Preparation method of novel two-dimensional material reinforced polyethylene glycol lubricating oil

A technology of polyethylene glycol and two-dimensional materials, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problem that the friction coefficient and wear rate are not well reduced, the lubrication effect will not be greatly improved, and the transfer Film instability and other problems, to achieve excellent cooling performance, good lubricating effect, excellent mechanical properties and self-lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

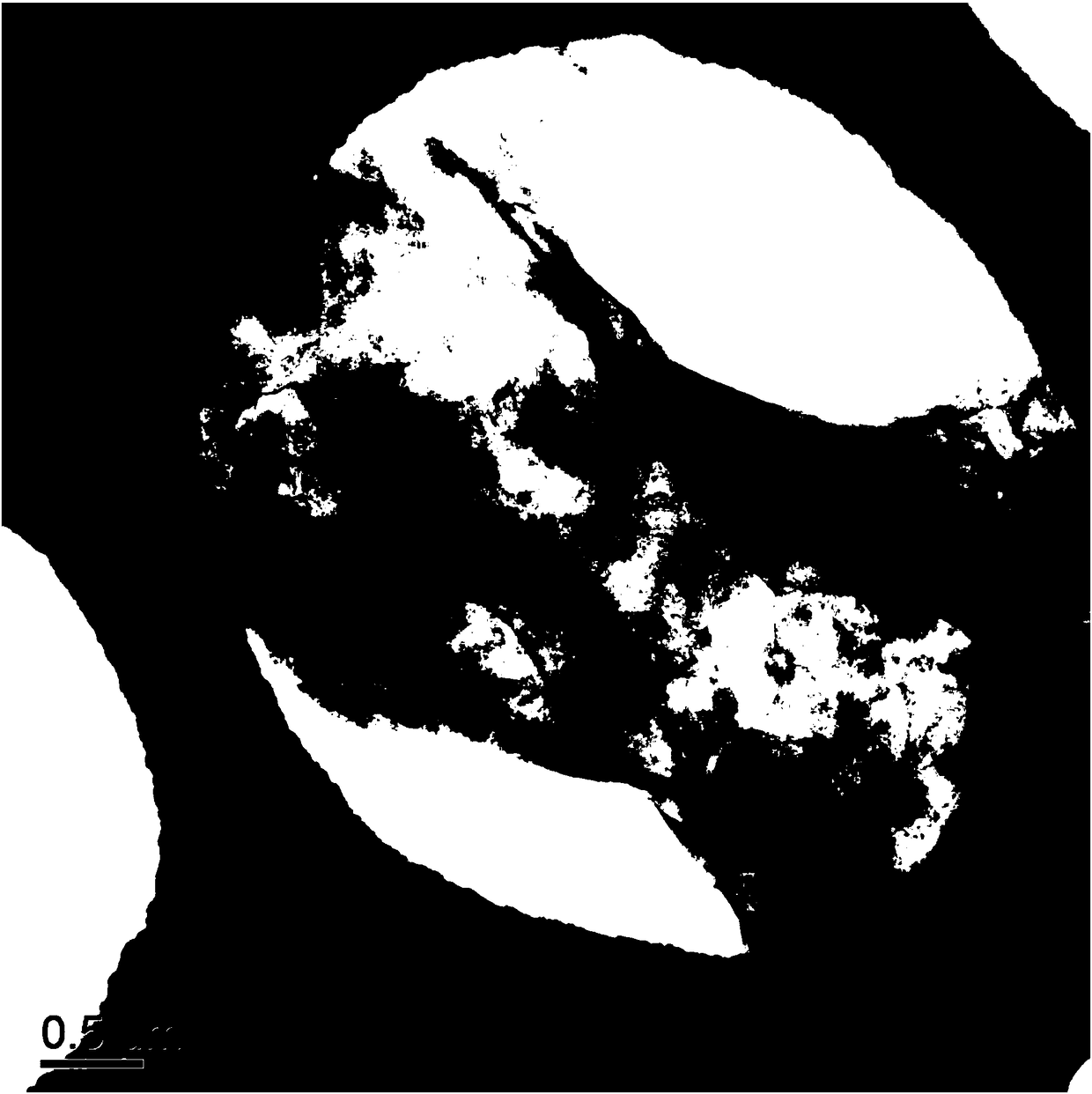

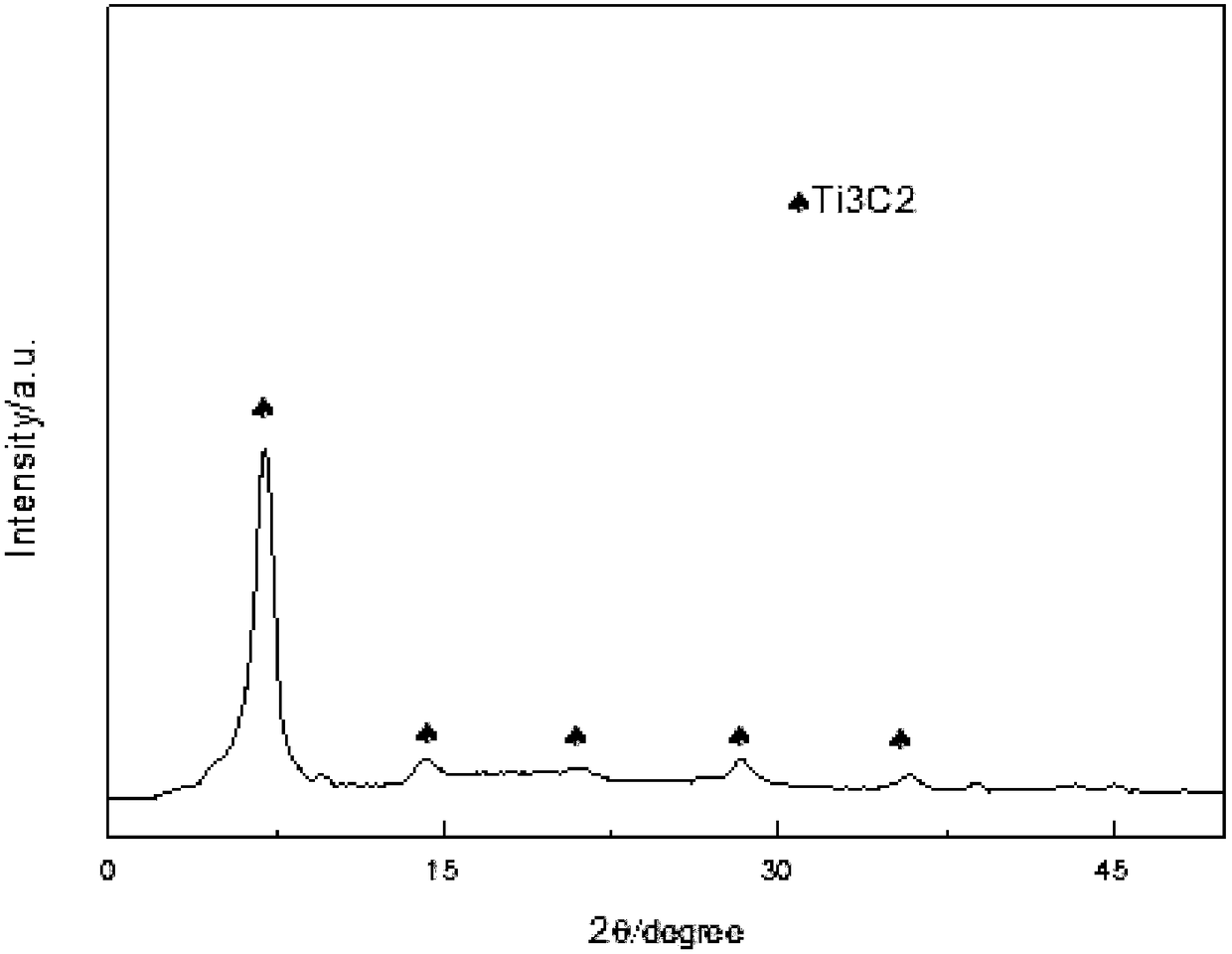

[0025] like Figure 1~2 Shown, a kind of preparation method of novel two-dimensional material reinforced polyethylene glycol lubricating oil comprises the following steps:

[0026] Step 1, adding Ti3AlC2 powder into HF solution for corrosion reaction, magnetic stirring for several hours, then centrifugal washing, and vacuum drying to obtain Ti3C2 powder; wherein, the raw material ratio of the Ti3AlC2 powder is TiC:Ti:Al=1:1 : 1.3; through ball mill mixing for 3 to 10 hours, the ball mill speed is 150 to 250r / min; the sintering temperature is 1350 to 1450°C, then crushed and sieved, and the sieve is set to 200 mesh; The volume ratio is 1g:(2-20)mL, the concentration of HF is 10%-40%, the etching time is 6-20 hours, and it is washed repeatedly with deionized water and ethanol.

[0027] Step 2, mixing the Ti3C2 powder in step 1 with the intercalation solvent, stirring, washing, and drying to obtain the treated Ti3C2 powder; wherein, the intercalation solvent is dimethyl sulfoxid...

Embodiment 1

[0032] (1) Mix 6g of Ti3AlC2 powder with 85mL of HF solution (the volume concentration of HF solution is 10%), stir at room temperature for 4 hours (rotation speed is 200rpm), then centrifugally wash with deionized water twice, and dry at 50°C for 24 Hours, Ti3C2 powder was obtained.

