Sheet material etching device

An etching device and sheet technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of affecting the encapsulation sheet etching effect and encapsulation effect, affecting the encapsulation effect of organic light-emitting devices, and hindering the contact between the agent and the encapsulation sheet. and other problems, to achieve the effect of excellent etching effect, improved safety and reliability, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

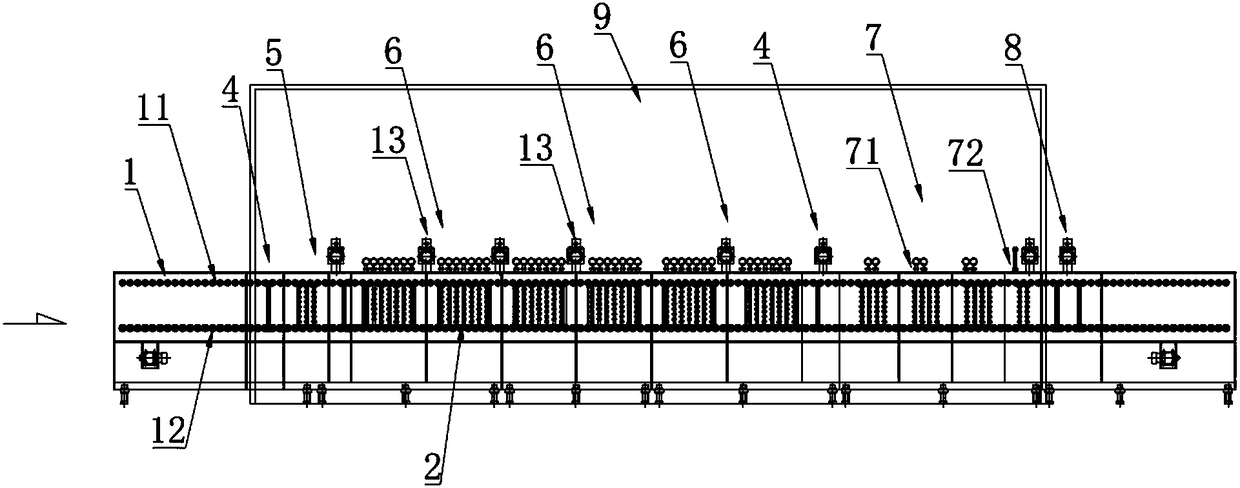

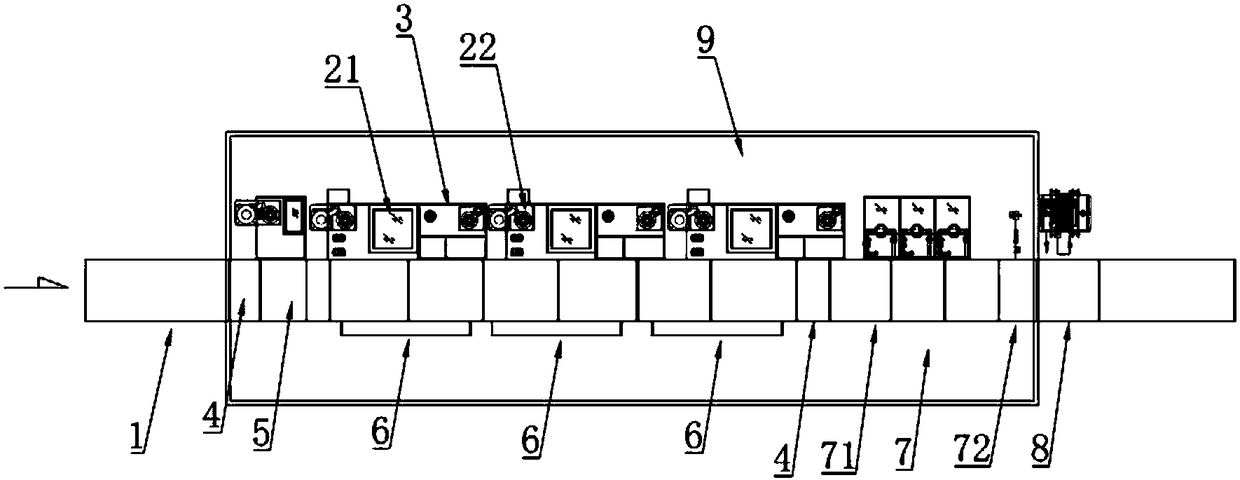

[0046] This embodiment provides a sheet etching device, such as figure 1 and figure 2 As shown, a conveying assembly 1 and a spraying assembly 2 are included. in,

[0047] The conveying assembly 1 is used to convey the sheet along a first direction, and the plane where the sheet is located is perpendicular to the horizontal plane. Specifically, the first direction refers to figure 1 The direction of the line shown in or the conveying direction of the conveying assembly, that is, the sheet moves along the direction of the line in an upright state perpendicular to the horizontal plane.

[0048] The spray assembly 2 is arranged on at least one side of the sheet, and is used for spraying the treatment liquid on the surface of the sheet. Specifically, the spray assembly 2 may be arranged on only one side of the sheet along the line direction, or may be arranged on both sides of the sheet along the line direction, and the setting may be determined according to actual etching re...

Embodiment approach

[0066] As a preferred embodiment, the sheet etching device further includes a filter element 3 . The filter element 3 is arranged vertically below the sheet and connected to the liquid storage element 21 for collecting and filtering the treatment liquid flowing through the sheet, and the filtered treatment liquid flows back into the liquid storage element 21 . In this way, the recycling of the treatment liquid is realized, the utilization rate of the treatment liquid is significantly improved, and the cost of the treatment liquid is saved for the sheet material etching device.

[0067] In this embodiment, the sheet etching device further includes an air curtain wind cutting unit 4 , an acid washing wind cutting unit 5 , an etching unit 6 , a water washing unit 7 and an air knife drying unit 8 arranged in sequence in the first direction.

[0068] Among them, the air curtain wind cutting unit 4 , the pickling wind cutting unit 5 and the air knife drying unit 8 mainly dry the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com