A kind of preparation method of machine-woven carpet without back glue technology

A carpet and process technology, which is applied in the field of preparation of woven carpets without adhesive technology, can solve the problems of increased carpet production cost, insufficient pull-out strength of pile yarn, and limited production speed, so as to omit the adhesive process, Enhance shape retention and dimensional stability, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a preparation method of a machine-woven carpet without back glue technology. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

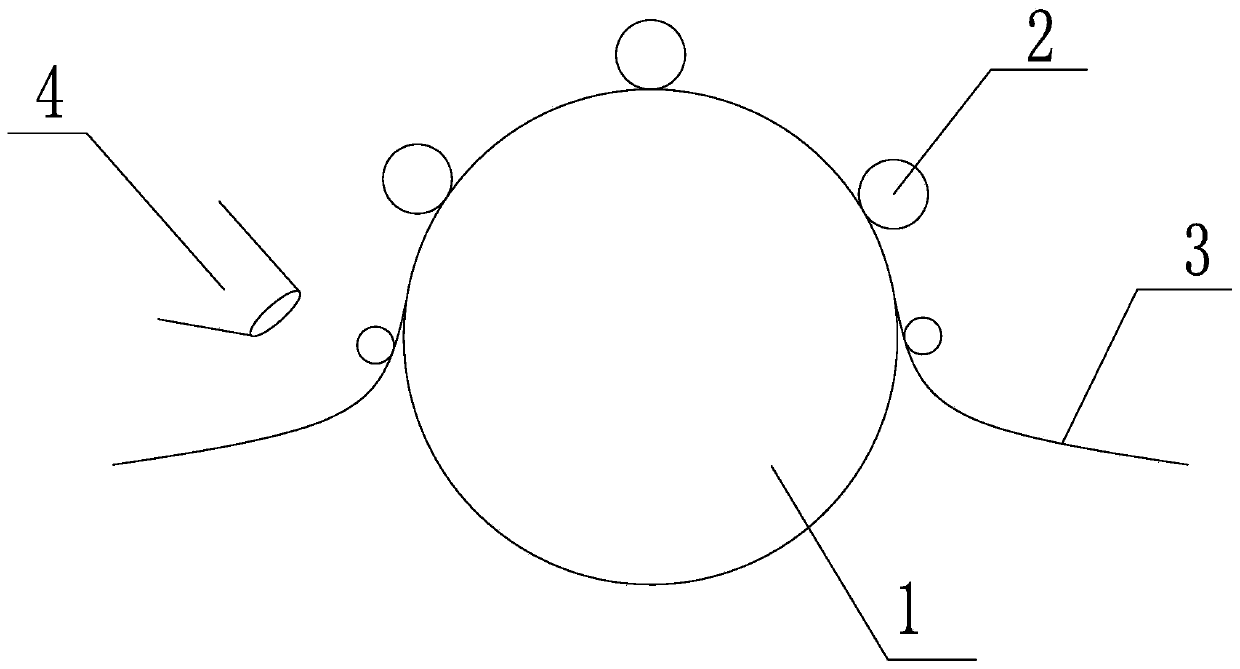

[0030] The invention provides a method for preparing a machine-woven carpet without adhesive backing technology. The carpet includes base cloth, pile yarn, weft yarn and warp yarn, and the weft yarn includes a pile weft yarn and a pile weft yarn without a pile. The ratio of head weft yarn to non-pile weft yarn is 1:1-1:2, and the pile yarn is a fiber filament yarn, staple yarn or staple fiber blended yarn made of cationic dyeable acrylic fiber that meets the needs of carpets. The weft yarn of the hanging pile is a composite yarn, and the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com