Combined treatment method for HEDP copper plating wastewater

A treatment method and wastewater technology, which are applied in metallurgical wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of large equipment area and complicated HEDP copper plating wastewater treatment process, and achieve equipment occupying Small land area, good market application prospects, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

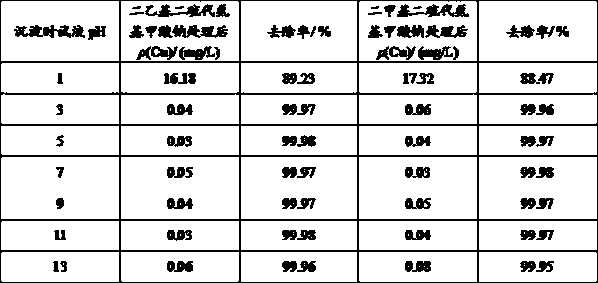

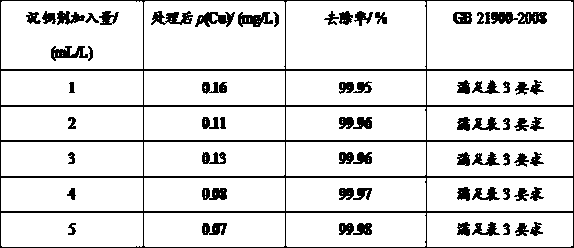

[0039] Embodiment 1: Regulate pH treatment HEDP copper plating wastewater with lime emulsion

[0040] Step 1. Precipitation

[0041] Treat HEDP copper-plating wastewater containing 300 mg / L copper, 5000 mg / L HEDP, and 200 mg / L potassium sodium tartrate, and store the wastewater in the HEDP copper-plating wastewater regulating tank. The wastewater flows from the HEDP copper plating wastewater adjustment tank into the precipitation reaction tank A, stirs the tank liquid, adds lime emulsion to adjust the pH of the wastewater to 10-12, and adds 30 L of calcium chloride solution to each ton of wastewater; the wastewater flows from the precipitation reaction tank A Flow into the precipitation reaction tank B, and then add 2 L of sodium diethyldithiocarbamate solution per ton of waste water under stirring.

[0042] Step 2, Sediment Separation

[0043] The wastewater flows from the sedimentation reaction tank B into the flocculation tank, and the flocculant is added under the stirri...

Embodiment 2

[0050] Embodiment 2: Regulate pH with sodium hydroxide and process HEDP copper plating wastewater

[0051] Step 1. Precipitation

[0052] Treatment of HEDP copper plating wastewater containing copper 150 mg / L, HEDP 2500 mg / L, potassium sodium tartrate 100 mg / L. The wastewater flows from the HEDP copper plating wastewater adjustment tank into the precipitation reaction tank A, stirs the tank liquid, adds sodium hydroxide solution to adjust the pH of the wastewater to 10-12, and adds 40 L of calcium chloride solution to each ton of wastewater; the wastewater from the precipitation reaction Pool A flows into precipitation reaction pool B, and then add 2 L of sodium dimethyl dithiocarbamate solution per ton of waste water under stirring.

[0053] Step 2, Sediment Separation

[0054] The wastewater flows from the sedimentation reaction tank B into the flocculation tank, and the flocculant is added under the stirring condition. The amount of the flocculant added can make the sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com