A method for continuously and rapidly preparing bn coatings on the surface of SIC fibers

A fiber surface and coating technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of easy decomposition of BN, uneven coating, and inability to obtain stable crystal form of BN, so as to avoid The effect of surface crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

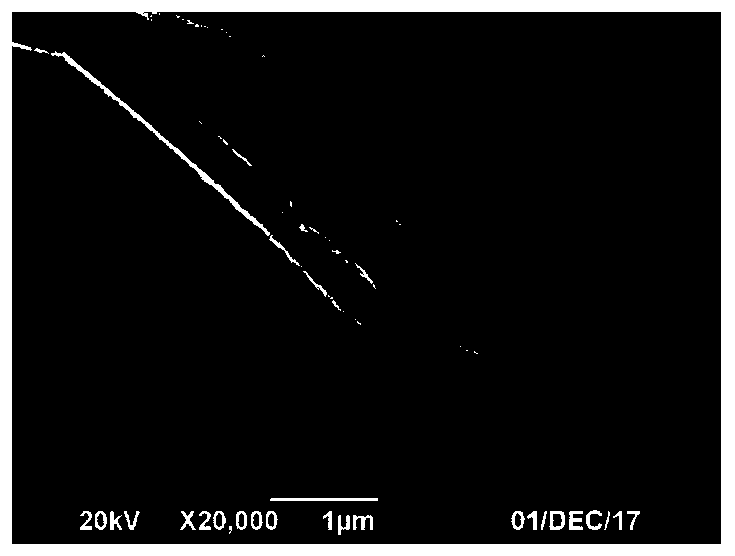

Embodiment 1

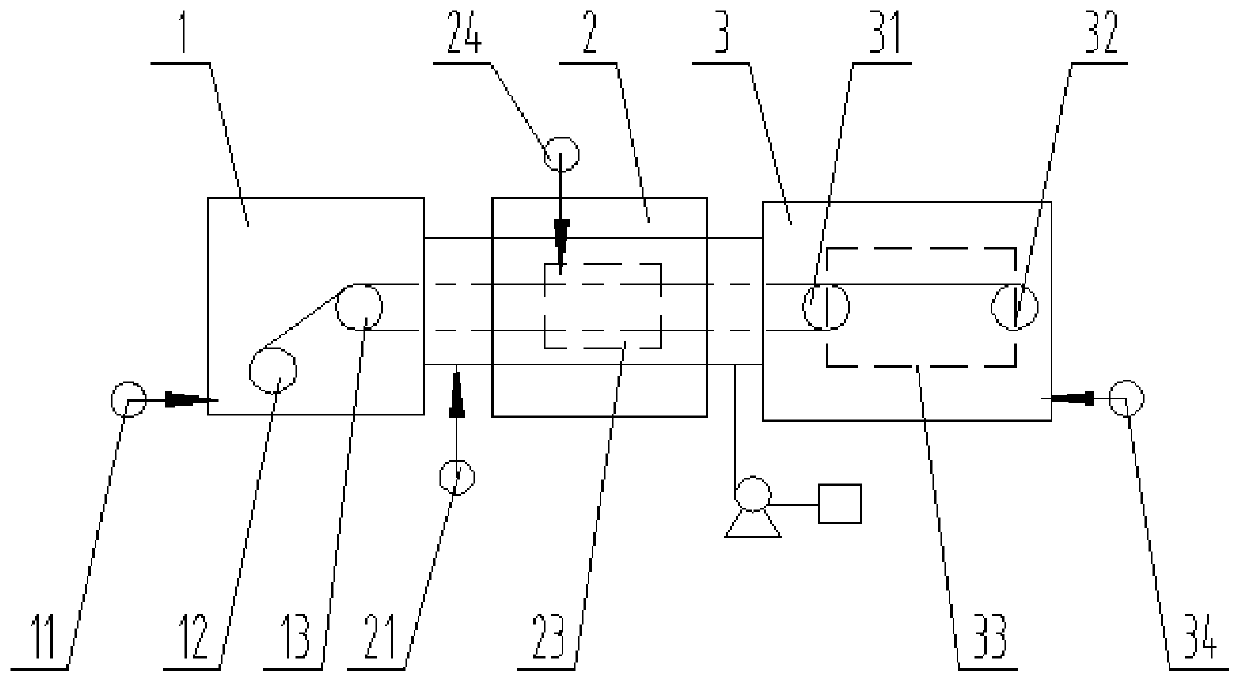

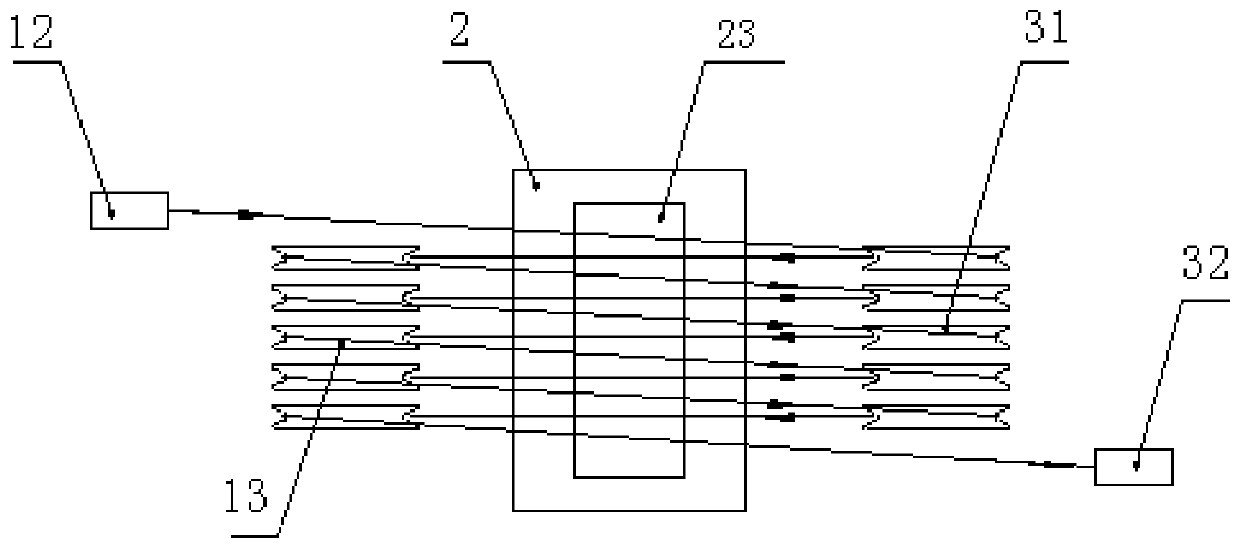

[0065] First, the vapor deposition device 2 and the heat treatment device 3 are evacuated through the vacuum system. Since the wire releasing device 1 and the vapor deposition device 2 are in a connected state, they will also be evacuated. The gas port C11 is fed with argon gas, and the gas inlet F34 of the heat treatment device 3 is fed with nitrogen gas, and the gas replacement is performed 3 times.

[0066] After the gas replacement is completed, the deposition stage is carried out. The air inlet C11 of the wire feeding device 1 continues to be fed with argon gas, and the flow rate of the argon gas is controlled to be 1.0 L / min. The nitrogen gas is continuously fed into the air inlet F34 of the heat treatment device 3, and the nitrogen gas The flow rate is 1.0L / min.

[0067] BI used in the deposition process 3 and NH 3 As the source gas, H 2 As diluent gas, NH 3 The deposition furnace is carried out from the second gas inlet 21 of the vapor deposition device 2, BI 3 Af...

Embodiment 2

[0071] Vacuumize the vapor deposition device 2 and the heat treatment device 3 through the vacuum system first, because the wire releasing device 1 and the vapor deposition device 2 are in a connected state, they will also be vacuumed, and then respectively from the air inlet C11 of the wire releasing device 1 Argon gas was introduced, and nitrogen gas was introduced from the gas inlet F34 of the heat treatment device 3, and the gas replacement was performed 3 times.

