Metamaterial based on liquid metal microfluidics and preparation method thereof

A liquid metal and metamaterial technology, applied in electrical components, antennas, etc., can solve problems such as structural shape and material properties that cannot be dynamically adjusted, and achieve the effects of improving application performance, optimizing structure, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

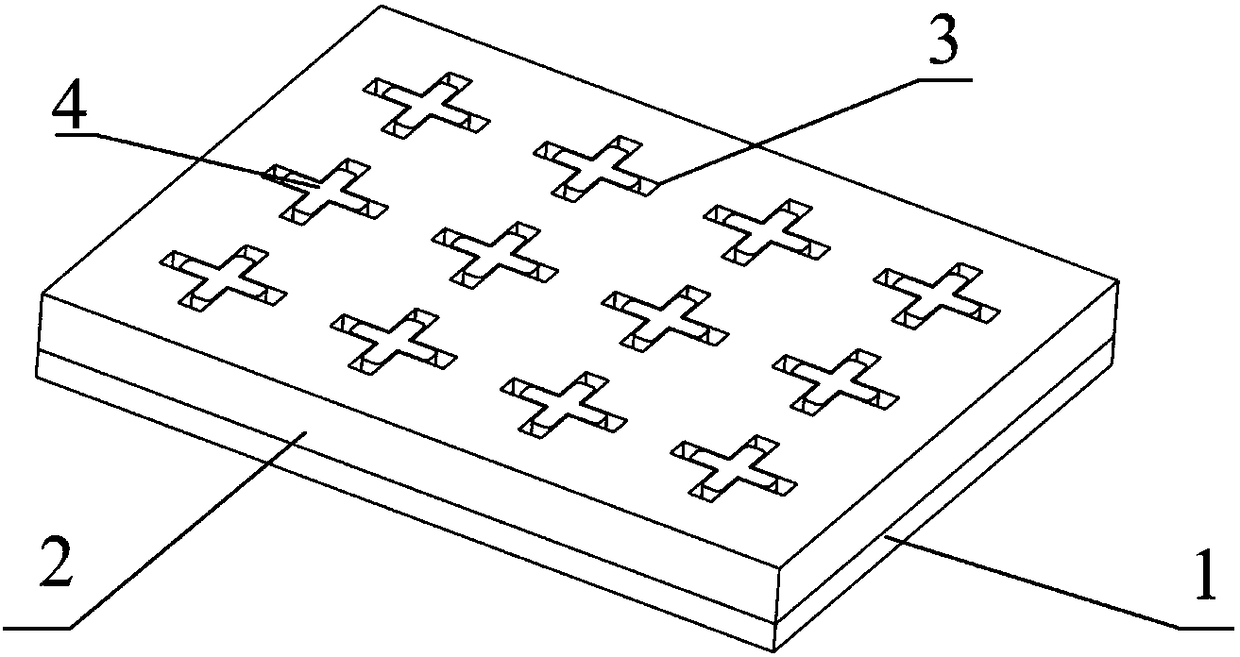

[0051] Such as figure 1 As shown, a specific embodiment of the present invention discloses a metamaterial based on liquid metal microfluidics, which includes a bottom metal layer, an intermediate dielectric layer and a microchannel array arranged on the surface of the intermediate dielectric layer.

[0052] The bottom metal layer and the intermediate dielectric layer are fixed film layers. The intermediate dielectric layer includes a dielectric material for isolation.

[0053] Optionally, the bottom metal layer can be selected from metal thin film materials such as silver and copper, and the intermediate dielectric layer can be selected from at least one of silicon dioxide, silicon, aluminum oxide, silicon rubber, and polydimethylsiloxane (PDMS) Species, or other materials suitable for the metamaterial intermediate layer.

[0054] Liquid metal is arranged in the microchannel, and the liquid metal flows in the microchannel to form a metal microstructure on the surface of the metamate...

