A kind of preparation method of food greaseproof paper

A technology for oil-proof paper and food, applied in textiles, papermaking, papermaking, packaging paper, etc., can solve the problems of changing food flavor, harmful fluorocarbons, and not easy to degrade, and achieve changes in crystallinity, improve surface hydrophobicity, and maintain chemical properties. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

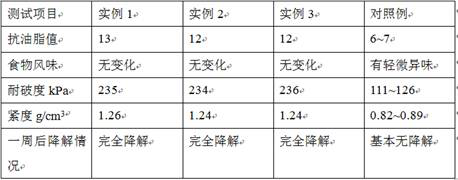

Examples

preparation example Construction

[0020] A preparation method for food greaseproof paper, comprising the steps of:

[0021] (1) According to the number of parts by mass, take 100~150 parts of bleached pulp, 0.5~1 part of filler, 0.12~0.25 parts of alkyl ketene dimer, stir and mix at 500r / min for 3~6min, then add calcium carbonate 10~20% polyacrylamide by mass, stir and mix at 1500r / min for 3~5min to obtain a stirred mixture, take the stirred mixture and add bentonite according to the mass ratio of 80~100:0.5~1, stir and mix for 10~15min, and put it in the tablet machine Copying and forming, pressing at 0.4MPa for 5-10min, drying at 110-120°C to obtain greaseproof paper base paper, for later use;

[0022] (2) According to the number of parts by mass, take 50~60 parts of cornstarch, 30~40 parts of water, 1~3 parts of α-amylase, 8~10 parts of calcium acetate, adjust the pH to 6.0~6.5, and adjust the pH to 6.0~6.5. Enzymolysis at ℃ for 20~30 min, inactivate the enzyme, and obtain the enzymatic hydrolyzate, in ter...

Embodiment 1

[0026] Bleached pulp: purchased from Mudanjiang Hengfeng Paper Industry Co., Ltd., beaten to 46°SR with a beater.

[0027] Wollastonite: purchased from Jiangxi Huajietai Mineral Fiber Technology Co., Ltd., with an average particle size of 21.71 μm and an ISO whiteness of 88.1%.

[0028] Filling material: Take wollastonite and add carboxymethyl cellulose in a mass ratio of 10:7 to mix, then add distilled water 8 times the mass of wollastonite and mix, stir and mix at 30°C for 20 minutes to obtain a filler suspension.

[0029] A preparation method for food greaseproof paper, comprising the steps of:

[0030] (1) In terms of parts by mass, take 100 parts of bleached pulp, 0.5 parts of filler, and 0.12 parts of alkyl ketene dimer, stir and mix at 500r / min for 3 minutes, and then add polyacrylamide with 10% calcium carbonate mass, Stir and mix at 1500r / min for 3 minutes to obtain a stirred mixture, take the stirred mixture and add bentonite at a mass ratio of 80:0.5, stir and mix ...

Embodiment 2

[0035] Bleached pulp: purchased from Mudanjiang Hengfeng Paper Industry Co., Ltd., beaten to 46°SR with a beater.

[0036] Wollastonite: purchased from Jiangxi Huajietai Mineral Fiber Technology Co., Ltd., with an average particle size of 21.71 μm and an ISO whiteness of 88.1%.

[0037] Filling material: Take wollastonite and add carboxymethyl cellulose in a mass ratio of 10:7 to mix, then add distilled water 10 times the mass of wollastonite and mix, stir and mix at 40°C for 30 minutes to obtain a filler suspension.

[0038] A preparation method for food greaseproof paper, comprising the steps of:

[0039] (1) In terms of parts by mass, take 150 parts of bleached pulp, 1 part of filler, and 0.25 parts of alkyl ketene dimer, stir and mix at 500r / min for 6 minutes, and then add polyacrylamide with 20% calcium carbonate mass, Stir and mix at 1500r / min for 5min to obtain a stirred mixture, take the stirred mixture and add bentonite at a mass ratio of 100:1, stir and mix for 15mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com