Method for preparing double-enzyme enzymatic hydrolysis octenyl succinic anhydride modified starch ester

A technology of octenyl succinic anhydride and octenyl succinate, applied in the field of macromolecular emulsifier preparation, can solve the problems of unsatisfactory emulsification performance, high price, unsatisfactory emulsification stability and the like, and achieves increased emulsification Stability, enhancing emulsifying ability, reducing the effect of product molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

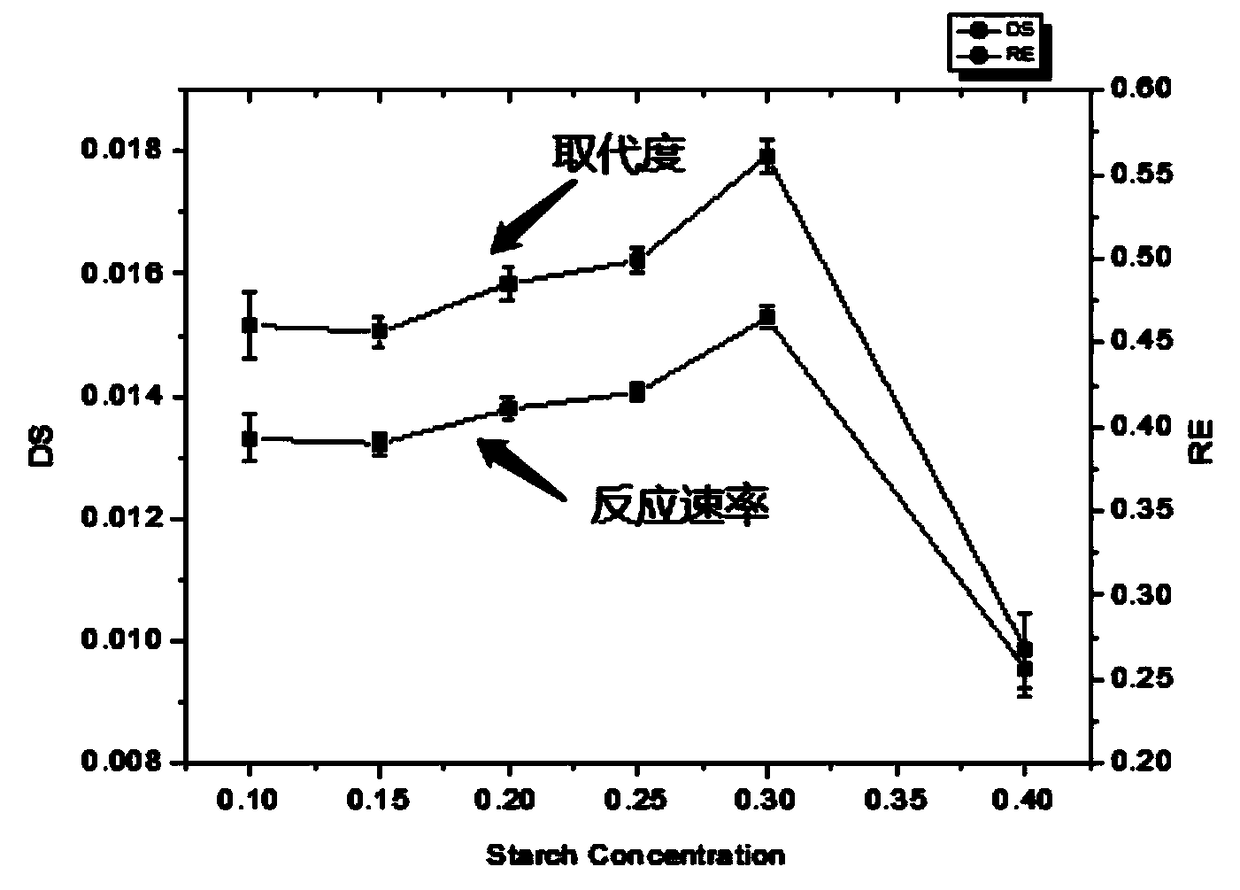

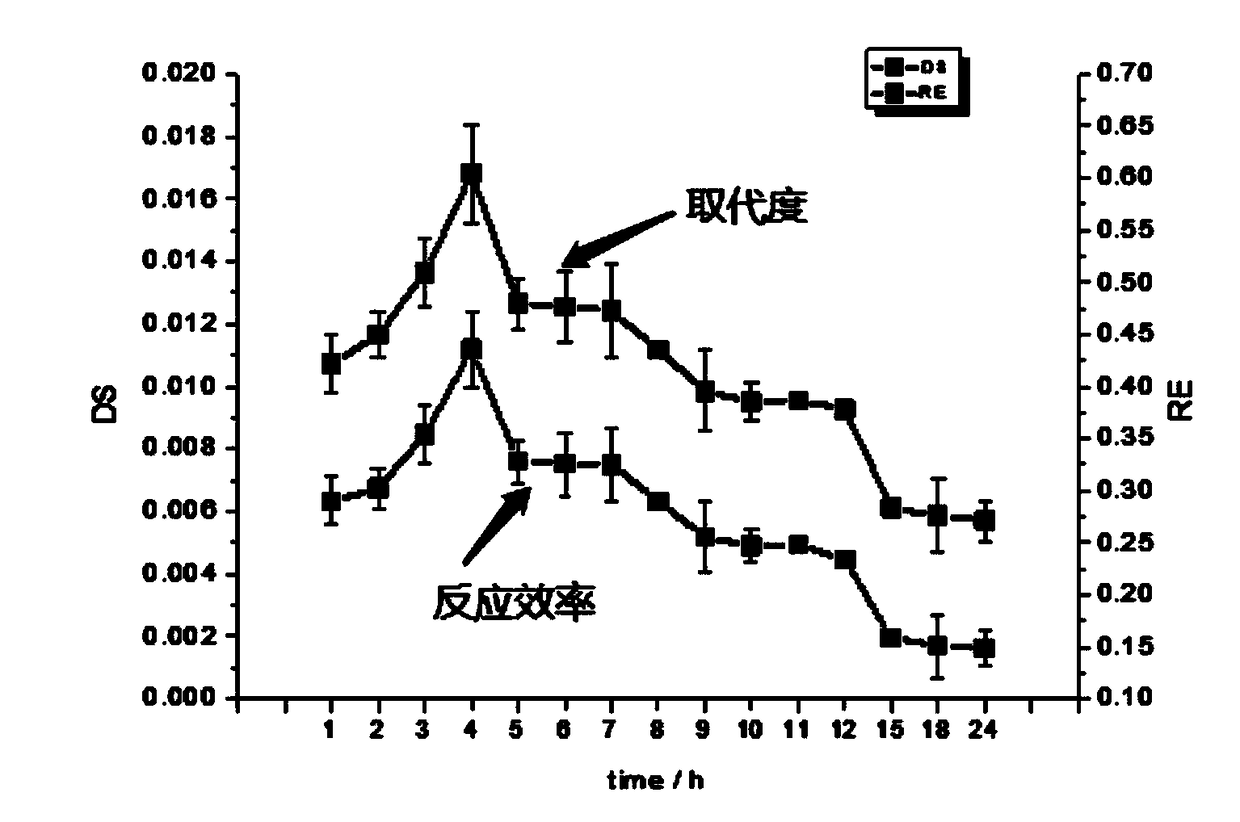

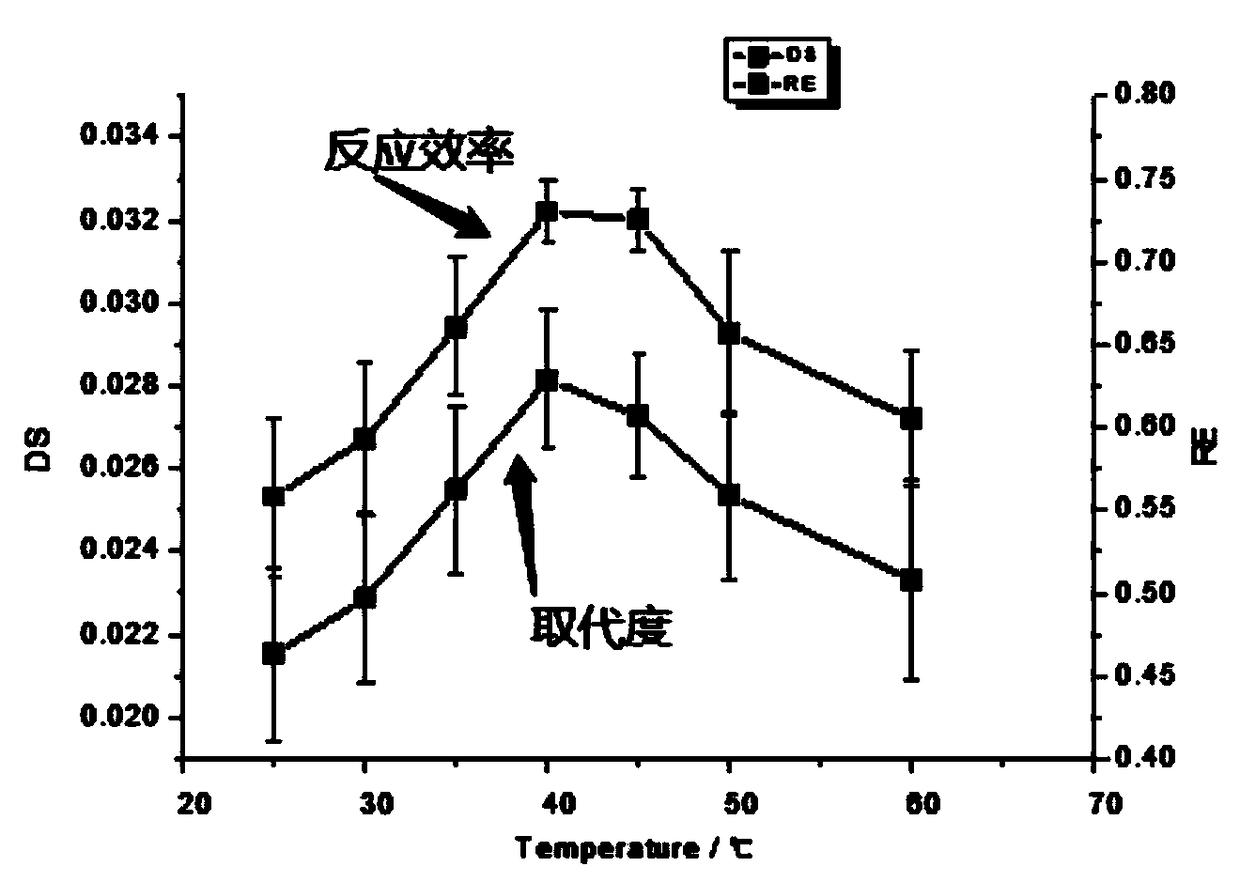

[0032] Embodiment 1: the preparation of octenyl succinic anhydride starch ester

[0033] Prepare a certain concentration (w / v) of starch milk and place it in a beaker, adjust the pH of the starch milk to a certain range, and after mixing, transfer the starch to a constant temperature water bath at a certain temperature, at a stirring rate of 2000r / min Slowly and uniformly add octenyl succinic anhydride diluted in 95% ethanol solution to the starch milk within 0.5 hour. Use 2% NaOH solution to control the pH of the system and keep it within a certain range. After