Embodiment 2

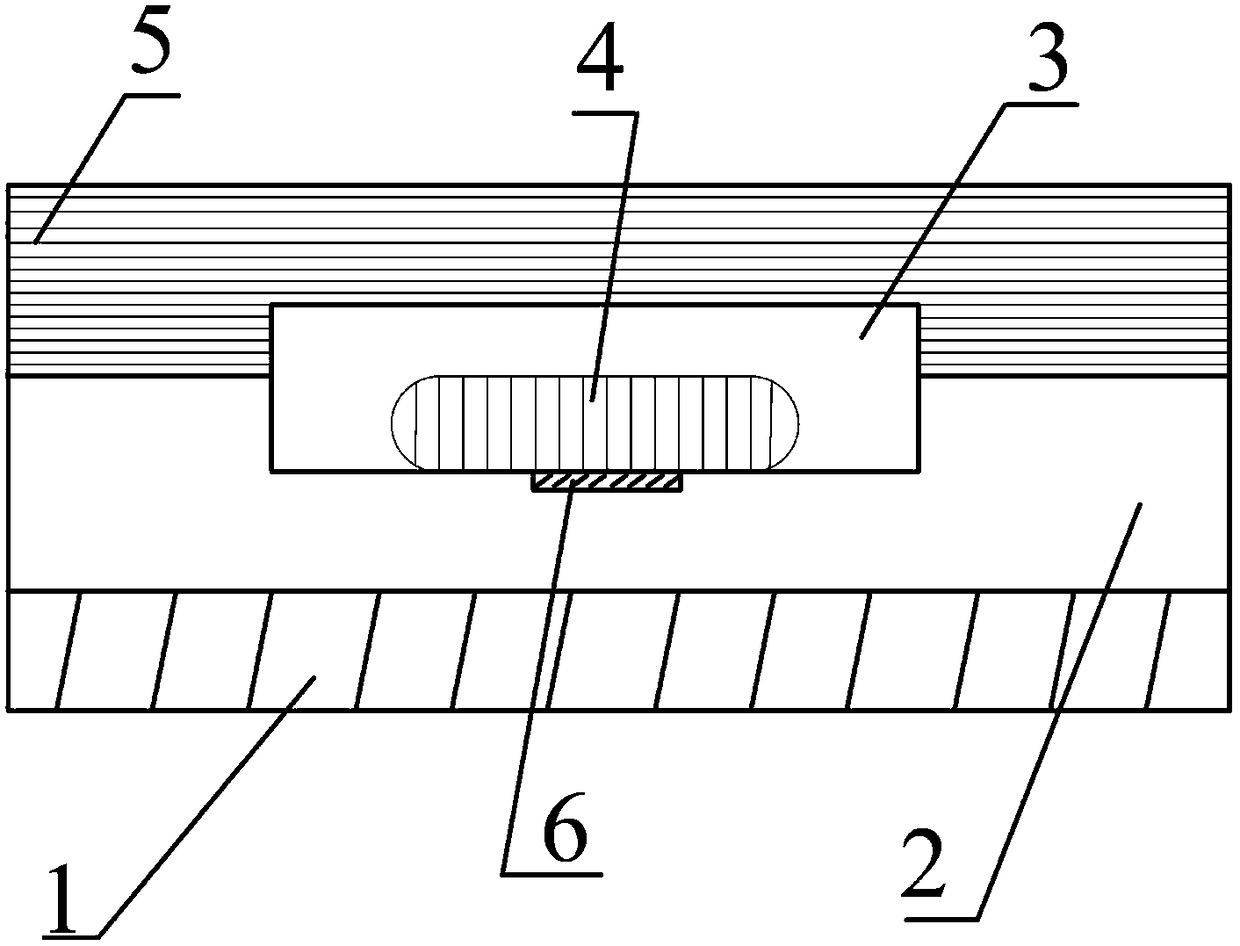

[0059] Such as figure 2 As shown, optimized on the basis of the above embodiment, the liquid metal uses gallium or gallium alloy, such as gallium indium alloy, gallium indium tin alloy, and is driven by external force to realize the flow in the microstructure and form the metal of the metamaterial surface layer. microstructure. Through the arbitrary fluidity of liquid gallium or gallium alloy, microfluidization of liquid gallium or gallium alloy can realize micro-flow control of metamaterials. The technology is applied to the reconstruction of the structural parameters and structural morphology of metamaterials, which have the ability to regulate their physical properties.

