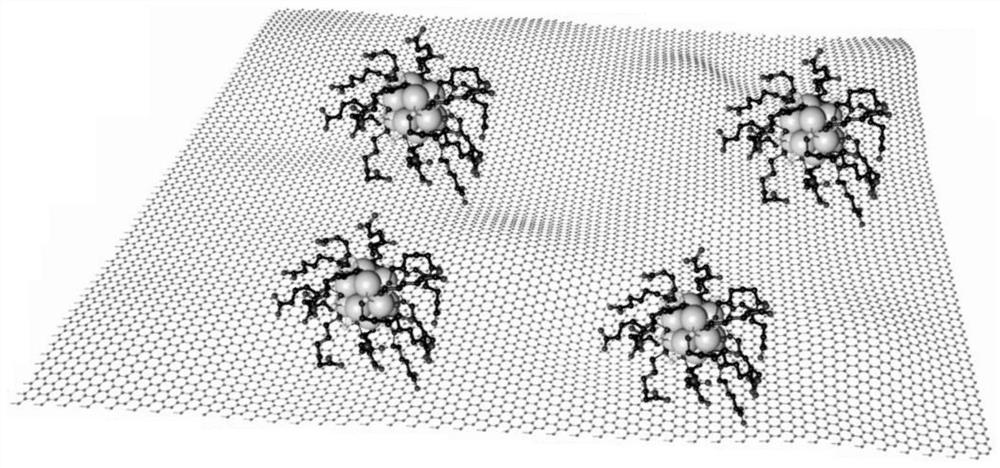

A kind of preparation method of gold cluster/graphene composite catalytic membrane

A technology of graphene composite and gold clusters, which is applied in the field of catalytic membranes, can solve the problems such as difficult recovery of gold clusters, and achieve the effects of high catalytic activity, avoiding agglomeration, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

