Hydrophobic and oleophobic polyolefin material and preparation method thereof

A hydrophobic and oleophobic polyolefin technology, applied in the field of perfluorosurfactant modified polyolefin materials and its preparation, to achieve the effects of preventing fouling, reducing surface energy, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] ①. Dissolve 4.7g (39.6mmol) of thionyl chloride in 200ml of dichloromethane in a three-necked flask equipped with a stirring bar, a thermometer and a condenser, and add 5ml of dimethylformamide (DMF), then dropwise Add 10 g (26.4 mmol) of perfluorohexylacetic acid, stir well, react at 90°C for 4 hours, then distill off the solvent and excess thionyl chloride under reduced pressure to obtain 9.23 g of perfluorohexylacetyl chloride.

[0020] ②. Dissolve 2g of nano-silica in 30ml of ethanol aqueous solution, and place it in an ultrasonic generator for ultrasonic dispersion for 30 minutes; then add 12g of aminosilane coupling agent to the above mixture drop by drop, and place it on an electromagnetic stirring table to stir at a constant temperature of 80°C After 3 hours, an aminated nano-silica suspension was obtained.

[0021] ③. Dissolve 9.23 g of perfluorohexylacetyl chloride in 92 ml of dichloromethane, then gradually add it dropwise to the aminated nano-silica suspensi...

Embodiment 2

[0024] ①. Dissolve 6.3g (52.8mmol) of thionyl chloride in 200ml of dichloromethane in a three-necked flask equipped with a stirring bar, a thermometer and a condenser, and add 5ml of dimethylformamide (DMF), then dropwise Add 10 g (26.4 mmol) of perfluorohexylacetic acid, stir well, react at 90°C for 4 hours, then distill off the solvent and excess thionyl chloride under reduced pressure to obtain 9.86 g of perfluorohexylacetyl chloride.

[0025] ②. Dissolve 2g of nano-silica in 30ml of ethanol aqueous solution, and place it in an ultrasonic generator for ultrasonic dispersion for 30 minutes; then add 12g of aminosilane coupling agent to the above mixture drop by drop, and place it on an electromagnetic stirring table to stir at a constant temperature of 80°C After 3 hours, an aminated nano-silica suspension was obtained.

[0026] ③. Dissolve 9.86 g of perfluorohexylacetyl chloride in 98 ml of dichloromethane, then gradually add it dropwise to the aminated nano-silica suspensi...

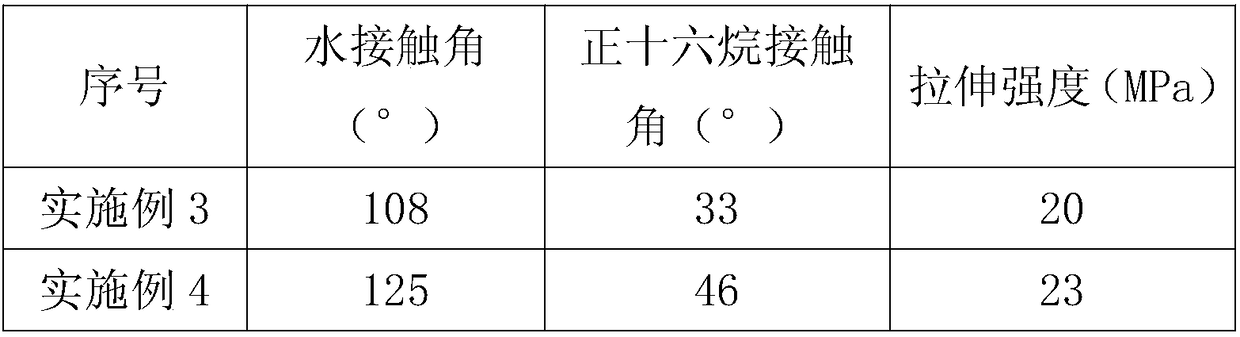

Embodiment 3

[0043] ①. Dissolve 6.3g (52.8mmol) of thionyl chloride in 200ml of dichloromethane in a three-necked flask equipped with a stirring bar, a thermometer and a condenser, and add 5ml of dimethylformamide (DMF), then dropwise Add 10 g (26.4 mmol) of perfluorohexylacetic acid, stir well, react at 90°C for 4 hours, then distill off the solvent and excess thionyl chloride under reduced pressure to obtain 9.86 g of perfluorohexylacetyl chloride.

[0044] ②. Dissolve 1g of nano-silica in 15ml of ethanol aqueous solution, and place it in an ultrasonic generator for ultrasonic dispersion for 30 minutes; then add 6g of aminosilane coupling agent to the above mixture drop by drop, and place it on an electromagnetic stirring table to stir at a constant temperature of 80°C After 3 hours, an aminated nano-silica suspension was obtained.

[0045] ③. Dissolve 9.86 g of perfluorohexylacetyl chloride in 98 ml of dichloromethane, then gradually add it dropwise to the aminated nano-silica suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com