Preparation method of latex-free woven carpet

A carpet and latex technology, applied in carpets, textiles, fabrics, etc., can solve the problems of difficult reuse, limited production speed, long process flow, etc., to facilitate melt flow and bonding, enhance capillary infiltration, melt good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a method for preparing a latex-free woven carpet. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

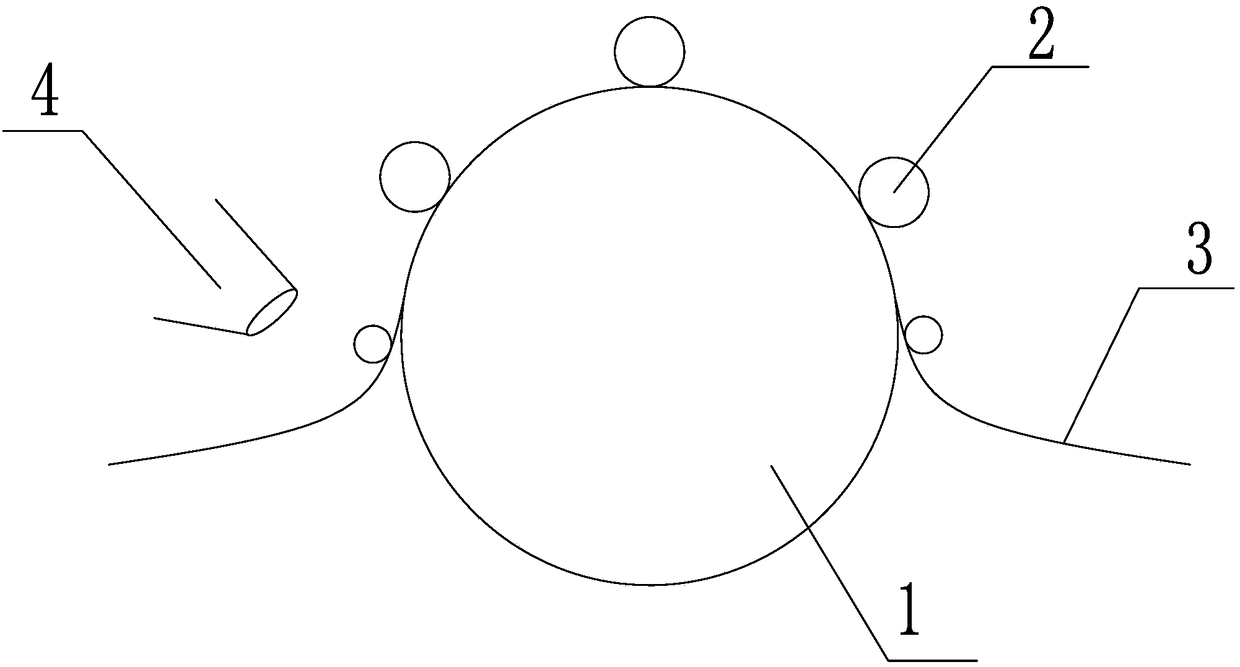

[0025] The invention provides a method for preparing a latex-free woven carpet. The carpet includes a base cloth, a pile yarn, a weft yarn and a warp yarn, and the weft yarn includes a pile weft yarn and a non-pile weft yarn, and the pile weft yarn and the pile weft yarn The ratio of non-pile weft yarns is 1:1-1:2, which reduces the amount of hot-melt fibers and reduces production costs on the premise of ensuring the pull-out force of pile tufts. The weft yarn of the hanging pile is a composite yarn, and the composite yarn is composed of a core yarn and a covering layer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com