[0072] After the gas replacement is completed, the deposition stage is carried out. The air inlet C11 of the wire feeding device 1 continues to be fed with argon gas, and the flow rate of the argon gas is controlled to be 4.0 L / min. The nitrogen gas is continuously fed into the air inlet F34 of the heat treatment device 3, and the nitrogen gas The flow rate is 1.0L / min.

[0073] BCl was used in the deposition process 3 and NH 3 As the source gas, H 2 As diluent gas, NH 3 Carry out in the deposition furnace f...

Embodiment 3

[0077] First, the vapor deposition device 2 and the heat treatment device 3 are evacuated through the vacuum system. Since the wire releasing device 1 and the vapor deposition device 2 are in a connected state, they will also be evacuated. The gas port C11 is fed with argon gas, and the gas inlet F34 of the heat treatment device 3 is fed with nitrogen gas, and the gas replacement is performed 3 times.

[0078] After the gas replacement is completed, the deposition stage is carried out. The air inlet C11 of the wire feeding device 1 continues to be fed with argon gas, and the flow rate of the argon gas is controlled to be 10.0L / min. The nitrogen gas is continuously fed into the air inlet F34 of the heat treatment device 3, and the nitrogen gas The flow rate is 4.0L / min.

[0079] BCl was used in the deposition process 3 and NH 3 As the source gas, H 2 As diluent gas, NH 3 Carry out in the deposition furnace from the second gas inlet 21 of vapor deposition device 2, BCl 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com