Preparation method of N-type PERT dual-side battery

A double-sided cell and double-sided solar cell technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problem of no modification effect on the suede surface of silicon wafers, no improvement in square resistance uniformity, and inability to remove boron-rich layers, etc. problem, achieve the effect of improving passivation effect, improving square resistance uniformity, and battery opening voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

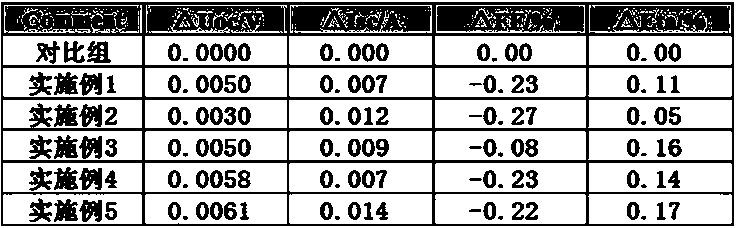

Examples

Embodiment 1

[0026] Select N-type silicon for the following operations: S1: texturing; S2: front boron doping junction; S3: back etching to remove edge and back PN junction; S4: back phosphorus doping junction; S5: removal of back PSG and front BSG; S6: alkali, pickling; S7: wet oxygen passivation; S8: aluminum oxide deposited on the front; S9: SiNx deposited by PECVD on the front; S10: SiNx deposited by PECVD on the back; S11: screen printing and sintering; S12: laser isolation, Get an N-type bifacial battery.

[0027] Step S6 specifically includes: using KOH and hydrogen peroxide mixed solution to micro-etch the surface of the silicon wafer to remove residual impurities, and using HF acid solution to pickle to neutralize the lye and remove the silicon oxide layer on the surface. The mass concentration of KOH in the mixed solution is 2%, the mass concentration of hydrogen peroxide is 5%, the temperature of the mixed solution is 25°C, and the alkaline washing time is 4 minutes. The mass c...

Embodiment 2

[0030] On the basis of Embodiment 1, step S6 and step S7 are further described:

[0031] Step S6 is specifically: use KOH and hydrogen peroxide mixed solution to micro-etch the surface of the silicon wafer and remove residual impurities. The mixed solution has a mass concentration of KOH of 1%, a mass concentration of hydrogen peroxide of 3%, a temperature of the mixed solution of 40°C, and an alkali cleaning time of 4 minutes; Use HF pickling to neutralize the lye and remove the silicon oxide layer on the surface. The mass concentration of the HF acid solution is 7%, the temperature of the acid solution is 25°C, and the pickling time is 3 minutes;

[0032] Step S7 specifically includes: using nitric acid passivation method to passivate the surface of the silicon wafer, the concentration of nitric acid is 63%, the passivation temperature is 25° C., and the time is 6 minutes.

Embodiment 3

[0034] On the basis of Embodiment 1, step S6 and step S7 are further described:

[0035] Step S6 is specifically: use KOH and hydrogen peroxide mixed solution to micro-etch the surface of the silicon wafer and remove residual impurities, the mass concentration of KOH in the mixed solution is 0.5%, the mass concentration of hydrogen peroxide is 1.5%, the temperature of the mixed solution is 60°C, and the alkali cleaning time is 4 minutes; HF pickling neutralizes the lye and removes the silicon oxide layer on the surface, the mass concentration of HF is 4%, the temperature of the acid solution is 25°C, and the pickling time is 4 minutes;

[0036] Step S7 specifically includes: using nitric acid passivation method to passivate the surface of the silicon wafer, the concentration of nitric acid is 58%, the passivation temperature is 25° C., and the time is 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com