Nitrogen flow jetting type hard cutting machining device and cutting method

A hard cutting and processing device technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as unsatisfactory use requirements, superhard tool chipping, etc., to increase service life and improve fatigue resistance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

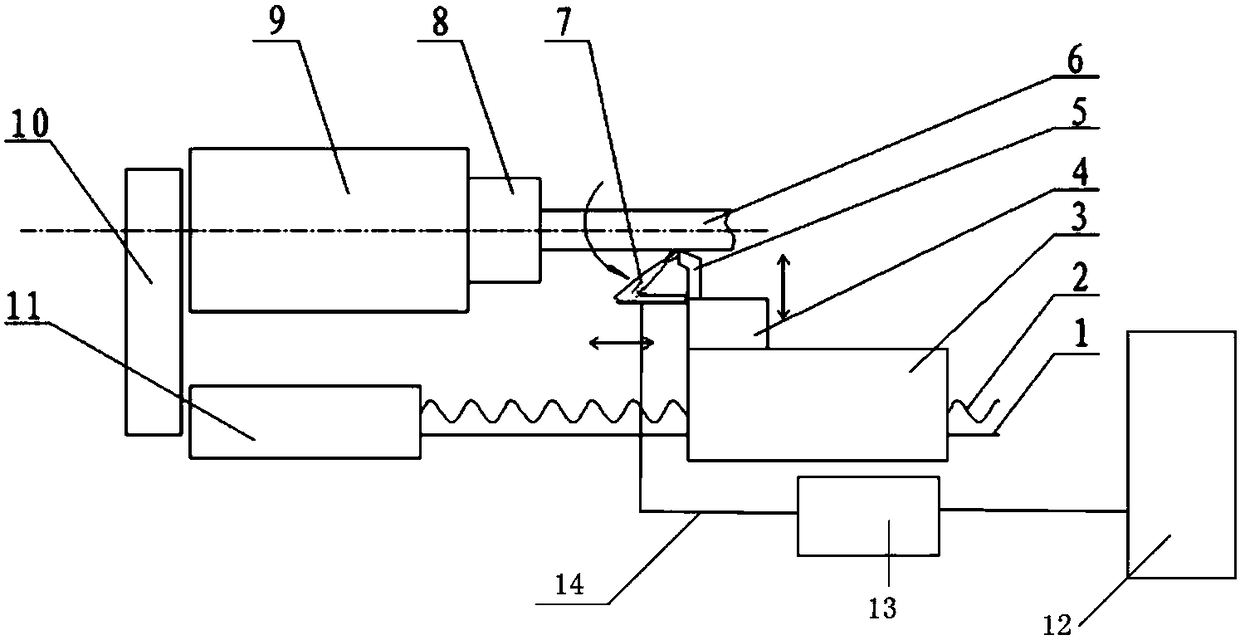

[0028] Such as Figure 1-4 As shown, this embodiment provides a nitrogen jet hard cutting device, including a cutting machine tool, and also includes a nitrogen jet device used in conjunction with the cutting machine tool, wherein,

[0029] The cutting machine tool includes an exchange gear box 10, a headstock 9 and a feed box 11 arranged in parallel, and the headstock 9 and the feed box 11 are respectively connected with the transmission of the exchange gear box 10. The other end is provided with a chuck 8 for clamping and fixing the hardened workpiece 6 to be cut and processed. During the machining process, the chuck 8 drives the hardened workpiece 6 to rotate during the rotation of the main shaft inside the headstock 9 ;

[0030] The other end of the feed box 11 is horizontally provided with a polished rod 1 and a screw mandrel 2, and also includes a sliding crate 3 capable of linear translation along the polished rod 1 driven by the screw rod 2, the sliding crate 3 is pro...

Embodiment 2

[0038] This embodiment provides a nitrogen jet hard cutting method, in which the superhard tool 5 is used to cut the hardened workpiece 6, and at the same time, the normal temperature nitrogen separated from the air by the nitrogen generator 12 is controlled by the nitrogen control system 13 The high-pressure nitrogen nozzle of the nitrogen jetting device is sprayed onto the processed surface of the hardened workpiece 6 at high speed, and nitrogen is used to cool down the superhard tool 5 and the hardened workpiece 6 while cutting, and to isolate the air for anti-oxidation treatment.

[0039] The present invention uses the normal-temperature safe and clean nitrogen separated from the air by the hollow nitrogen generator 12 as the cooling medium, so that the cutting fluid is not used in the cutting process, and the water can play the role of cleaning, lubricating and cooling, and it not only avoids cutting fluid It pollutes the environment and avoids the cracking of the superhar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com