Embedded rubber water stop band with transverse built-in reinforcing ribs

A technology of rubber waterstops and waterstops, which can be applied in shaft linings, tunnel linings, underground chambers, etc., can solve the problems of increasing construction time, delaying construction progress, and small lateral rigidity, so as to enhance anchoring ability and waterproof ability , Facilitate storage and transportation, reduce resistance and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

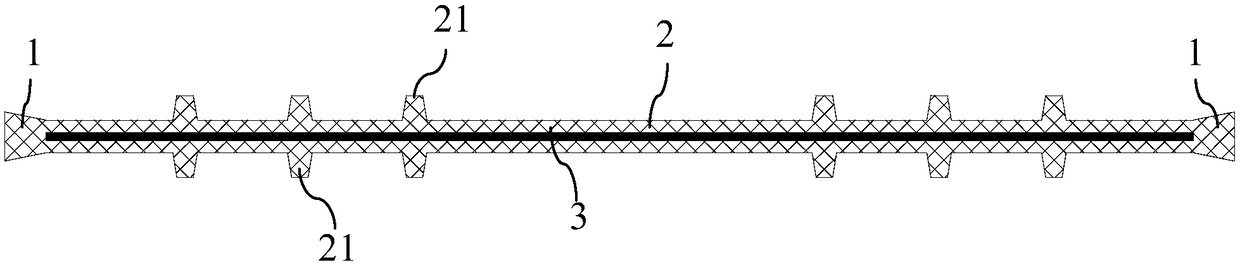

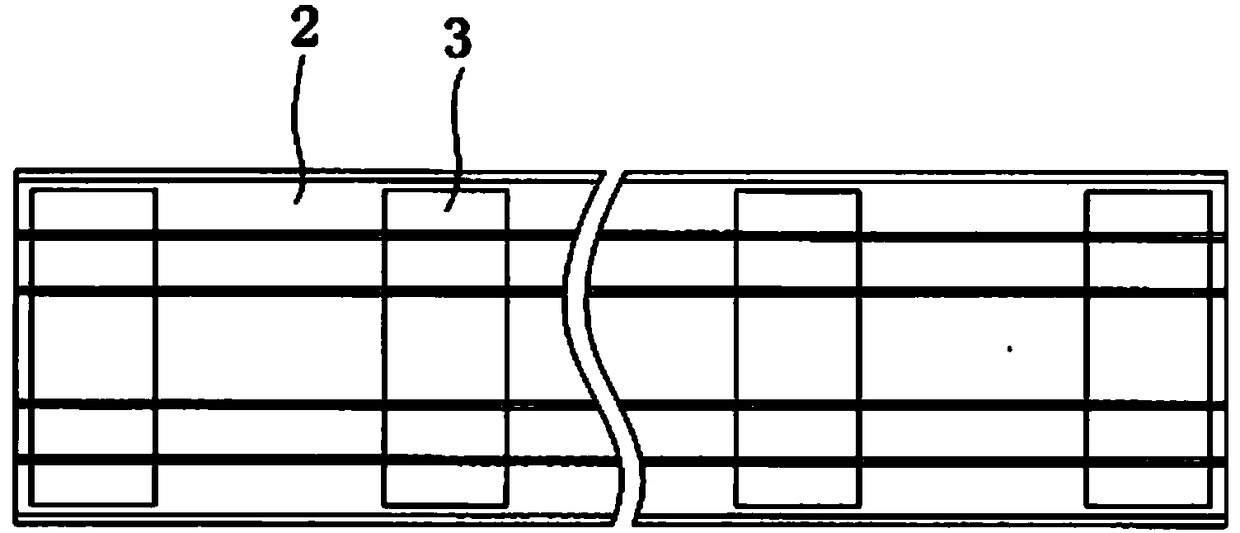

[0044] Such as Figure 1-2 As shown, the rubber waterstop provided by an embodiment of the present invention includes a waterstop body 2 .

[0045] Wherein, along the width direction of the waterstop body 2 , two sides of the waterstop body 2 respectively have clips 1 .

[0046] Wherein, a plurality of reinforcing plates 3 are arranged at intervals along the length direction of the waterstop body 2 inside the waterstop body 2 .

