A kind of preparation method of composite ceramic coating on the surface of carbon/carbon composite material

A technology of carbon composite materials and ceramic coatings, applied in the field of aerospace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

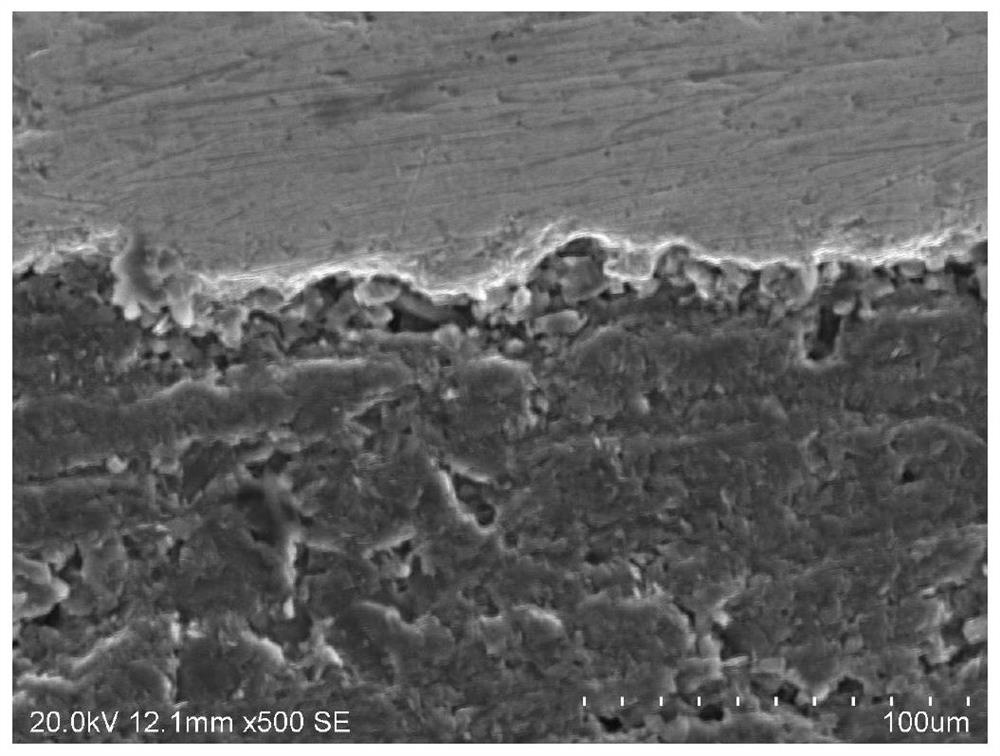

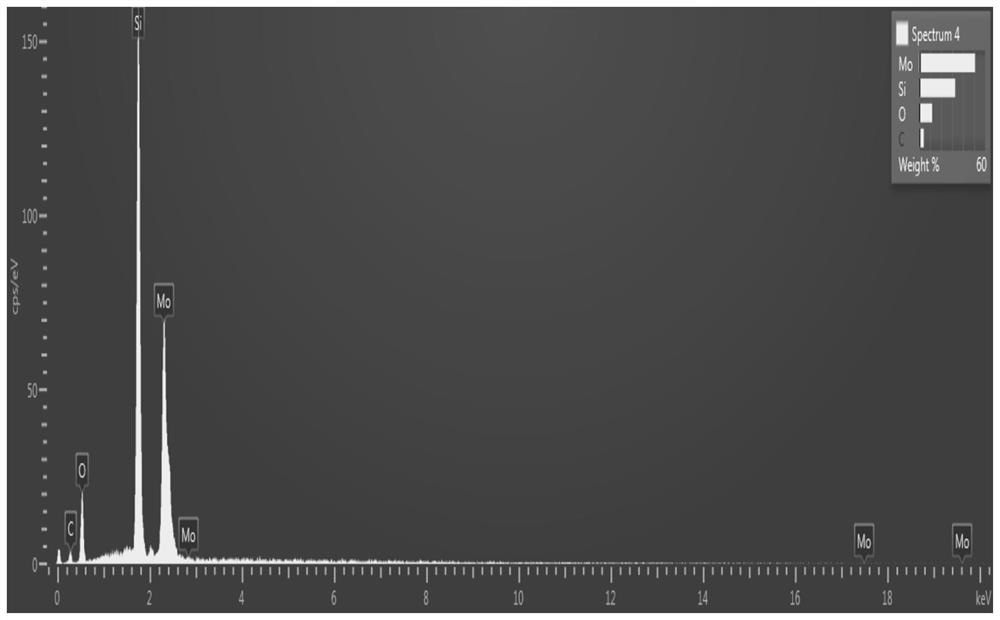

[0062] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material, comprising the steps of:

[0063] Step 1, SiC-MoSi on carbon / carbon composite surface 2 Pre-coat preparation:

[0064] (1) According to the quantity ratio of substances 2:1:1, take 5g Si powder, 3.5g SiC powder and 13.5g MoSi 2 Mix the powders to form a raw material powder, add polyvinyl alcohol-200, the amount of polyvinyl alcohol-200 added is 8.3% of the raw material powder by mass ratio, use a mortar to grind the raw material powder and binder for 30 minutes and mix to form a mixture , among them, Si powder, SiC powder and MoSi 2 The powder particle size of the powder is 75 μm;

[0065] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.0 g / mL. After standing for 20 minutes, stir again evenly, and evenly coat the suspension on the surface of the C / C composite material. Form a pre-coat layer with a thickness of 0.6mm; ...

Embodiment 2

[0072] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material, comprising the steps of:

[0073] Step 1, SiC-MoSi on carbon / carbon composite surface 2 Pre-coat preparation:

[0074] (1) Take 5.7g of Si powder, 4.1g of SiC powder and 15.5g of MoSi according to the ratio of 2:1:1. 2 Mix the powder to form a raw material powder, add polyvinyl alcohol-200, the amount of polyvinyl alcohol-200 added is 9.0% of the raw material powder by mass ratio, use a mortar to grind the raw material powder and binder for 30 minutes and mix to form a mixture , among them, Si powder, SiC powder and MoSi 2 The powder particle size of the powder is 100 μm;

[0075] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.5g / mL, stir again after standing for 25min, and evenly coat the suspension on the surface of the C / C composite material, Form a pre-coat layer with a thickness of 0.7mm;

[0076] Step 2, after...

Embodiment 3

[0082] A method for preparing a composite ceramic coating on the surface of a carbon / carbon composite material, comprising the steps of:

[0083] Step 1, SiC-MoSi on carbon / carbon composite surface 2 Pre-coat preparation:

[0084] (1) According to the quantity ratio of substances 2:1:1, take 6.4g Si powder, 4.5g SiC powder and 17.4g MoSi 2 Mix the powder to form a raw material powder, add polyvinyl alcohol-600, the amount of polyvinyl alcohol-600 added is 9.3% of the raw material powder by mass ratio, use a mortar to grind the raw material powder and binder for 30 minutes and mix to form a mixture , among them, Si powder, SiC powder and MoSi 2 The powder particle size of the powder is 120μm;

[0085] (2) Add deionized water to the mixture to make a viscous suspension with a concentration of 2.5g / mL, stir again after standing for 25min, and evenly coat the suspension on the surface of the C / C composite material, Form a pre-coat layer with a thickness of 0.8mm;

[0086] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com