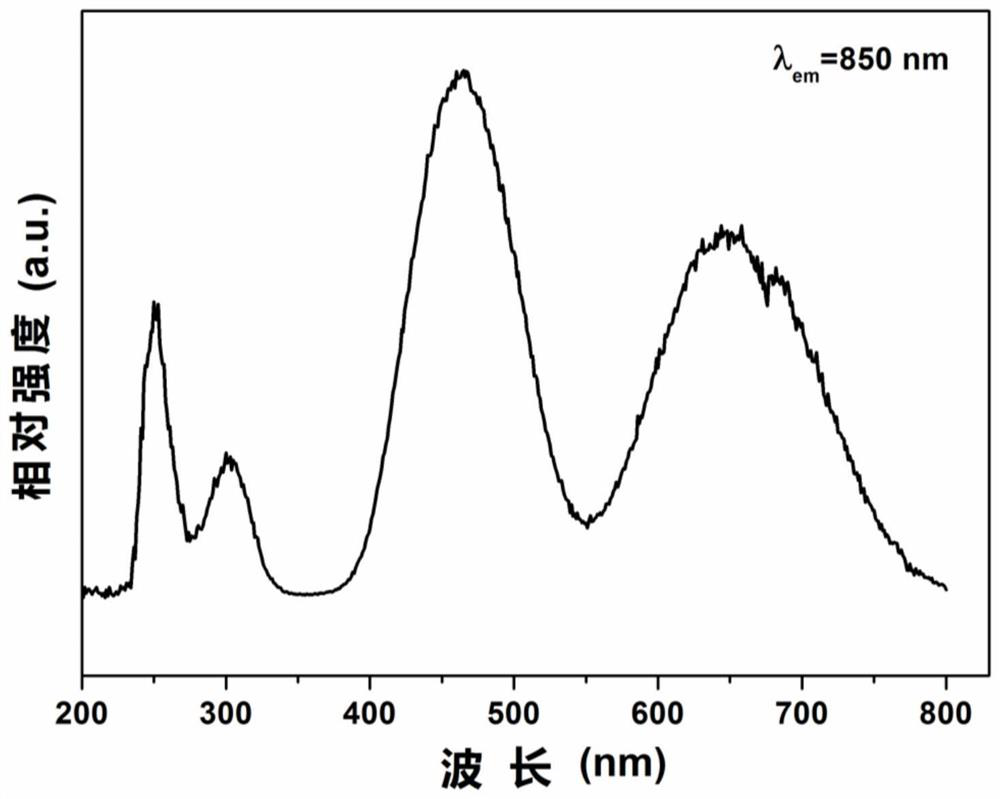

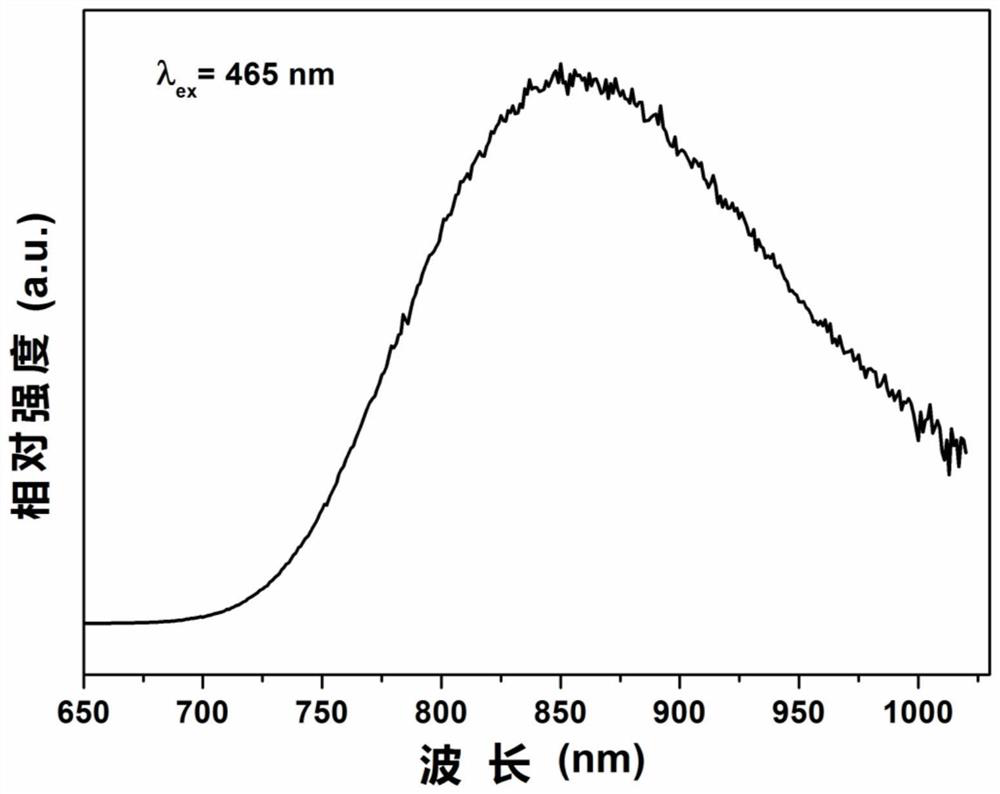

[0065] Spectral properties of the sample were measured with a FLS980 (Edinburgh Instruments) fluorescence spectrometer, and phase analysis of the sample was performed with an X-ray diffractometer (DMAX2500PC, Rigaku, Japan).

[0066] The samples synthesized by the solid phase reaction method, XRD analysis shows that they are all pure phases, such as figure 1 The XRD pattern of the s...

Embodiment 20

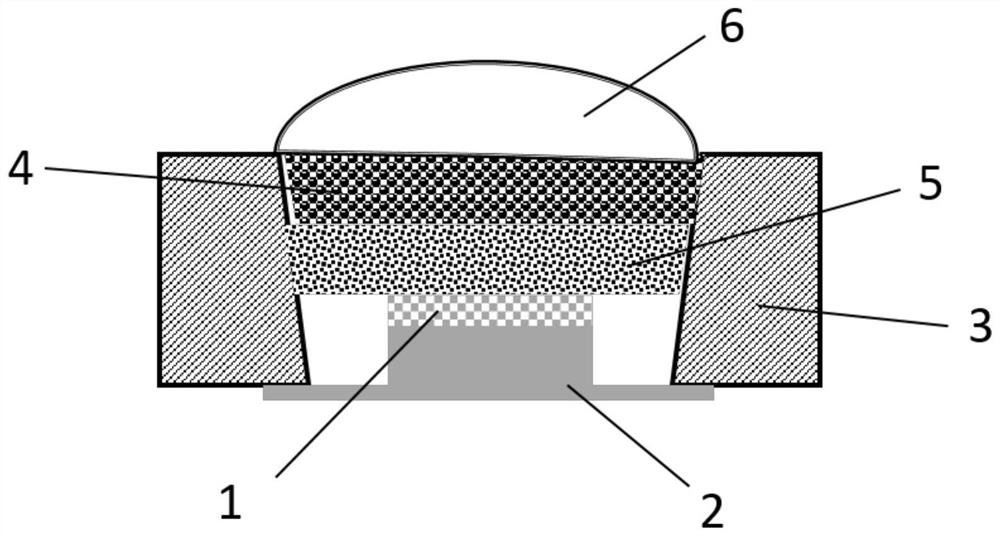

[0071] This embodiment provides an LED light-emitting device containing near-infrared light-emitting materials, the structure of which is as follows image 3 As shown, the light emitting device includes an LED chip 1 , a heat sink 2 , a base 3 , a light conversion part B 4 , a light conversion part A 5 and a lens 6 . The LED chip 1 is used as a light source, the heat sink 2 is arranged under the LED chip 1, the LED chip 1, the light conversion part A5 and the light conversion part B4 are arranged in order from bottom to top, and the lens 6 is located above the light conversion part 4.

[0072] The light conversion part A5 absorbs the primary light emitted by the LED chip 1 and converts it into secondary light of a higher wavelength, and the light conversion part B4 absorbs the primary light emitted by the LED chip 1 and the secondary light emitted by the light conversion part A5, and converts them to Converted to higher wavelength tertiary light.

[0073] The light-emitting d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com