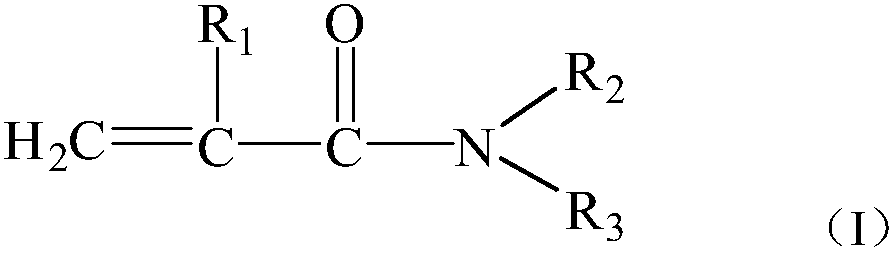

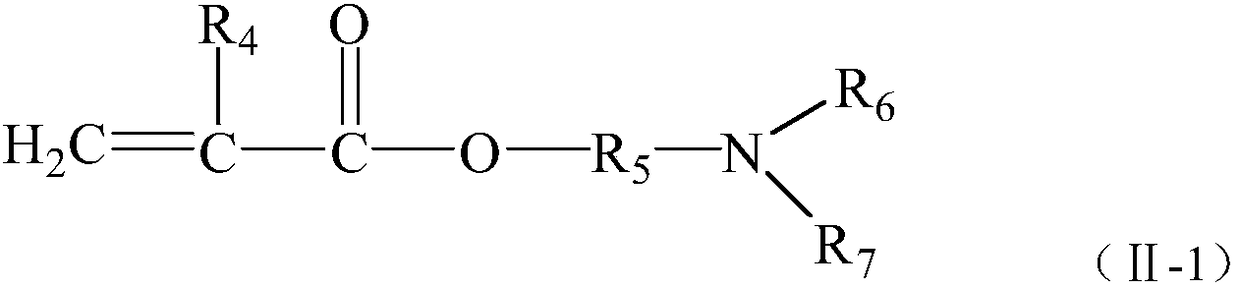

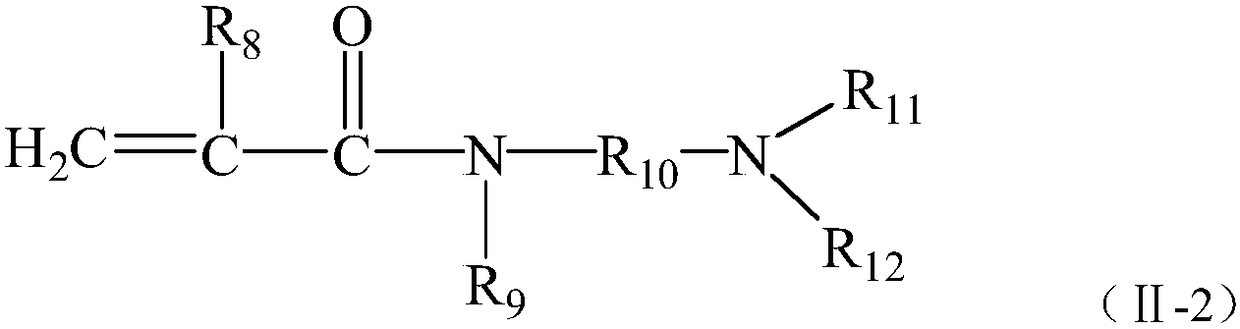

Water-soluble solid polyacrylamide and application thereof

A polyacrylamide, water-soluble technology, applied in the field of water-soluble polymer materials, can solve the problems of poor storage stability, low molecular weight, high content of effective substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] (1) Uniformly mixing chain transfer agent, pH regulator, chelating agent, water and / or organic solvent and surfactant to form a mixed solution;

[0113] (2) Place four types of monomers, nonionic monomer A, nonionic monomer B, anionic monomer and cationic monomer, in the mixed liquid, and deoxygenate it by an inert gas;

[0114] (3) Apply triggering conditions to carry out chain polymerization, and obtain water-soluble polyacrylamide polymer in aqueous solution system or suspension system. The obtained polymer is liquid, or colloidal, or granular, and the polymer is dried, sieved Graded processing means become granular and / or powdery water-soluble solid polyacrylamide products.

[0115] Specifically: by weight, deionized water, chain transfer agent, chelating agent, pH regulator, non-ionic monomer A, non-ionic monomer B, cationic monomer, and anionic monomer are mixed evenly, and nitrogen gas is used to remove oxygen for 30 After the reaction, the temperature of the co...

Embodiment 21

[0156] Use 350 parts of cyclohexane and 20 parts of Span-80 as the primer, heat to dissolve, mix well, condense and reflux, pass inert gas to remove oxygen while stirring, and raise the temperature to 70°C. Then 98 parts of acrylamide, 30 parts of dimethylaminoethyl methacrylate, 14 parts of methacryloyloxyethyltrimethylammonium chloride, 6 parts of dimethyl diallyl ammonium chloride, 11 parts of acid, 1 part of isopropanol, 0.03 parts of EDTA-2Na, 2.5 parts of dilute hydrochloric acid, and 153 parts of deionized water are fully dissolved as dropping materials, and 0.2 parts of ammonium persulfate and 0.1 parts of V50 are dissolved in 5 parts of deionized water Then add it to the dropping material and stir evenly, then slowly add it dropwise to the bottom material for 1.5 hours, keep it warm for 1 hour after the dropping, then raise the temperature to 75°C for 1 hour, add 0.5 part of liquid paraffin, and cool down to room temperature, The organic oil phase was separated and re...

Embodiment 22

[0158]Use 350 parts of n-heptane and 22 parts of Span-40 as the base material, heat to dissolve, mix well, condense and reflux, pass inert gas to remove oxygen while stirring, and heat up to 70°C. Then 73.5 parts of acrylamide, 5 parts of N,N-dimethylacrylamide, 50 parts of dimethylaminoethyl methacrylate, 14 parts of acryloyloxyethyltrimethylammonium chloride, 22 parts of acrylic acid, sodium formate 0.2 parts, 0.03 parts of EDTA-2Na, 2 parts of dilute sulfuric acid, and 121 parts of deionized water are fully dissolved as the dropping material, and 0.2 parts of ammonium persulfate is dissolved in 2 parts of deionized water and then added to the dropping material and stirred evenly. Then it was slowly added dropwise to the base material for 1.5 hours, kept warm for 1 hour after the dropwise addition, then raised to 75°C for 1 hour, added 0.5 parts of liquid paraffin, lowered to room temperature, and quickly filtered to separate and remove the organic oil phase. The polymer was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com