Preparation method of nitrogen-doped carbon-coated zinc telluride nanometer wire and application thereof serving as sodium-ion battery negative electrode material

A technology of nitrogen-doped carbon and nanowires, applied in battery electrodes, negative electrodes, nanotechnology, etc., can solve the problems of batteries not having cycle performance, material morphology damage, etc., to improve conductivity, stability, and cycle performance Good, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

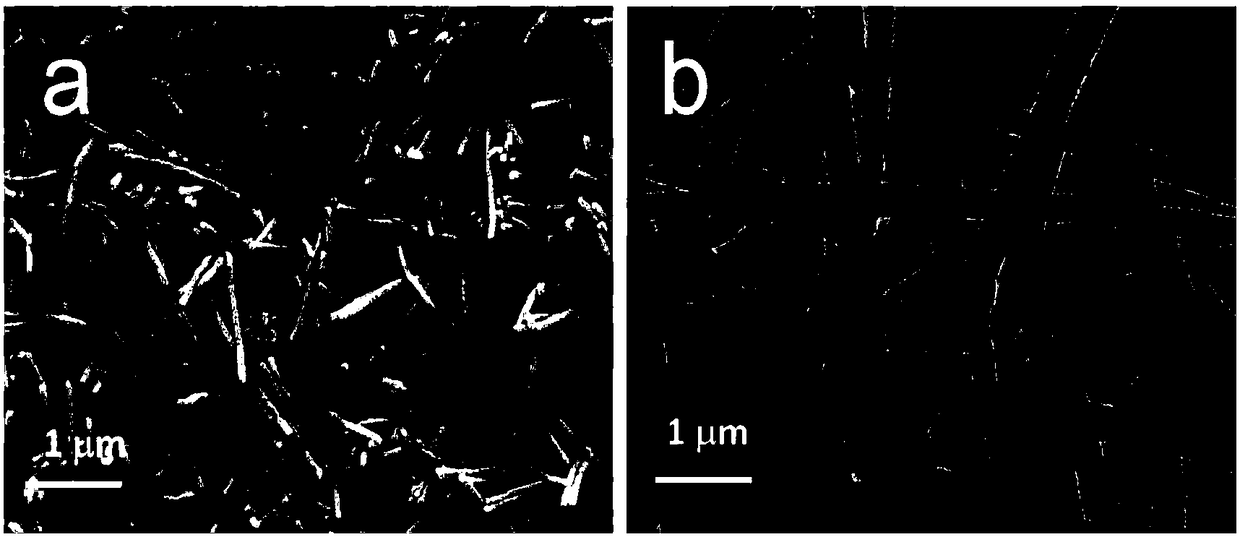

Image

Examples

Embodiment 1

[0039] In this example, a nitrogen-doped carbon-coated zinc telluride nanowire composite material was prepared according to the following steps:

[0040] 1. Add 0.0922g Na 2 TeO 3Dissolve 1g of PVP in 18mL of ethylene glycol, then add 15mL of acetone, 3.35mL of ammonia water and 1.65mL of hydrazine hydrate in turn, stir at room temperature until completely dissolved, then put the mixed solution into a polytetrafluoroethylene liner, and then put Stainless steel high-temperature and high-pressure reaction kettle, heated at 180°C for 4 hours; after the reaction was completed, cooled to room temperature, centrifuged and washed with acetone to obtain Te nanowires;

[0041] 2. Add the Te nanowires obtained in step 1 into 30mL of ethylene glycol, stir ultrasonically until uniformly dispersed, then add 10mL of ethylene glycol solution in which 0.2g of silver nitrate is dissolved, stir at room temperature for 1h, centrifuge after the reaction is over and use a deionized Washed with w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com