[0060] In an air environment, liquid metal easily interacts with air to form an oxide layer on the surface of the liquid metal. The thickness of the oxide layer is 3-5nm, which should be removed during processing. Before injecting liquid metal into the microchannel structure, the channel structure should be...

preparation Embodiment 2

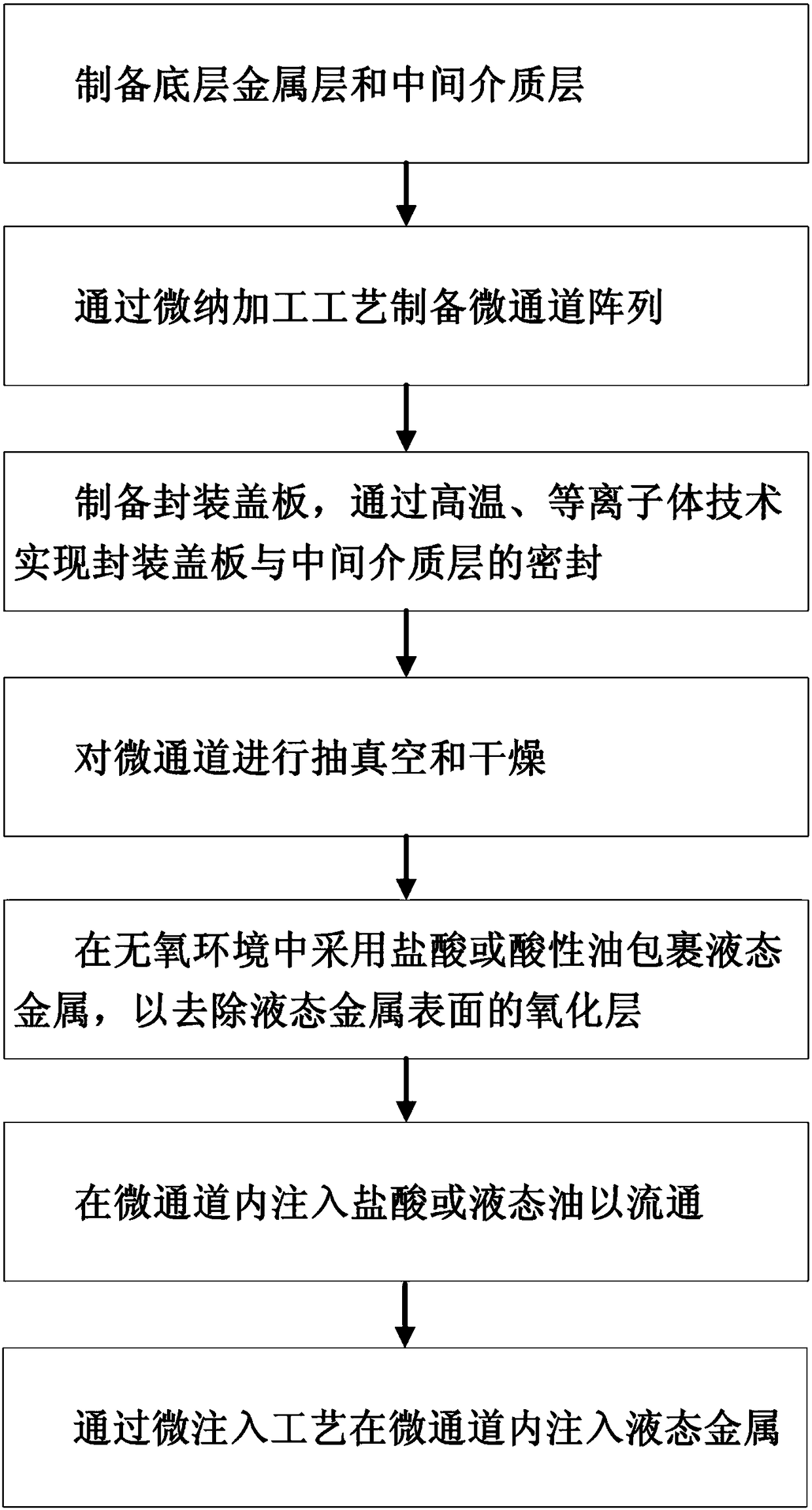

[0069] A method for preparing the metamaterial described in Example 2 specifically includes the following steps:

[0070] 1. Prepare the bottom metal layer and the intermediate dielectric layer by magnetron sputtering process or chemical vapor deposition method. The bottom metal layer is made of metal thin film materials such as silver or copper, and the intermediate dielectric layer is made of silicon dioxide, silicon, and aluminum oxide silicon. At least one of rubber, PDMS and other materials;

[0071] 2. Micro-channel arrays are prepared by micro-nano processing technology, which includes photolithography, nano-imprinting, etc., and each micro-channel is prepared by any of screen printing, coating, magnetron sputtering, PECVD, etc. The base

[0072] 3. Use a vacuum oven to cure PDMS at a temperature of 70-100°C to prepare a package cover, and then use high temperature and plasma technology to seal the package cover and the intermediate dielectric layer;

[0073] 4. Dry the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com