[0047] Wherein, there is a certain distance between any two adjacent reinforcement plates 3 , and each reinforcement plate 3 extends along the width direction of the waterstop main body.

[0048] The reinforcing plate 3 can be a supporting plate such as a plastic plate, a metal plate, and any plate with a supporting and reinforcing effect can be used as a reinforcing plate, not limited to a metal plate, a plastic plate, and the like. The reinforcing plate 3 is preferably made of Q235 carbon steel with a thickness of 2mm.

[0049] The thickness of t...

Embodiment 2

[0056] Such as Figure 1-2 As shown, the structural diagram of the transversely reinforced mid-buried rubber waterstop provided by the present invention, the transversely reinforced mid-buried rubber waterstop provided by the present invention includes a waterstop body 2 with chucks 1 on both sides, and Stiffeners 3 are arranged at intervals inside the hose body 2 , and the distance between the stiffeners 3 is 2-7 times the width of the stiffeners 3 . Stiffeners are installed inside to provide lateral rigidity for the waterstop. During the construction process, especially during the pouring of concrete, it is ensured that the waterstop remains horizontal without external devices, which enhances the waterstop. The anchoring ability and waterproof ability of the belt also reduce the construction time of the installation device and eliminate the safety hazard of "dropping blocks"; the controllability of the spacing of the stiffening plates can be adjusted by changing the spacing ...

Embodiment 3

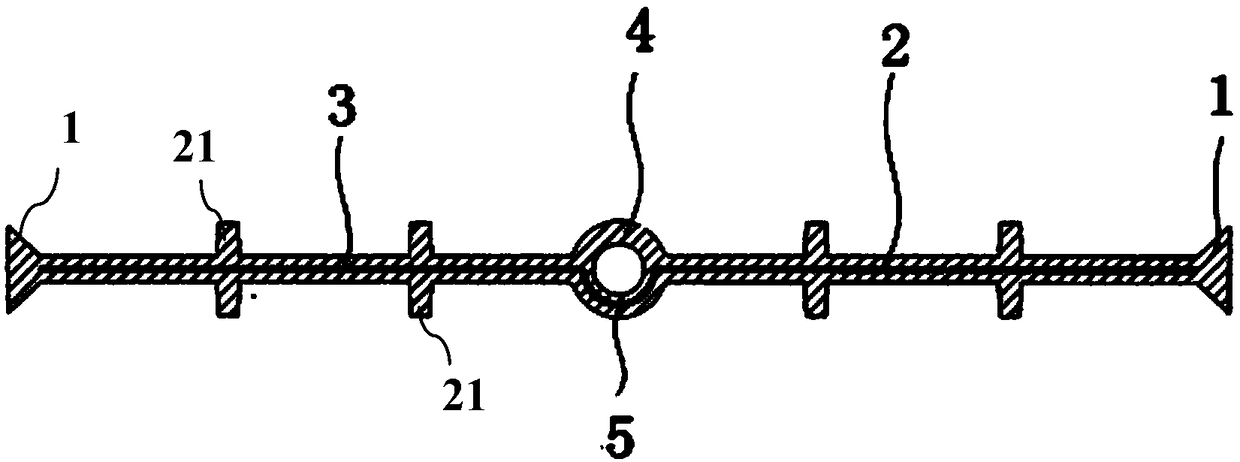

[0059] Such as Figure 3-4 As shown, the rubber waterstop provided by the present invention includes a waterstop body 2 .

[0060] Wherein, along the width direction of the waterstop body 2 , two sides of the waterstop body 2 respectively have clips 1 .

[0061] Wherein, a plurality of reinforcing plates 3 are arranged at intervals along the length direction of the waterstop body 2 inside the waterstop body 2 .

[0062] A deformable deformation ring 4 is provided on the waterstop body 2 , and a reinforcement plate bending section 5 is correspondingly provided on a position corresponding to the deformation ring 4 on the reinforcement plate 3 , and the reinforcement plate bending section 5 is located in the deformation ring 4 .

[0063] This embodiment is a further improvement on the technical solution of the first embodiment.

[0064] The rubber waterstop provided in this embodiment is a cracked waterstop. By providing a deformation ring 4 on the waterstop body 2, when the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com