Application of chrome-nickel containing alloy vertical concentrated sulfuric acid cooler in low-temperature-position waste heat recycling device and power generation system comprising same

A waste heat recovery device and chrome-nickel alloy technology, which is applied in steam engine installations, machines/engines, sulfur compounds, etc., can solve the problems of high temperature, difficult recovery of waste heat at low temperature, and reduced equipment corrosion rate, etc., to improve the utilization rate and structure. Compact, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

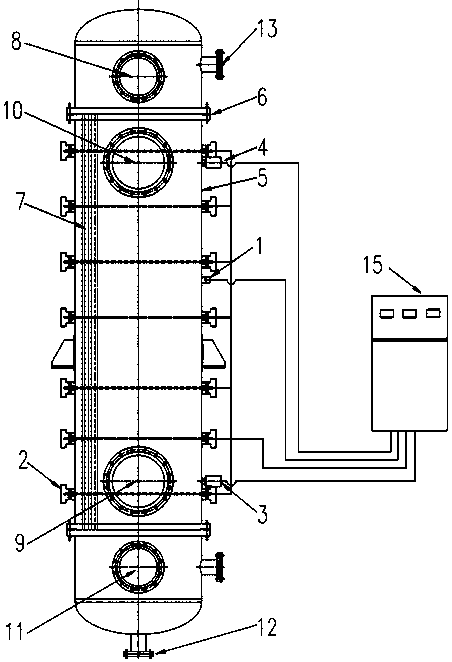

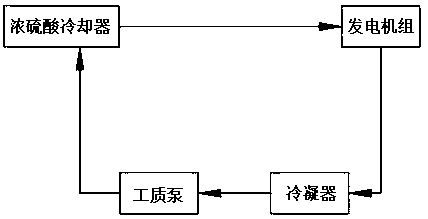

[0028] Embodiment 1, with reference to figure 1 , a low-temperature waste heat recovery device for a chromium-nickel alloy vertical concentrated sulfuric acid cooler. The heat pipe bundle 7, the tube plate 6, and the cylinder body 5 are used as anodes; the two ends of the cylinder body 5 are provided with a tube box, and the tube box is provided with a working medium inlet and outlet, and an exhaust port, and the end of the tube box is provided with a head or flat Cover, and the insulating and sealing control reference electrode 3 is installed on the acid inlet side of the cylinder body 5, and the monitoring reference electrode 4 is installed on the acid outlet side of the cylinder body 5, and the potentiostat 15 connects the anode and cathode 2 , the control reference electrode 3 and the monitoring reference electrode 4 are electrically connected to form the anode protection system; the cylinder 5 and the heat exchange tube bundle 7 installed therein are all placed perpendicu...

Embodiment 2

[0031] Embodiment 2, with reference to figure 1 , One of the cathode support methods: a low-temperature waste heat recovery device for a vertical concentrated sulfuric acid cooler, in which multiple cathodes 2 run through the cylinder 5 and are connected in parallel outside the cylinder 5 by wires and cables. The rest are the same as embodiment 1.

Embodiment 3

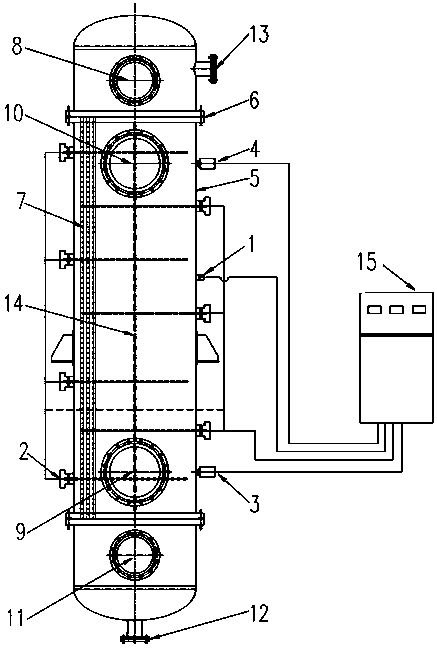

[0032] Embodiment 3, with reference to figure 2 , The second way of cathode support: a low-temperature waste heat recovery device for a vertical concentrated sulfuric acid cooler, in which multiple cathodes 2 are supported by cathode supports 14 and then arranged in parallel and staggered in the cylinder 5 . The cathode support 14 is a support bar or a support tube arranged along the direction of the cylinder, which is used to ensure the support of the cathode inside the equipment and avoid large-scale opening of the cylinder. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com