Application of chrome-nickel containing alloy concentrated sulfuric acid cooler in low-temperature-position waste heat recycling device and power generation system thereof

A waste heat recovery device, chromium-nickel alloy technology, applied in steam engine devices, machines/engines, sulfur compounds, etc., can solve problems such as high temperature, reduced corrosion rate of equipment, and difficult recovery of waste heat at low temperature, so as to improve utilization rate and increase Waste heat quality and the effect of expanding the use of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

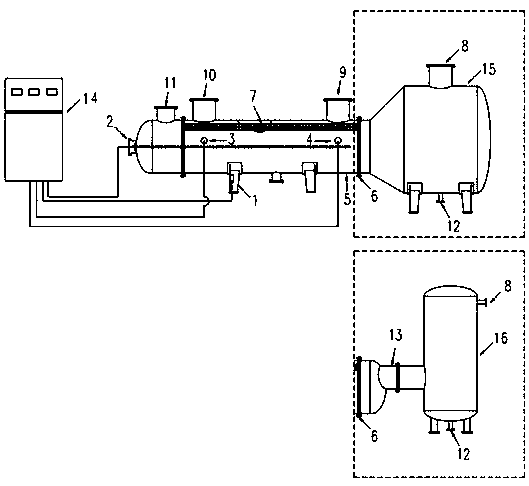

[0023] Embodiment 1, with reference to figure 1 , a low-temperature waste heat recovery device for a concentrated sulfuric acid cooler. The concentrated sulfuric acid cooler has an anode protection system. One or several cathodes 2 connected in parallel are arranged in the middle of the tube bundle 7, and the cathode is covered with an insulating sleeve; the inlet and outlet sides of the cylinder 5 are insulated and sealed with a control reference electrode 3 and a monitoring reference electrode 4 , the potentiostat 14 is electrically connected to the anode, the cathode 2, the control reference electrode 3, and the monitoring reference electrode 4 through wires and cables to form the anode protection system; tube box 15, and the working medium outlet 8 is arranged on the large volume tube box 15, and the tube box on the other side of the cylinder body 5 is provided with a working medium inlet 11, and the concentrated sulfuric acid cooler and the large volume tube box 15 form a...

Embodiment 2

[0026] Embodiment 2, with reference to figure 1, a low-temperature waste heat recovery device for a concentrated sulfuric acid cooler. The concentrated sulfuric acid cooler has an anode protection system. One or several cathodes 2 connected in parallel are arranged in the middle of the tube bundle 7, and the cathode is covered with an insulating sleeve; the inlet and outlet sides of the cylinder 5 are insulated and sealed with a control reference electrode 3 and a monitoring reference electrode 4 , the potentiostat 14 is electrically connected to the anode, the cathode 2, the control reference electrode 3, and the monitoring reference electrode 4 through wires and cables to form the anode protection system; 13 communicates with the gas storage tank 16, and the working fluid outlet 8 is arranged on the gas storage tank 16, and the working fluid inlet 11 is set on the tube box on the other side of the cylinder body 5, and the concentrated sulfuric acid cooler and the gas storage...

Embodiment 3

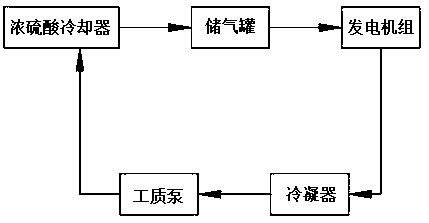

[0029] Embodiment 3, with reference to figure 2 , a power generation system composed of a chromium-nickel alloy concentrated sulfuric acid cooler and a low-temperature waste heat recovery device. The pumps are connected in turn through pipelines to form a closed loop to form a power generation system. The generator set can be a steam turbine, a screw expander or a turbogenerator set, wherein the gas storage tank mainly functions as a working fluid evaporation chamber. This cycle consists of 4 processes. The working medium enters the anode-protected concentrated sulfuric acid cooler, absorbs the low-temperature waste heat and turns it into high-temperature and high-pressure superheated steam, which is input into the gas storage tank. After the working medium steam is adjusted to a state suitable for the operation of the steam turbine, it enters the The generator set expands to do work, and then drives the generator to generate electricity, turning it into low-temperature and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com