Water-soluble photocuring 3D printing material

A 3D printing and light curing technology, applied in the direction of additive processing, can solve the problems of workpiece warping, large volume shrinkage, deformation, etc., and achieve the effect of reducing shrinkage and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

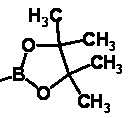

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of acrylic polymer can adopt the conventional method in the art, such as using a catalyst to polymerize the monomer in a solvent. The organic solvent used is preferably alcohol compound, ketone compound, ester compound, ether compound, amide compound, Sulfone compounds, hydrocarbon compounds. The initiator used includes, for example, ketone peroxide compounds such as cyclohexanone peroxide, 3,3,5-trimethylcyclohexanone peroxide, and methyl cyclohexanone peroxide; 1. 1-Di(tert-butylperoxy)-3,3,5-trimethylcyclohexane, 1,1-bis(tert-butylperoxy)cyclohexane, n-butyl-4,4-bis( Tert-butylperoxy)pentanoate, 2,2-bis(4,4-di-tert-butylperoxycyclohexyl)propane, 2,2-bis(4,4-di-tert-pentylperoxycyclohexyl) Propane, 2,-bis(4,4-di-tert-hexylperoxycyclohexyl)propane, 2,2-bis(4,4-di-tert-octylperoxycyclohexyl)propane, 2,2-bis(4, Peroxyketal compounds such as 4-dicumylperoxycyclohexyl)propane; hydroperoxides such as cumene hydroperoxide, 2,5-dimethylhexane-2,5-dihyd...

Embodiment 1

[0062] The 3D printing material includes the following components: 100 parts by weight of polyester acrylate M-8060, 30 parts by weight of triethylene glycol di(meth)acrylate, 20 parts by weight of water-soluble polyurethane acrylate A1, 1 part by weight of initiator Agent. Through the workpiece shrinkage test, the shrinkage rate of the 3D printing material is 0.25%.

Embodiment 2

[0064] The 3D printing material includes the following components: 100 parts by weight of polyester acrylate M-8060, 30 parts by weight of triethylene glycol di(meth)acrylate, 20 parts by weight of water-soluble polyurethane acrylate A2, 1 part by weight of initiator Agent. Through the workpiece shrinkage test, the shrinkage rate of the 3D printing material is 0.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com