Graphene and silicon composite and preparation method thereof

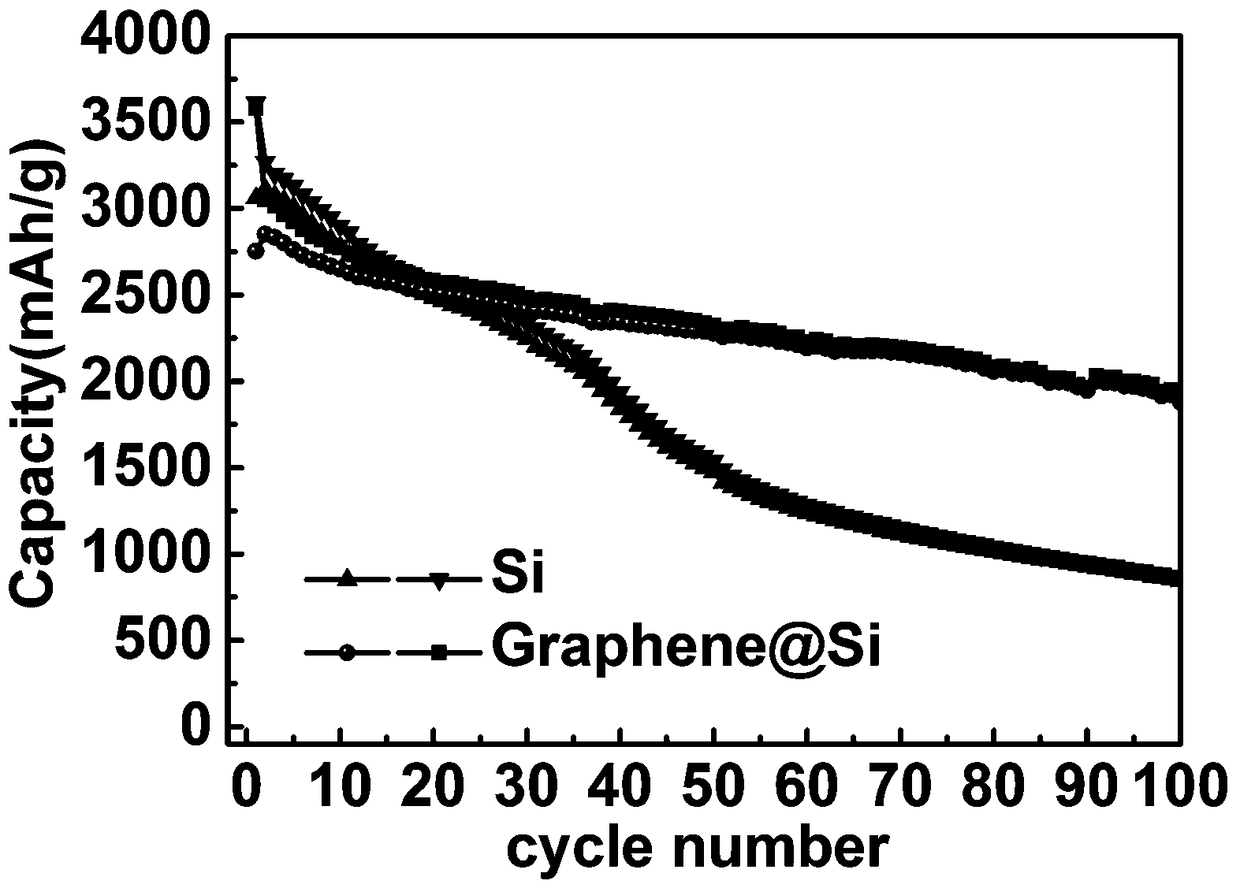

A technology of silicon composite materials and composite materials, applied in the direction of nanotechnology for materials and surface science, active material electrodes, electrical components, etc., can solve the problems of high raw material cost, silicon shedding, fast capacity decay, etc., and achieve the preparation process Simple and easy to implement, promote further development, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of graphene@silicon composite material, comprising the following steps:

[0039] S1: Nano-silicon pretreatment, after nano-silicon is evenly dispersed in the mixture of ethanol and deionized water, hydrofluoric acid is added to bring hydrogen on the surface of nano-silicon; the particle size of nano-silicon is 5-150 nm, and ethanol is 30~40ml, 40~60ml for deionized water, 50~70ml for hydrofluoric acid.

[0040] S2: Electroless deposition of metal nickel, adding the nano-silicon pretreated in step S1 to the chemical plating solution, dip-plating at a constant temperature of 30-100°C for 5-15 minutes, so that it is coated with a layer of metal nickel; wherein, chemical The plating solution is composed of nickel salt, complexing agent, sodium hypophosphite, citric acid and surfactant, and the pH of the solution is adjusted to 8~10 by ammonia water. The nickel salt is one or more of nickel chloride, nickel sulfate, nickel nitrate and nickel acetate. T...

Embodiment 1

[0045] S1: Evenly disperse nano-silicon in a mixture of 35ml ethanol and 50ml water, then add 30 ml hydrofluoric acid to treat the surface of nano-silicon with hydrogen;

[0046] S2: Prepare an electroless plating solution containing 0.1mol / L nickel chloride, 0.56mol / L ammonium chloride, 0.03mol / L citric acid, 0.3mol / L sodium hypophosphite, 0.01mol / L sodium dodecyl sulfate, Adjust the pH to 8 with ammonia water, then add the pretreated nano-silicon into the electroless plating solution, and dip-plat at a constant temperature of 60 °C for 5 min;

