High-electrical-performance halogen-free flame-retardant reinforcement nylon composite material

A nylon composite material and electrical performance technology, which is applied in the field of high electrical performance halogen-free flame-retardant reinforced nylon composite materials, can solve the problems of limited improvement in impact strength, reduced performance of flame retardants and nylon, impact performance of short glass fibers, etc. , to achieve the effect of improving mechanical properties, reducing shearing effect, and fine and regular grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

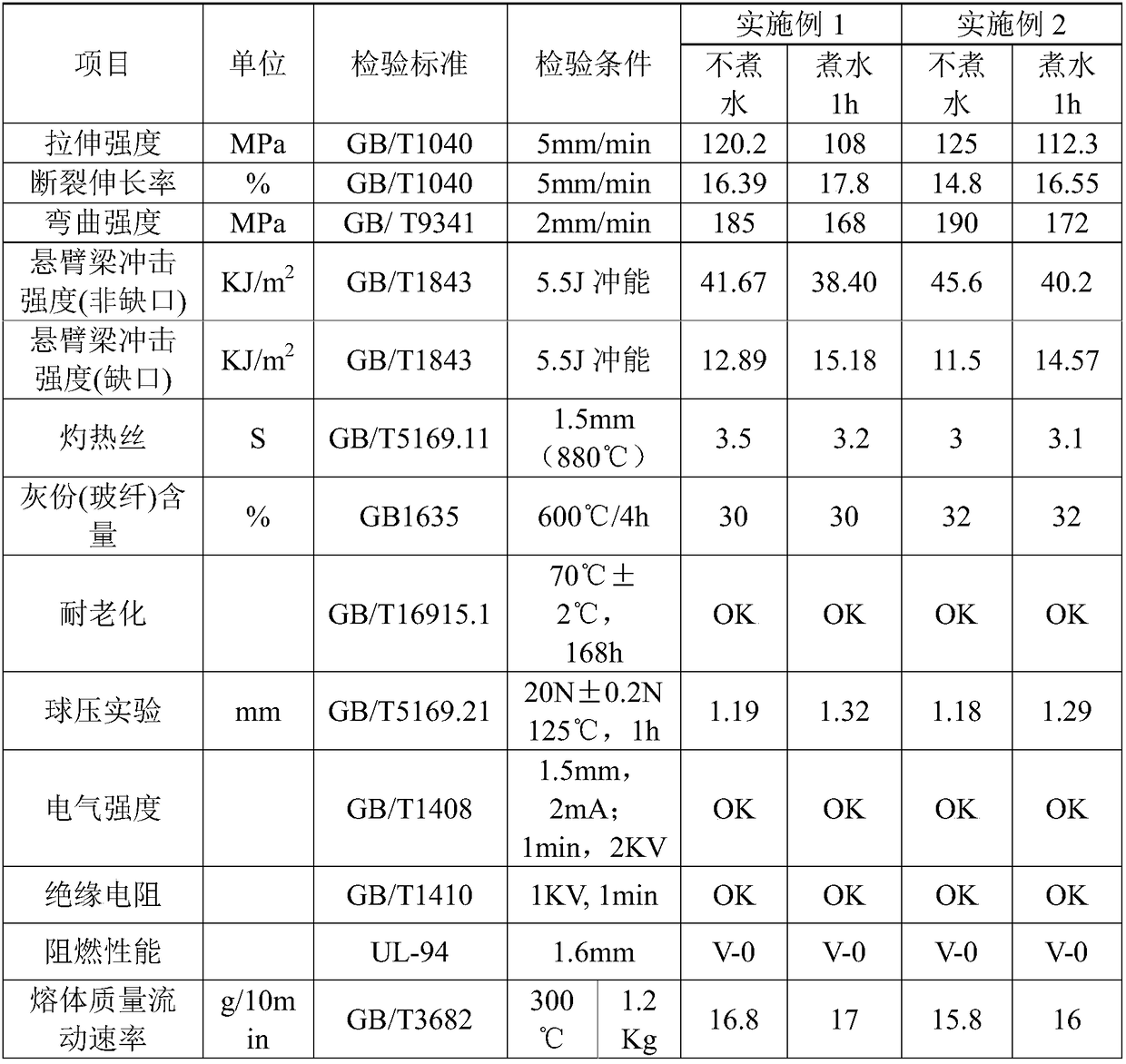

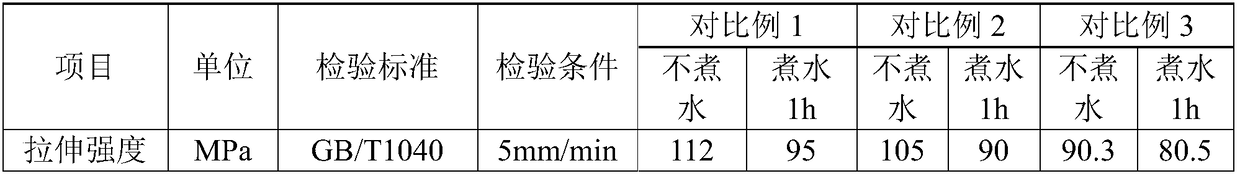