continuing the reaction for a certain period of time, the pH of the system was adjusted to 6.5 with 2% HCl. Then transfer the starch milk to the Buchner funnel, wash it twice with 75% ethanol by suction filtration, then centrifuge twice with distilled water, dry it in an oven at 40°C after dehydration, and finally grind the dried esterified starch Sieve to obtain the finished product of starch octenyl succinate.

[...

Embodiment 2

[0049] Embodiment 2: the mensuration of degree of substitution of starch octenyl succinate

[0050] The specific method is as follows:

[0051] Accurately weigh 1.5g-2g canna starch octenyl succinate with an electronic balance, dissolve it in 50mL 95% isopropanol solution, place it on a magnetic stirrer and stir for 10min, then add 15mL 2.0mol / L hydrochloric acid-isopropyl alcohol Alcohol solution, continue magnetic stirring for 30 min. Then the solution was transferred to a Buchner funnel for dehydration, and washed several times with 90% isopropanol solution until no chloride ions were detected with 0.1mol / L silver nitrate. Then transfer the solid sample into a 250mL Erlenmeyer flask, add 100mL of distilled water, heat in a boiling water bath for 20min, then immediately add 2 drops of phenolphthalein and shake well, titrate with 0.1mol / L NaOH while hot until pink. The calculation formula of product substitution degree is as follows:

[0052]

[0053] In the formula: 0....

Embodiment 3

[0054] Example 3: Enzymatic hydrolysis of starch octenyl succinate with alpha amylase only

[0055] 1. The octenyl succinic anhydride starch ester prepared in Example 1 was prepared into a suspension with a mass concentration of 10% with a buffer solution, and kept stirring in a 40° C. water bath.

[0056] ②Dissolve a-amylase with acetic acid-sodium acetate buffer solution, refrigerate and centrifuge at 4000r / min for 30min. Take the supernatant and set aside.

[0057] ③ Add a-amylases with enzyme activities of 0.7, 3.5, 6.6, and 19.8 U / g to the suspension of starch octenyl succinate, and keep the temperature in a water bath at a certain reaction temperature and pH value of 4.5. Oscillation response for a certain time.

[0058] ④ Adjust the pH of the reaction system to 2 to inactivate the enzyme.

[0059] Figure 5 After the emulsion was prepared by hydrolyzing OSA starch with α-amylase only, the emulsification rate of the emulsion was accelerated after 30 days of storage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com