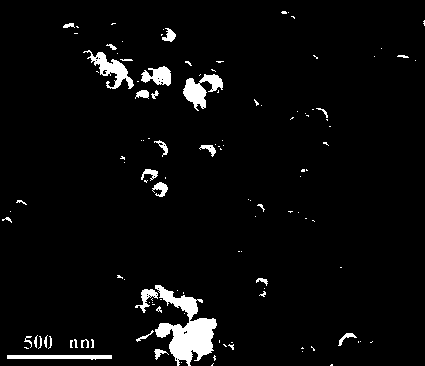

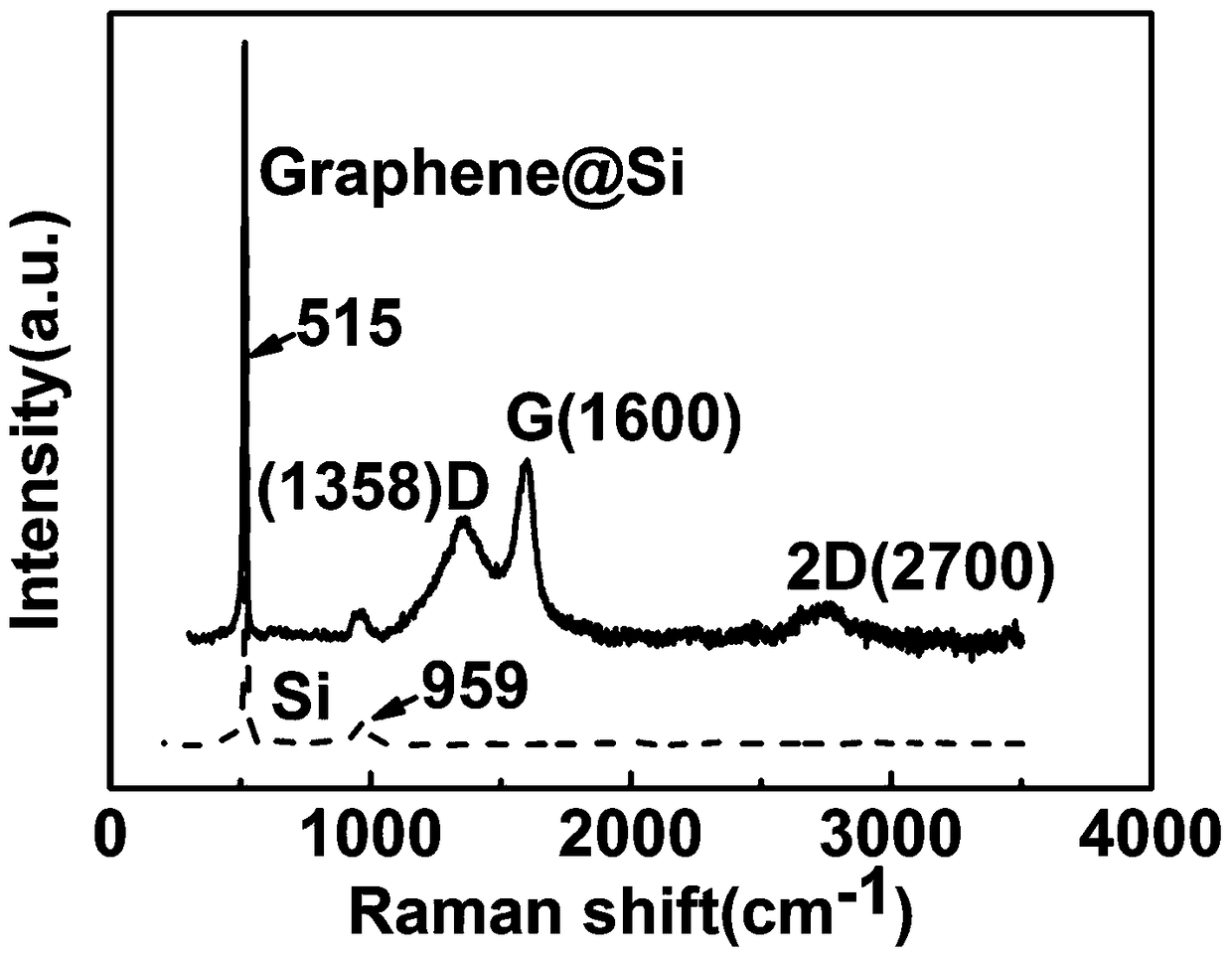

[0047] S3: Add the nickel-coated nano-silicon obtained in step S2 into 38 ml of triethylene glycol, stir evenly, and then add 0.25 ml of a 50% sodium hydroxide solution, and continue stirring at 185 ° C for 8 hours. After the obtained product is filtered, washed, and dried, the temperature is raised to 450°C in a quartz tube filled with an inert atmosphere, and calcined for 1 hour to obtain a graphene / nickel / @nano-silicon composite ma...

Embodiment 2

[0050] S1: Evenly disperse nano-silicon in a mixture of 50ml ethanol and 50ml water, then add 50ml hydrofluoric acid to treat the surface of nano-silicon with hydrogen;

[0051] S2: Prepare an electroless plating solution containing 0.15mol / L nickel chloride, 0.56mol / L ammonium chloride, 0.03mol / L citric acid, 0.3mol / L sodium hypophosphite, 0.01mol / L sodium dodecyl sulfate, Adjust the pH to 8.5 with ammonia water, then add the pretreated nano-silicon into the electroless plating solution, and dip-plat for 10 min at a constant temperature of 50°C;

[0052] S3: Add the nickel-coated nano-silicon obtained in step S2 into 60 ml of triethylene glycol, stir evenly, then add 0.25 ml of sodium hydroxide solution with a mass fraction of 50%, and continue stirring at 200 ° C for 8 hours. After the obtained product is filtered, washed and dried, the temperature is raised to 400°C in a quartz tube filled with an inert atmosphere, and calcined for 3 hours to obtain a graphene / nickel / @nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com