Integrated treatment and purification system and method for industrial mariculture wastewater

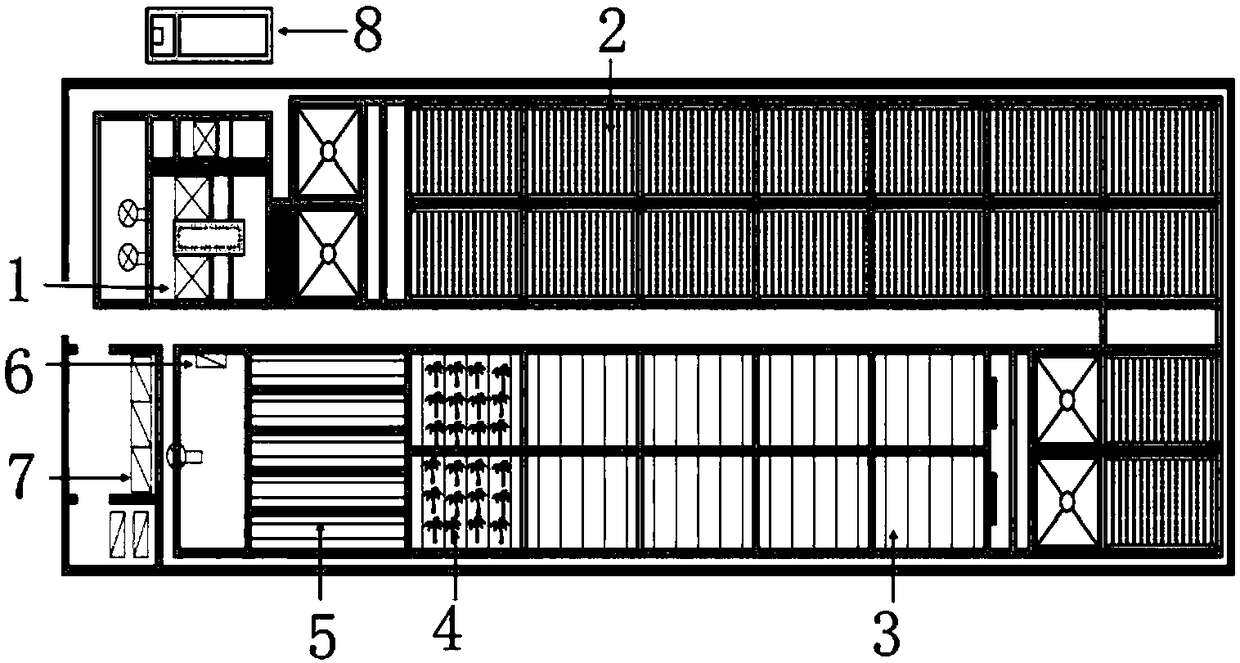

A technology of mariculture and purification system, which is applied in the direction of oxidation water/sewage treatment, seawater treatment, animal husbandry wastewater treatment, etc. It can solve the problem that it is difficult to meet the requirements of discharge water quality indicators, the volume of treated water is limited, and the area occupied is large, etc. Problems, achieve good water purification effect, diversification of treatment methods, and reduce COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The present invention was tested in a breeding enterprise in Tanggu District, Tianjin, and an indoor processing shed was built, covering mechanical filter tanks (two crawler filters), biological filler filter tanks, engineering algae culture tanks, seawater plant purification tanks, and ozone sterilization and disinfection Pool, drainage monitoring system, central control system. Build a squeeze pool (1 squeeze machine) outdoors. The waste outlet of the microfilter, and the sewage pipeline laid at the bottom of the biofilter are directly connected to the press through the waste collection pipeline. Open the valve of the waste collection pipeline, and the residual bait feces and activated sludge can be directly transferred to the outdoor press pool for treatment through the liquid level difference / water pump.

[0064] The tail water discharge of the enterprise is 1000m 3 / h, the initial concentration of ammonia nitrogen can reach up to 9mg / L, and the suspended matter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com