Aqueous emulsions containing ethylene-vinyl acetate copolymers, preparation process thereof and their use as Anti-gelling additives of crude oils

A vinyl acetate and water-based emulsion technology, which can be used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., and can solve problems such as low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] Accordingly, another form of the invention is a process for the preparation of an aqueous emulsion as described and claimed in this disclosure, the process comprising the steps of:

[0088] i. High boiling organic solvents or mixtures thereof, primary emulsifiers, at a temperature which must be above the highest melting point of all polymers present and wherein the ratio between said polymer and said organic solvent is at least 1 / 1 Precursors (preferably organic acids), ethylene-vinyl acetate copolymers and / or polyalkyl (meth)acrylates are mixed together to form an organic solution;

[0089] ii. cooling said organic solution at a temperature less than or equal to 95°C, or pressurizing under a pressure sufficient to avoid rapid evaporation of water;

[0090] iii. Adding an aqueous alkaline solution to said cooled or pressurized solution to completely neutralize the organic acid present, thereby creating a primary emulsifier and forming an inverse emulsion comprising an a...

Embodiment 1

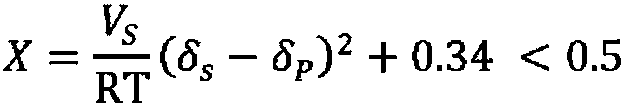

[0116] In a glass reactor, at 110°C, xylene (δ=18MPa 1 / 2 ), heat-dissolve a mixture of 6 parts of oleic acid and 100 parts of ethylene-vinyl acetate resin as a pour point depressant. Copolymer of VA and 25 g / 10' (72%) flow index, EVA copolymer composition characterized by 40% VA and 60 g / 10' (14%) flow index. The copolymer / solvent ratio is equal to 1 / 1. The mixture was cooled at 90° C. to achieve complete neutralization before adding 16 parts of 7.5% KOH solution. Then 185 parts of deionized water containing 1 part of the anionic surfactant, alkyl-diphenyl ether disulfonate (sodium dodecyl diphenyl ether disulfonate) was added at room temperature. At 25% active phase (ie pour point depressant additive) an emulsion was obtained in which the dispersed phase was characterized by an average particle size of about 1.3 [mu]m.

Embodiment 2

[0118] Use the distillate of high boiling point aromatic solvent as solvent (δ=17.5-18MPa 1 / 2 ,T eb =179° C.), ie heavy aromatic naphtha, was prepared in the same manner as described in Example 1.

[0119] At 25% active phase an emulsion was obtained in which the dispersed phase was characterized by an average particle size of about 950 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com