Crease-resistant non-ironing type suit fabric

A wrinkle-free ironing, fabric technology, applied in the field of suit fabrics, can solve the problems of high equipment requirements, high processing costs, complex processes, etc., and achieve the effects of low shrinkage rate, good texture and low shrinkage rate after washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

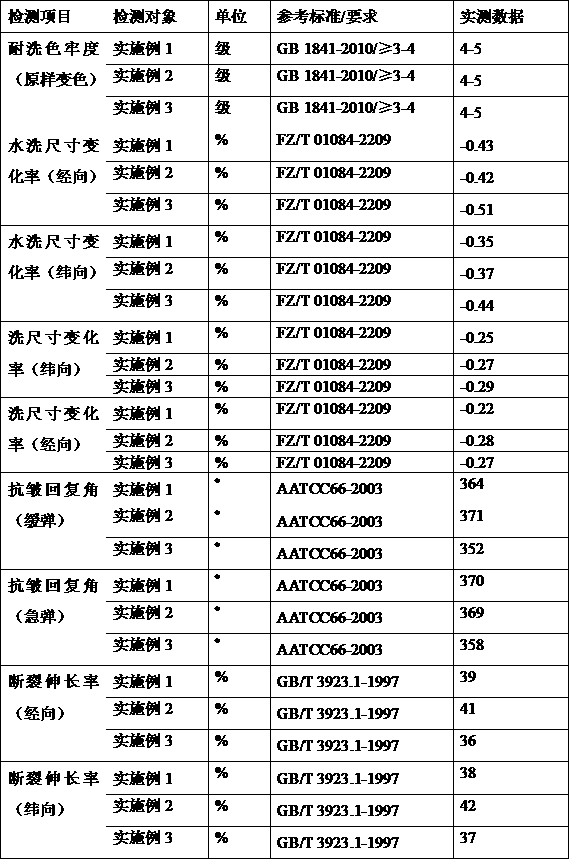

Examples

Embodiment 1

[0032] An anti-wrinkle liquid A, in parts by mass, whose preparation method is as follows:

[0033] Add 8 parts of urea, 0.01 part of dodecyltrimethylammonium bromide, and 40 parts of water into the reactor, dissolve evenly, and then add 2 parts of low hydrogen-containing silicone oil (viscosity of 20mm 2 / s, the mass percentage of active hydrogen is 0.2%), after 1200r / min high-speed dispersion and emulsification, heat to 70°C for 1h to obtain a modified urea solution; adjust the pH to 5-6, temperature 60°C, add to 20 parts Add half of the modified urea solution dropwise to the 40% glyoxal aqueous solution, adjust the pH to 4-5 after 0.5h of the dropwise addition, then add the other half of the modified urea solution dropwise for 0.5h after the dropwise addition, and finally adjust The pH of the system is 4-5, and the anti-wrinkle lotion A is obtained.

Embodiment 2

[0035] An anti-wrinkle liquid B, in parts by mass, whose preparation method is as follows:

[0036] Add 18 parts of urea, 0.05 parts of octadecyltrimethylammonium bromide, and 50 parts of water into the reactor, dissolve evenly, and then add 5 parts of low hydrogen-containing silicone oil (viscosity of 15mm 2 / s, the mass percentage of active hydrogen is 0.1%), after 800r / min high-speed dispersion and emulsification, heated to 50°C for 2h to obtain a modified urea solution; adjust the pH to 5-6, temperature 40°C, to 25 parts Add half of the modified urea solution dropwise to the 40% glyoxal aqueous solution, adjust the pH to 4-5 after 1 hour, then add the other half of the modified urea solution drop by drop for 1 hour, and finally adjust the pH of the system 4-5, the anti-wrinkle lotion B is obtained.

Embodiment 3

[0038] An anti-wrinkle liquid C, in parts by mass, whose preparation method is as follows:

[0039] Add 11 parts of urea, 0.02 parts of dodecyltrimethylammonium chloride, and 46 parts of water into the reactor, dissolve evenly, and then add 4 parts of low hydrogen-containing silicone oil (viscosity of 25mm 2 / s, the mass percentage of active hydrogen is 0.3%), after 900r / min high-speed dispersion and emulsification, heated to 60°C and reacted for 1.5h to obtain a modified urea solution; adjust the pH to 5-6, temperature 54°C, to 22 Add half of the modified urea solution dropwise in 40% glyoxal aqueous solution, adjust the pH to 4-5 after 0.8h dropwise addition, then add the other half of the modified urea solution dropwise for 0.8h, and finally Adjust the pH of the system to 4-5 to obtain the anti-wrinkle lotion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com