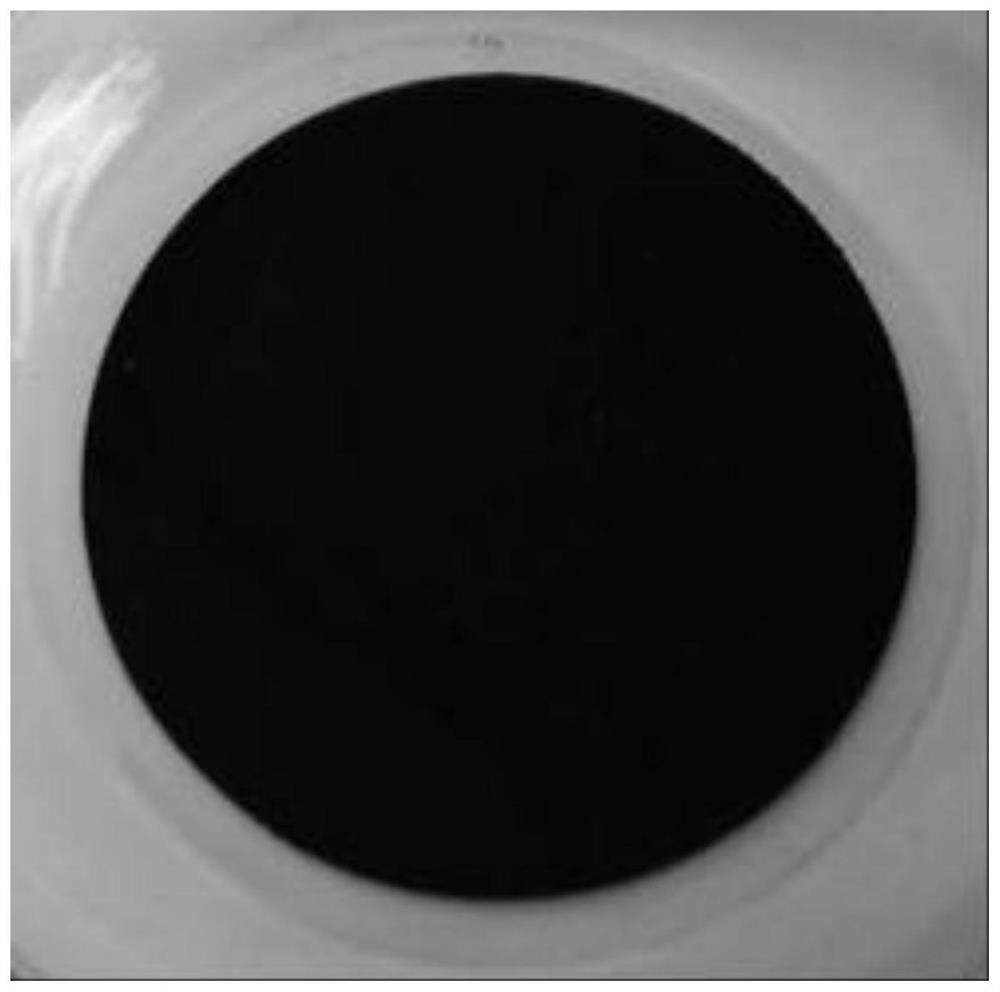

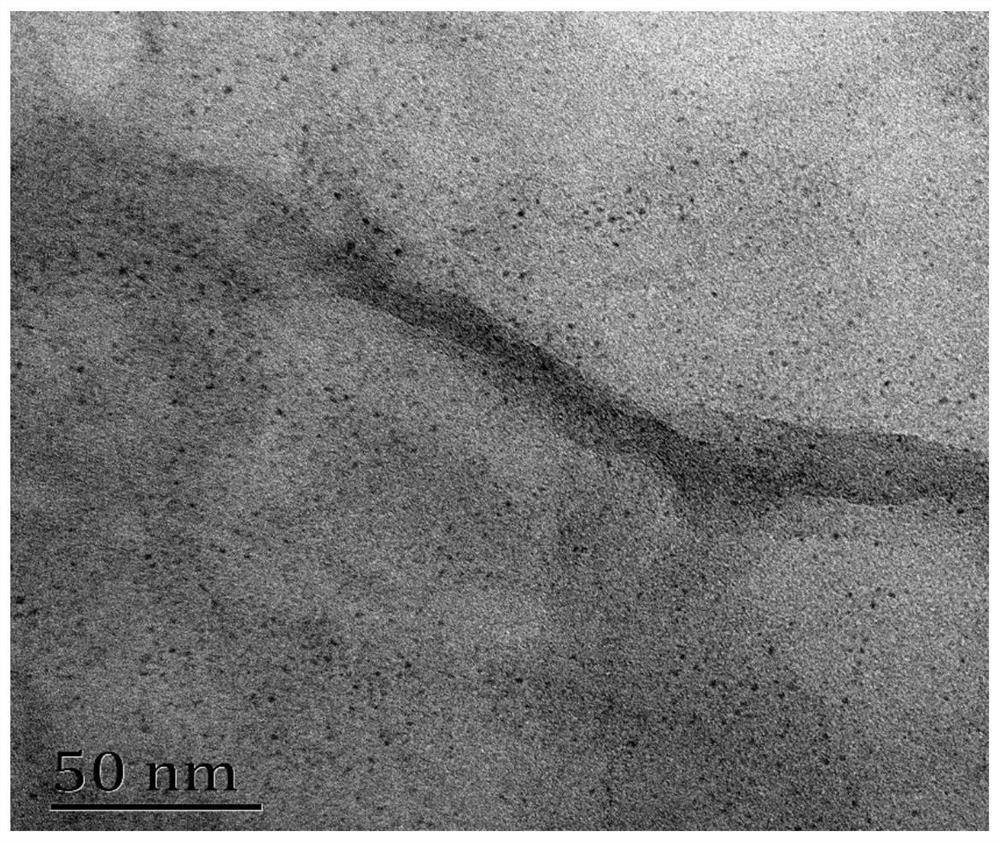

Embodiment 1

[0026] Weigh 50 mg of graphene oxide into a beaker with an analytical balance, add 25 mL of deionized water and use the probe to ultrasonicate for 15 min to make it evenly dispersed to obtain mixed solution A, pour A into a polytetrafluoroethylene reactor and water at 180 ° C After heating for 5 h, the obtained rGO was rod-shaped. After freeze-drying, 5 mg of rGO was added to 10 mL of thiol ligand-protected gold cluster solution (1 mM) and 10 mL of ultrapure water. After sonication for 45 min, a uniformly dispersed mixture B was obtained. After the membrane, the excess material was washed with 150 mL of deionized water to form a homogeneous composite catalytic membrane. Using 0.2mM p-nitrophenol (4-NP) solution at a flow rate of 1mL / min for 2h to reach adsorption saturation, 0.5mM, 1.0mM and 1.5mM p-nitrophenol (4-NP) were degraded in turn. solution, the degradation effect is 100%, 100%, 100% respectively.

Embodiment 2

[0028] Weigh 50 mg of graphene oxide into a beaker with an analytical balance, add 25 mL of deionized water and use the probe to ultrasonicate for 15 min to make it evenly dispersed to obtain mixed solution A, pour A into a polytetrafluoroethylene reactor and water at 180 ° C After heating for 5 h, the obtained rGO was rod-shaped. After freeze-drying, 5 mg of rGO was added to 5 mL of thiol ligand-protected gold cluster solution (1 mM) and 15 mL of ultrapure water. After sonication for 45 min, a uniformly dispersed mixture B was obtained. After the membrane, the excess material was washed with 150 mL of deionized water to form a homogeneous composite catalytic membrane. The 0.2 mM p-nitrophenol (4-NP) solution was used to pass through the membrane for 2 h at a flow rate of 1 mL / min to reach adsorption saturation, and then the 0.5 mM, 1.0 mM and 1.5 mM 4-NP solutions were degraded in turn. The degradation effects were as follows: 100%, 96.1%, 62.1%.

Embodiment 3

[0030] Weigh 50 mg of graphene oxide into a beaker with an analytical balance, add 25 mL of deionized water and use the probe to ultrasonicate for 15 min to make it evenly dispersed to obtain mixed solution A, pour A into a polytetrafluoroethylene reactor and water at 180 ° C After heating for 5 h, the obtained rGO was rod-shaped. After freeze-drying, 5 mg of rGO was added with 20 mL of thiol ligand-protected gold cluster solution (1 mM). After sonication for 45 min, a uniformly dispersed mixed solution B was obtained. A homogeneous composite catalytic membrane is formed after the ionized water washes the excess material. The 0.2 mM p-nitrophenol (4-NP) solution was used to pass through the membrane for 2 h at a flow rate of 1 mL / min to reach adsorption saturation, and then 0.5 mM, 1.0 mM and 1.5 mM 4-NP were degraded in turn, and the degradation effects were 100 %, 100%, 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com