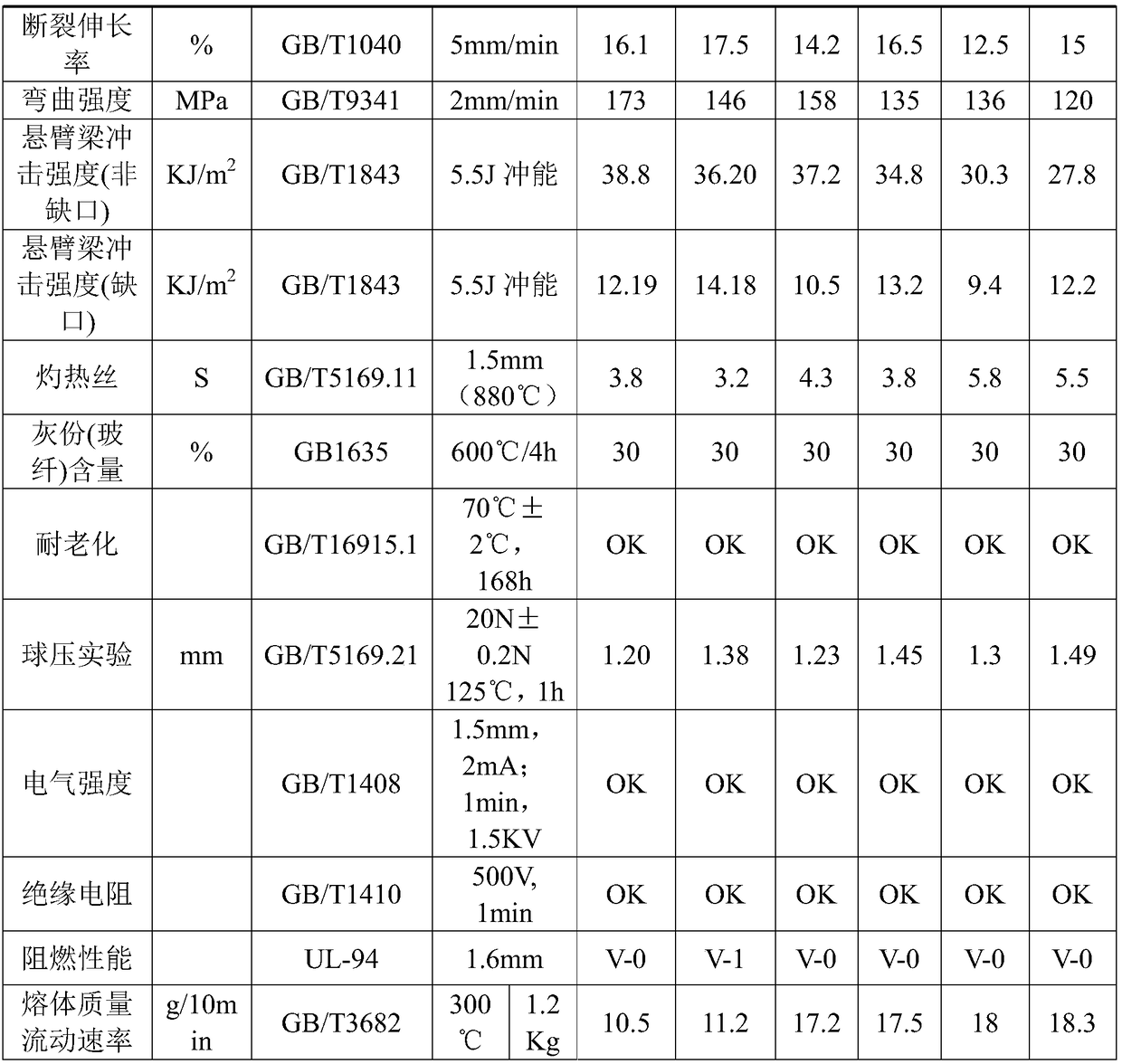

Examples

Embodiment 1

[0028] In this example, the high-viscosity nylon 66 is 21SPC produced by Solutia Corporation of the United States; the glass fiber is Taishan glass fiber TCR735-2000; The diameter is 11 μm; the nucleating agent is P-22 produced by Jining Beijia Company; the toughening agent maleic anhydride grafted POE is selected from PC-28 produced by Foshan Nanhai Baichen Company; the flow agent is Italian hair base PETS- AP; Masterbatch is Cabot Black.

Embodiment 2

[0030] Referring to the raw materials of Example 1, the difference is that the polytetrafluoroethylene particle size is 12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com