[0033] (2) Mix 5 g of Ti3C2 powder with 20 mL of dimethyl sulfoxide, stir at room temperature for 10 hours (300 rpm), wash with deionized water three times, and dry at 80° C. for 16 hours to obtain the treated Ti3C2 powder.

[0034](3) Dissolve 2 g of the treated Ti3C2 powder in a mixed solution of 300 mL of deionized water, sonicate for 4 hours (ultrasonic power is 300 W), centrifuge (8000 rpm for 20 min), take the supernatant, and freeze-dry to obtain a two-dimensional Ti3C2 (MXene) nanosheets.

[0035] (4) Dissolve two-dimensional Ti3C2(MXene) nanosheets in polyethylene glycol to form a 0.5 mg / ml solution, and stir it ultrasonically for 1 hour to obtain a solution with good dispersibility. ...

Embodiment 2

[0038] (1) Mix 6g of Ti3AlC2 powder with 85mL of HF solution (the volume concentration of HF solution is 10%), stir at room temperature for 4 hours (rotation speed is 200rpm), then centrifugally wash with deionized water twice, and dry at 50°C for 24 Hours, Ti3C2 powder was obtained.

[0039] (2) Mix 5 g of Ti3C2 powder with 20 mL of dimethyl sulfoxide, stir at room temperature for 10 hours (300 rpm), wash with deionized water three times, and dry at 80° C. for 16 hours to obtain the treated Ti3C2 powder.

[0040] (3) Dissolve 2 g of the treated Ti3C2 powder in a mixed solution of 300 mL of deionized water, sonicate for 4 hours (ultrasonic power is 300 W), centrifuge (8000 rpm for 20 min), take the supernatant, and freeze-dry to obtain a two-dimensional Ti3C2 (MXene) nanosheets.

[0041] (4) Use a dropper to take a small amount of solution and drop it between the friction pairs, select the load to be 300g, the rotational speed to be 300r / min, and the time to be 15min.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com